Cage Rotation Part Washer

At SS Engineers & Consultants, our Cage Rotation Part Washer is engineered for precision cleaning of automotive, aerospace, and general engineering parts. Designed with a rotating cage mechanism, the system ensures 360° exposure of components during the wash cycle, allowing uniform cleaning of complex geometries, blind holes, and internal surfaces. The validated multi-stage process of pre-rinse → detergent wash → high-pressure rinse → optional hot sanitization → hot-air or air-knife drying guarantees removal of oil, grease, machining chips, and stubborn residues.

The washer integrates cage rotation technology, customized spray manifolds, and recipe-driven wash programs to handle a wide range of parts — from small precision components to bulky castings. Built in robust SS304/316 with inline filtration and automated chemical dosing, the system supports ISO, CE, and industry-specific cleaning standards. Optional ultrasonic cleaning modules and heat recovery units further enhance performance for critical applications.

With a throughput capacity of up to 300–600 parts/hour (depending on size and load configuration), this washer is ideal for centralized cleaning stations in automotive OEMs, component suppliers, aerospace workshops, heavy engineering plants, and tool rooms. SS Engineers & Consultants delivers reliable, automation-driven washing solutions that minimize downtime, reduce operating costs, and ensure validated, repeatable cleaning results for high-value industrial components.

Dip Type Basket Washer(Basket Bubble Washer)

