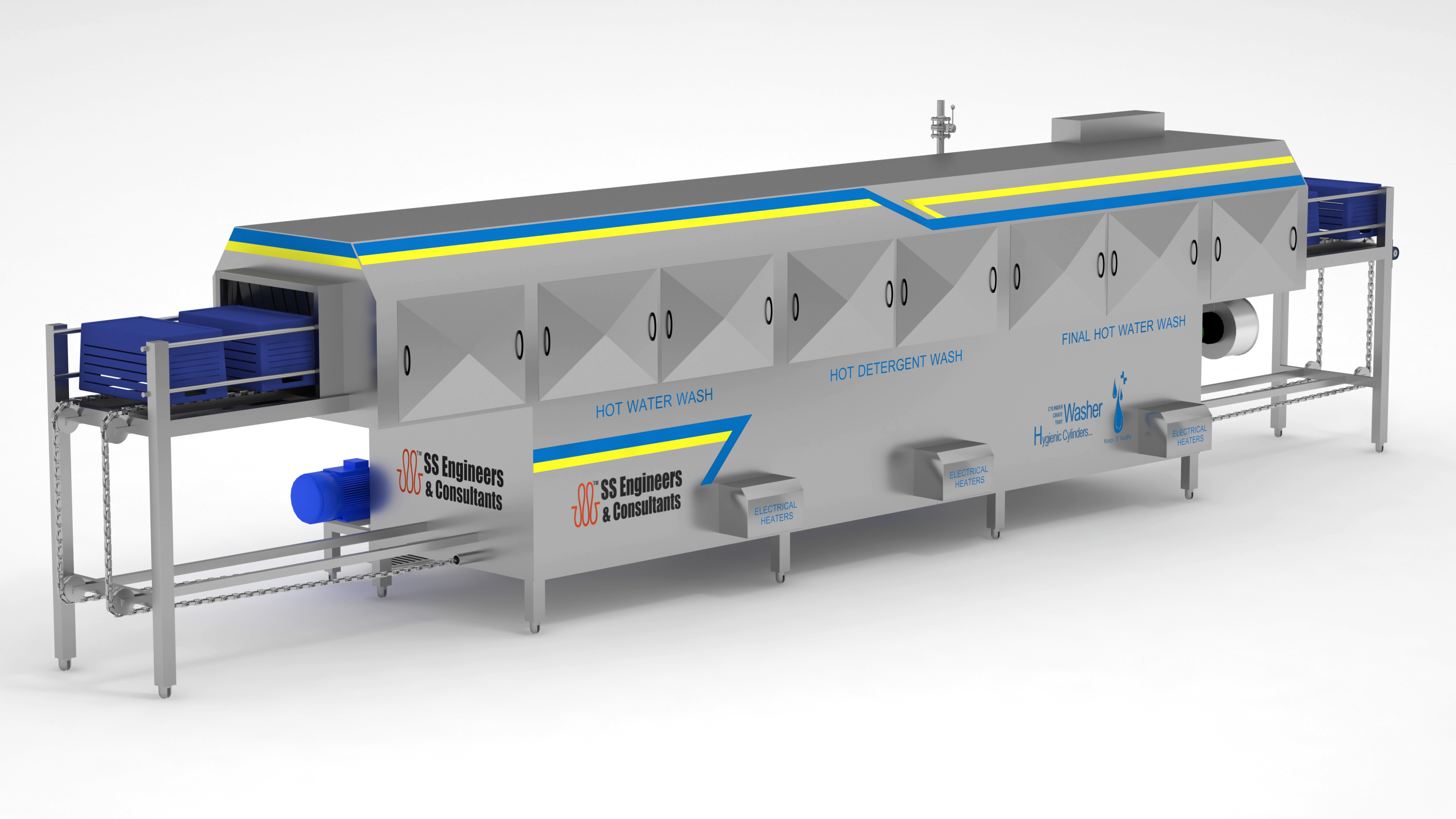

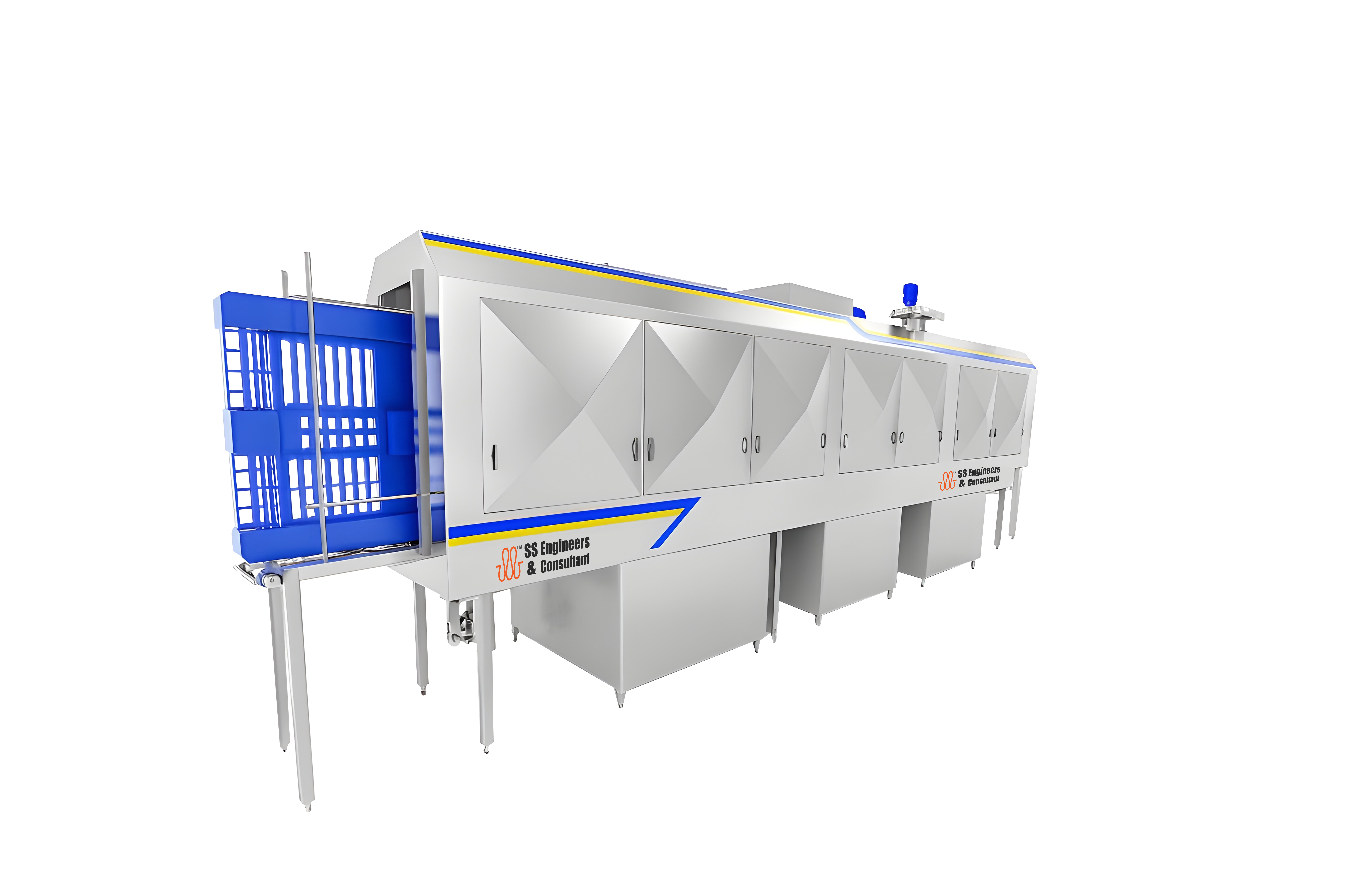

Crate Washer

Our Crate Washer is engineered for hygienic, high-throughput cleaning of plastic crates, trays, and bins used in fruits, vegetables, and food processing industries. The machine follows a multi-stage process—pre-rinse → detergent wash → final rinse → optional hot sanitization → high-velocity air drying—ensuring removal of mud, pesticides, residues, and organic matter while minimizing water and chemical consumption through recirculation and filtration.

