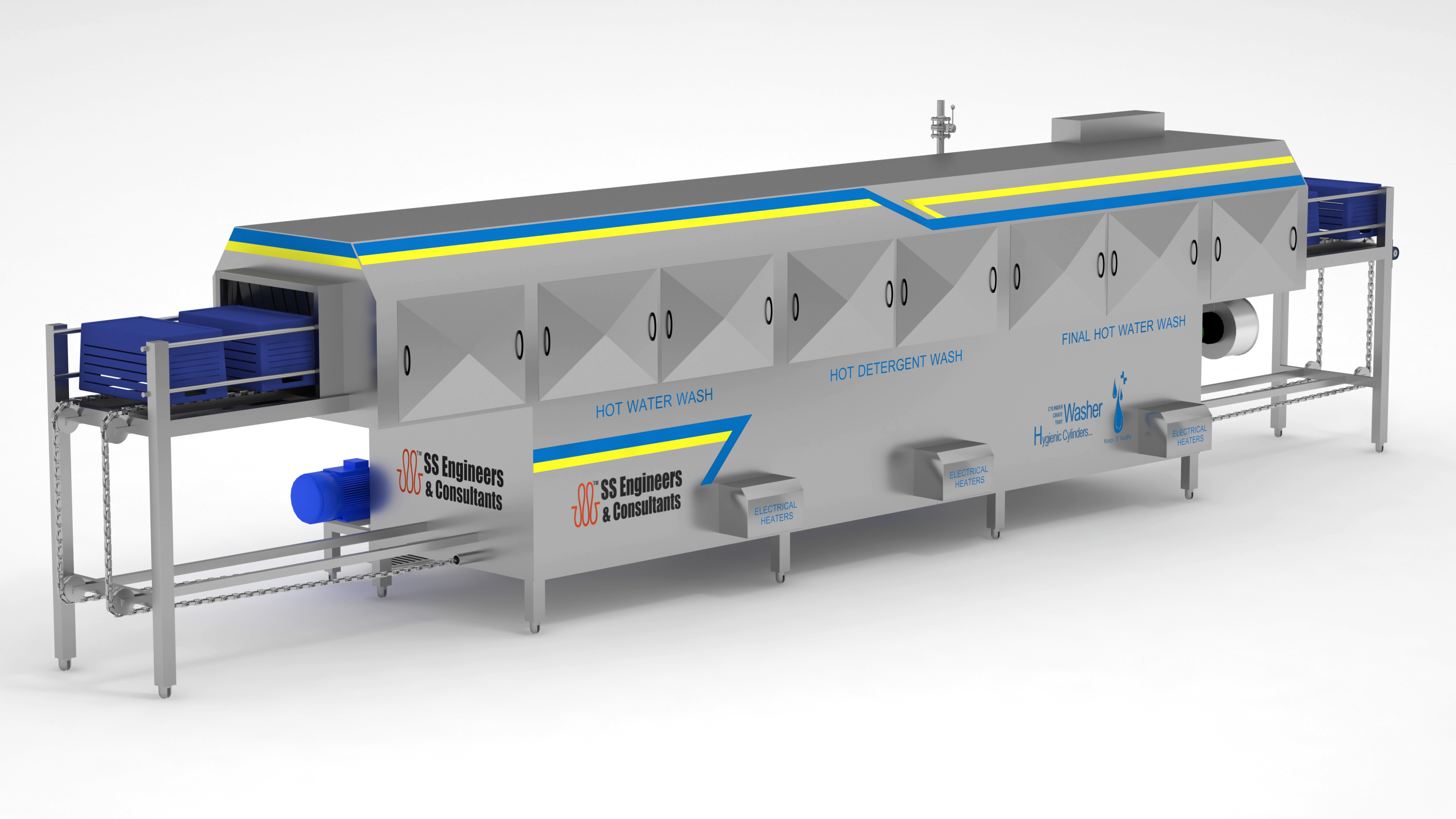

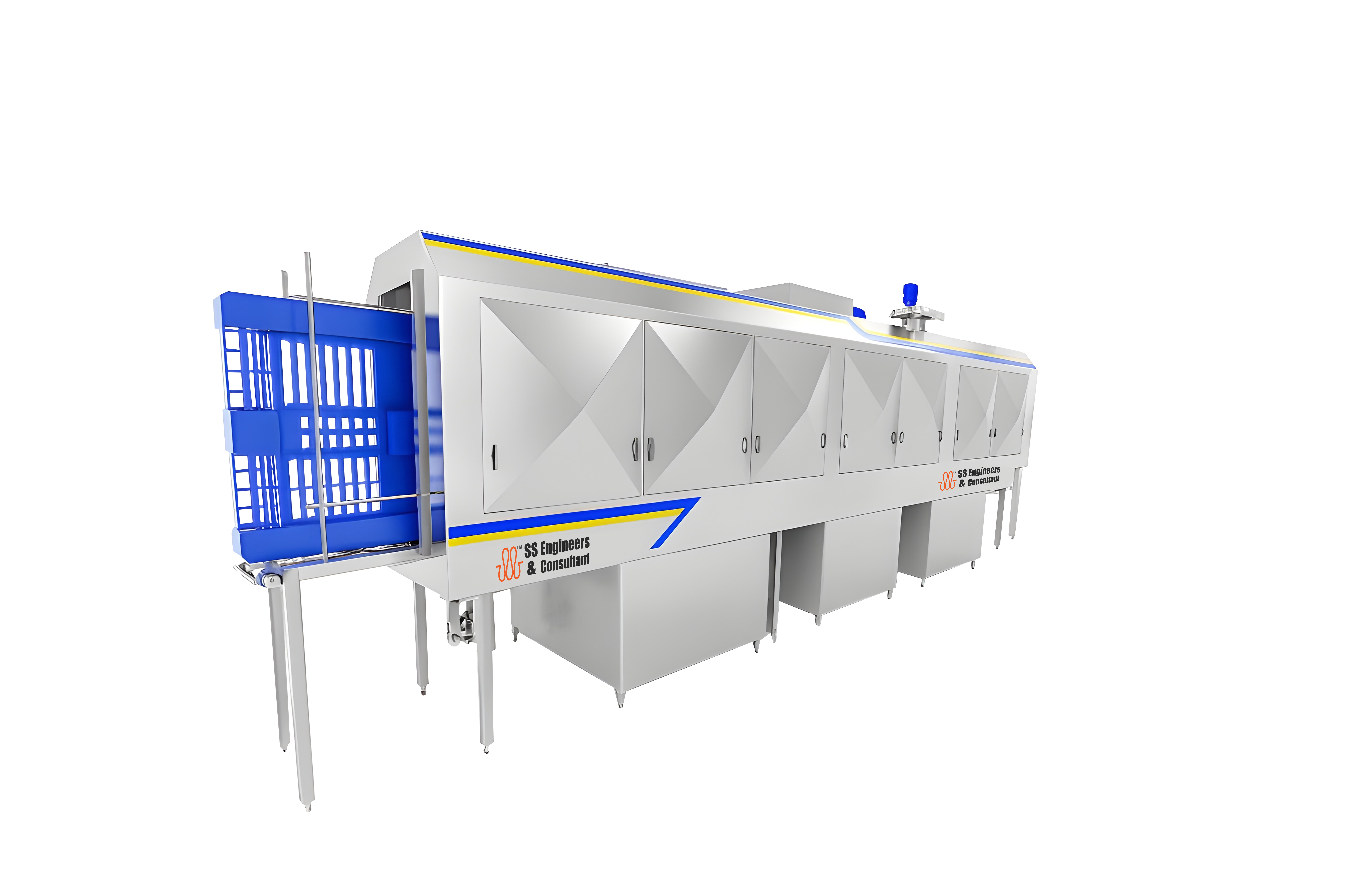

Conveyor System

SS Engineers & Consultants provide advanced conveyor systems purpose-built for

fruits and vegetables processing lines. Constructed in SS304/316 with food-grade belts

and sanitary welds, these conveyors are designed for washing, grading, sorting, and packing

operations,

ensuring gentle handling of delicate produce such as mangoes, tomatoes, onions, and leafy greens.

Configurations

include straight runs, Z-elevators, curves, and accumulation conveyors, all engineered to improve

throughput and

reduce manual handling.

Key features include adjustable conveyor speeds with VFDs, PLC/SCADA automation for

recipe-based

operations, and integration with upstream washers and downstream packing lines. Hygienic sloped frames

allow full

drainage, while modular food-grade belts simplify cleaning and maintenance. The design minimizes product

loss,

ensures smooth flow, and maintains consistent hygiene standards across different stages of produce

processing.

Optional add-ons include inspection platforms, reject spurs, weighing systems, robotic

pick-and-place, and palletizing units,

enabling end-to-end automation in pack houses, cold storages, and export hubs. Fully compliant with

HACCP, FSMS, and GAP standards, SS Engineers & Consultants’ Conveyor System helps

the fruits

and vegetables industry optimize efficiency, reduce labor costs, and protect product quality

from field to market.

Key Features:

- SS304/316 stainless steel construction with food-grade modular belts and hygienic design

- Custom layouts including straight, Z-elevators, curved, and accumulation conveyors

- Gentle handling to prevent bruising or damage to delicate fruits and vegetables

- Recipe-based PLC/SCADA programs for different produce types and load conditions

- Adjustable conveyor speeds with VFD control for smooth integration across lines

- Optional inspection tables, reject spurs, and grading stations for quality assurance

- Inline cleaning-friendly design with sloped frames and quick-access maintenance features

- Integration with washing, sorting, packing, and palletizing systems for end-to-end automation

- Compliant with HACCP, FSMS, and GAP standards for food safety and export readiness

See it in Action

Youtube Video Auto Playing without sound

Need Custom Solutions?

Our team can develop specialized cleaning solutions tailored to your bakery hygiene requirements.

Contact Our Experts