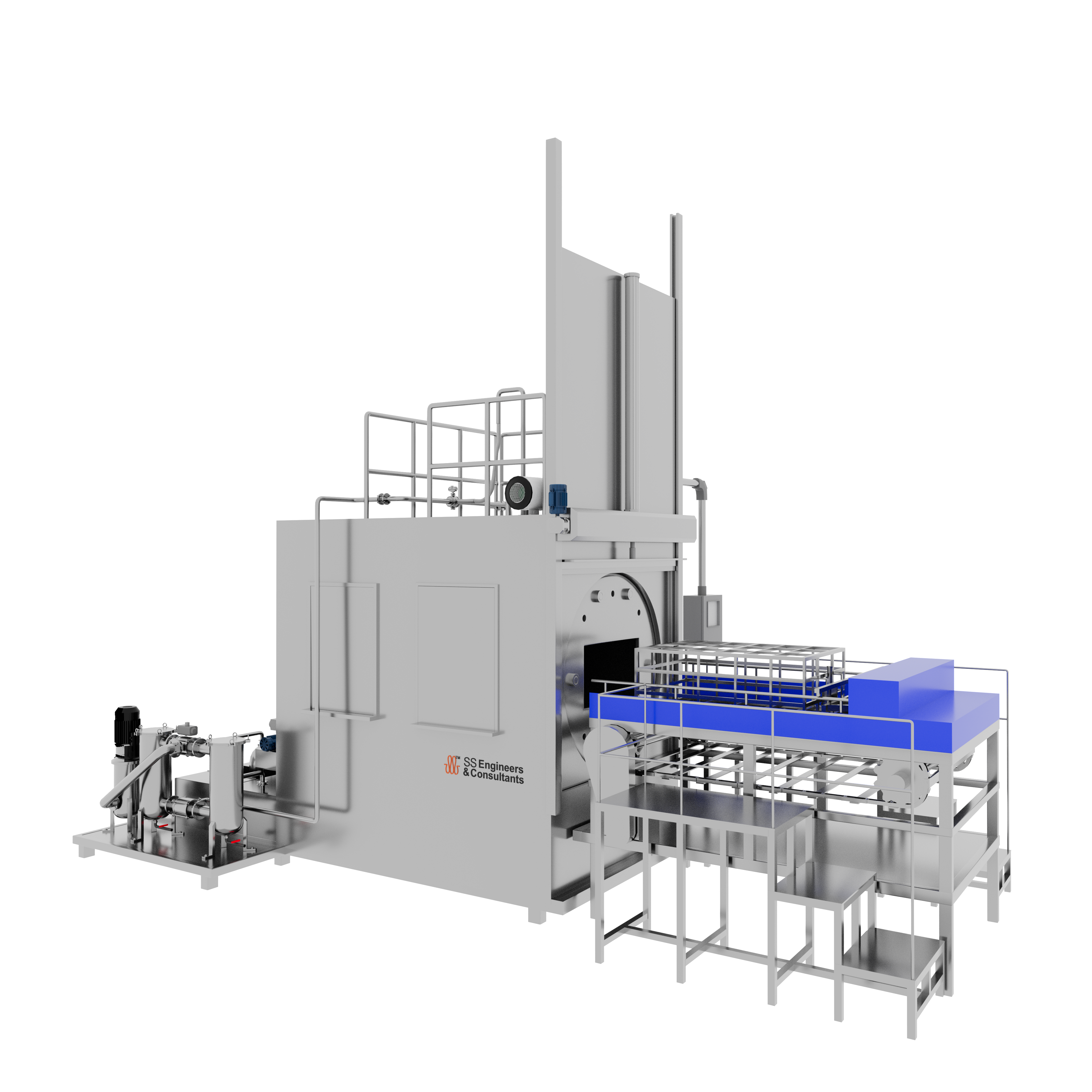

At SS Engineers & Consultants, our Dip Type Basket Washer (Basket Bubble Washer) is engineered for efficient, validated cleaning of baskets, trays, and small components widely used in pharmaceutical, food processing, chemical, and precision engineering industries. The washer uses an immersion-based cleaning process with pre-soak → bubble agitation → detergent wash → high-pressure rinse → optional sanitization → hot-air or air-knife drying, ensuring uniform cleaning of even hard-to-reach surfaces while conserving water and chemicals through recirculation and filtration.

The system combines air-bubble agitation, high-pressure spray manifolds, and cage rotation options to effectively remove powders, sticky residues, oils, process debris, and microbial contamination. Built with hygienic SS304/316L stainless steel, orbital welds, inline filtration, and automated chemical dosing, it ensures compliance with cGMP and food-grade hygiene standards. Optional modules include validation-ready documentation, ultrasonic cleaning, and heat recovery systems for enhanced efficiency and regulatory compliance.

Capable of handling 100–300 baskets per hour (depending on size and load), this washer is ideal for centralized cleaning in pharma cleanrooms, food plants, chemical laboratories, and component manufacturing units. With compliance to cGMP, US-FDA, WHO-GMP, and ISO hygiene regulations, the Dip Type Basket Washer supports reliable, repeatable cleaning results, reduced manual labor, and greater operational consistency for regulated industries.

The SS Engineers IBC Drum Washer (Rotary Nozzle – Under Standing Model) is designed for precision cleaning of Intermediate Bulk Containers (IBCs), large drums, and chemical barrels widely used in the pharmaceutical, food, beverage, and chemical process industries. The system employs a validated multi-stage cycle of pre-rinse → detergent wash → purified-water rinse → optional steam/hot-water sanitization → high-velocity air or hot-air drying, ensuring thorough residue removal and compliance with international hygiene standards.

Constructed in SS304/316L with orbital sanitary welds, the washer integrates rotary nozzles positioned underneath the standing drum/IBC, providing 360° spray coverage for effective removal of powders, APIs, solvents, sticky residues, oils, corrosive chemicals, and process by-products. Recipe-driven wash programs, automated chemical dosing, and inline filtration ensure consistent cleaning quality while minimizing water, detergent, and energy consumption.

With a throughput of 20–50 IBCs or drums per hour, the system is well-suited for centralized washing stations in pharma plants, chemical facilities, food industries, and logistics hubs. Optional modules include validated sanitization, IoT-enabled cycle monitoring, HEPA-filtered drying, and compliance-ready documentation to meet the stringent needs of regulated industries.

By combining robust construction, rotary under-nozzle spray technology, and automation-driven design, SS Engineers & Consultants’ IBC Drum Washer provides a reliable solution that enhances hygiene, reduces contamination risks, and ensures safe, repeatable cleaning cycles for reusable containers in critical industries.