With powerful spray nozzles, adjustable conveyor speed, and recipe-based controls, the system effectively handles diverse soils such as dust, mud, sap, starch, and sticky fruit pulp without cross-contamination. Its SS304/316 stainless steel build, inline filtration, and automatic chemical dosing provide durability, lower operating costs, and easy maintenance. The washer delivers a typical capacity of up to 500 crates/hour, scalable with multi-lane options, making it ideal for centralized washing near sorting, grading, and packing areas.

Designed to meet HACCP, FSMS, and GMP standards, the crate washer supports strict hygiene requirements in fresh produce, frozen food, and agro-processing plants. Optional features include hot-water/steam sanitization, air-knife blow-off systems for rapid drying, heat recovery units, and integrated conveyors or stacking/destacking units for fully automated operation. User-friendly PLC/SCADA controls allow operators to monitor cycles, track efficiency, and switch easily between different crate or tray sizes.

By combining robust construction, automation, and efficient resource use, SS Engineers & Consultants’ Crate Washer helps fruit and vegetable processors reduce labor, improve turnaround times, and maintain consistent hygiene—ensuring clean, safe, and ready-to-use crates for every harvest and packaging cycle.

Pallet Washer

Our Pallet Washer is engineered for efficient cleaning and sanitization of plastic and wooden pallets used in fruits, vegetables, agro-processing, cold storage, and export operations. The system ensures removal of mud, soil, sap, pesticide residues, and organic matter that accumulate during harvest handling, storage, and transport. Its multi-stage process—pre-rinse → detergent wash → final rinse → optional hot sanitization → air drying—delivers consistent results while conserving water and chemicals with closed-loop filtration and recirculation.

The system features inline filtration, automatic chemical dosing, and energy-efficient heating to reduce OPEX while maintaining strict hygiene standards. With a typical capacity of 100–250 pallets/hour (scalable with multi-lane designs), it is ideal for centralized washing stations in sorting/grading centers, pack houses, cold storages, and export hubs. PLC/SCADA automation allows operators to run recipe-based programs for different pallet sizes and soil levels, with real-time monitoring and cycle logging.

Optional add-ons include air-knife blow-off systems for quick drying, heat recovery units for energy savings, and automated pallet infeed/outfeed conveyors for seamless integration into pack house or cold chain operations. Designed to meet HACCP, FSMS, and international hygiene standards, SS Engineers & Consultants’ Pallet Washer helps the fruits and vegetables industry ensure consistent cleanliness, reduce manual labor, extend pallet life, and improve food safety throughout the supply chain.

The Conveyor Systemis designed to integrate seamlessly with fruit and vegetable washers, graders, peelers, and packing lines to ensure smooth, hygienic, and efficient material flow. We supply modular belt, roller, chain, gravity, Z-elevators, curved, and accumulation conveyors with smart controls for singulation, merging, diverting, and buffering of crates or loose produce. VFD-driven motors and PLC logic synchronize speeds to prevent damage, reduce bottlenecks, and protect delicate items like tomatoes, mangoes, and leafy greens.

Layouts can include inspection stations, reject spurs, grading tables, and crate return loops. Stainless steel frames with food-grade belts, wash-down designs, and tool-less access ensure easy sanitation and compliance with international hygiene standards. The conveyors are engineered to handle wet, sticky, and fragile produce without contamination, reducing handling time and labor.

By offering customized designs for pack houses, cold storage facilities, and export hubs, our conveyor systems become the backbone for fruit and vegetable processing lines. Optional features include integrated weighing, automatic counting, robotic pick-and-place units, and automated palletizing, enabling processors to scale operations efficiently.

With robust construction, automation, and food-safe designs, SS Engineers & Consultants’ Conveyor System helps the fresh produce industry improve throughput, minimize product loss, and maintain consistent quality from field to market.