The SS Engineers Inclined Conveyor is engineered for reliable and efficient material handling across a wide range of industries including food processing, pharmaceuticals, chemicals, packaging, and logistics. Designed to transport goods between different heights, it provides smooth, controlled movement of products such as bulk materials, packed items, raw ingredients, and containers with minimal spillage and maximum throughput.

Built with heavy-duty SS304/316 construction and food-grade belts or modular chain designs, the system integrates adjustable speed controls, load sensors, and optional cleated belts for enhanced grip. Hygienic sloped surfaces, easy-clean access panels, and sanitary welding ensure compliance with pharma and food-grade safety standards, making it suitable for high-care environments. Customization options allow it to handle powders, granules, boxes, pouches, and heavy-duty items with equal efficiency.

With a throughput capacity configurable to the production line, the Inclined Conveyor is ideal for upstream and downstream integration in automated plants. It can be combined with washers, fillers, packaging machines, or palletizers to create seamless process flows. Optional features include hopper feeding systems, magnetic belts for metal handling, and spill-containment designs to improve safety and productivity.

Fully compliant with HACCP, FSMS, ISO, and GMP standards, the SS Engineers Inclined Conveyor provides a robust and versatile solution for industries looking to improve ergonomics, reduce manual handling, and enhance operational efficiency.

The SS Engineers Steam Washer is purpose-built for effective, high-temperature cleaning and sanitization of containers, drums, parts, pallets, and accessories used across pharmaceutical, food, beverage, chemical, and industrial operations. By utilizing pressurized steam, the system ensures deep penetration cleaning, removal of oils, grease, residues, and complete microbial decontamination while significantly reducing chemical usage.

The cleaning process follows a proven sequence of steam pre-rinse → detergent wash (optional) → purified-water rinse → steam sanitization → hot-air or air-knife drying. Constructed entirely in SS304/316L with sanitary orbital welds, the washer features smooth, crevice-free surfaces, sloped drainage, and tool-free access for fast maintenance and hygiene assurance. Integrated steam jets, rotary spray nozzles, and oscillating manifolds provide 360° coverage for consistent results.

Available in manual, semi-automatic, and fully automated models, the Steam Washer can be configured with PLC/SCADA automation, recipe-driven wash programs, cycle logging, and validation-ready modules. Optional CIP integration, HEPA-filtered drying, and steam sterilization validation make it suitable for the strictest GMP-regulated environments.

Scalable from R&D labs to full-scale production facilities, the SS Engineers Steam Washer reduces manual labor, improves safety, and delivers repeatable, validated cleaning performance. Fully compliant with cGMP, WHO-GMP, US-FDA, HACCP, and FSMS standards, it offers industries a sustainable, high-efficiency solution for sterilization, hygiene assurance, and regulatory compliance.

The SS Engineers Tote Washer System is engineered for hygienic, automated cleaning of totes, bins, containers, and handling crates used in pharmaceutical, food, beverage, chemical, and logistics industries. These washers deliver enclosed, high-pressure cleaning with a validated cycle of pre-rinse → detergent wash → purified-water rinse → optional sanitizer → air-knife or hot-air drying, ensuring totes are residue-free, sanitized, and safe for reuse while conserving water and detergents through closed-loop recirculation and filtration.

Built from SS304/316L with sanitary welds, the systems include sloped drainage, smooth internal geometry, and tool-free access for easy cleaning and maintenance. Configurations are available in batch-type, conveyorized, and fully automated tote washer lines, equipped with rotary spray nozzles, oscillating manifolds, and programmable wash cycles. Optional CIP integration, HEPA-filtered drying, and steam sanitization make the system ideally suited for GMP-regulated and hygiene-critical environments. PLC/SCADA-based automation with sensors and VFDs ensures precision control, resource optimization, and operator safety.

Scalable from small-scale logistics hubs to high-capacity pharma, food, and chemical plants, the SS Engineers Tote Washer System reduces manual handling, enhances productivity, and ensures consistent throughput. Fully compliant with cGMP, WHO-GMP, US-FDA, HACCP, and FSMS standards, these systems deliver validated cleaning, regulatory compliance, and safe handling of reusable totes and bins across critical industries.