Categories

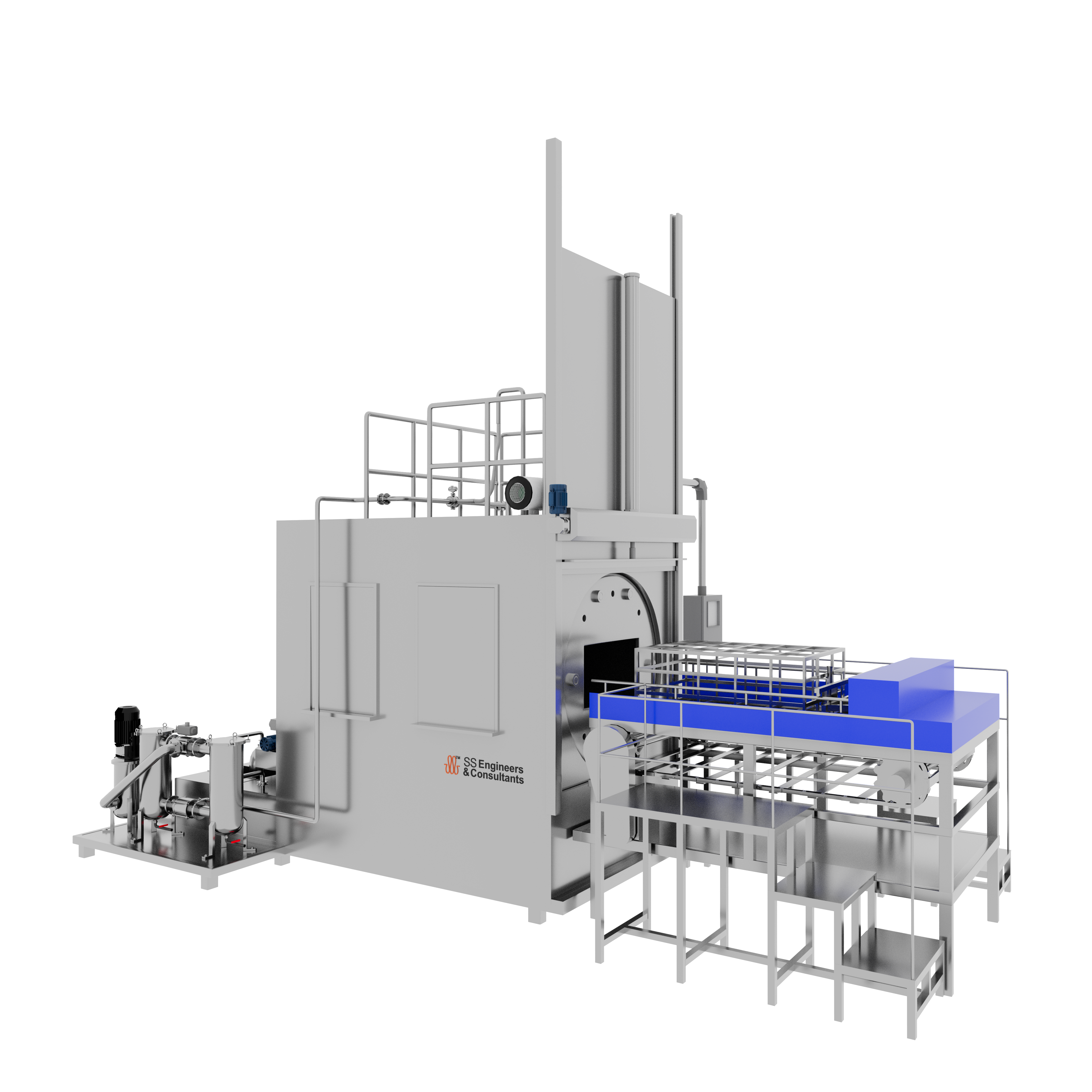

Cage Rotation Part Washer

SS Engineers & Consultants provide hygienic, high-throughput washing systems that are purpose-built

for custom applications, including specialized washers like cage rotation part washers, bakery crates,

trays, ingredient bins, and other industrial equipment. Engineered in SS304/316 with food-grade seals

and sanitary welds, our systems are designed to effectively remove contaminants such as flour dust,

dough residues, oils/fats, sugar syrups, allergens, and chocolate/coating carryover. The multi-zone

chambers (pre-wash, detergent wash, rinse, and optional hot-rinse/sanitize at 82–85 °C) ensure

high-impact spray patterns and adjustable conveyor speeds, delivering microbiologically safe results

while minimizing water, chemical, and energy consumption.

The key features of our systems include CIP-ready tanks with filtration, auto-dosing, inline temperature control, and easy-access maintenance doors. Hygienic sloped surfaces ensure full drainage, and PLC/SCADA automation offers precise recipe management for different SKUs, such as bread crates, bun trays, and confectionery bins. These systems are designed to provide maximum efficiency and consistent cleaning performance while maintaining the highest hygiene standards.

Optional features like air-knife blow-off reduce residual moisture, enabling faster turnaround to packaging or proofing areas. This makes our systems ideal for high-demand industries such as bakery production, where HACCP/FSMS compliance is critical. The integration of cutting-edge technology ensures that our washers meet the highest standards of cleanliness, operational efficiency, and regulatory compliance, making them the preferred choice for businesses in need of reliable, high-performance cleaning solutions.

The key features of our systems include CIP-ready tanks with filtration, auto-dosing, inline temperature control, and easy-access maintenance doors. Hygienic sloped surfaces ensure full drainage, and PLC/SCADA automation offers precise recipe management for different SKUs, such as bread crates, bun trays, and confectionery bins. These systems are designed to provide maximum efficiency and consistent cleaning performance while maintaining the highest hygiene standards.

Optional features like air-knife blow-off reduce residual moisture, enabling faster turnaround to packaging or proofing areas. This makes our systems ideal for high-demand industries such as bakery production, where HACCP/FSMS compliance is critical. The integration of cutting-edge technology ensures that our washers meet the highest standards of cleanliness, operational efficiency, and regulatory compliance, making them the preferred choice for businesses in need of reliable, high-performance cleaning solutions.

Key Features:

- SS304/316 hygienic construction with sanitary design and full-drain geometry

- Multi-zone cleaning with targeted spray manifolds for flour, oil/fat, and sugar residues

- Recipe-based programs for different crate/tray sizes and soil loads

- Hot rinse/sanitization (optional) to meet HACCP and food safety requirements

- Inline filtration, chemical auto-dosing, and water/heat recovery for lower OPEX

- PLC-based automation, conveyor speed control, and optional air-knife drying

See it in Action

Youtube Video Auto Playing without sound

Need Custom Solutions?

Our team can develop specialized cleaning solutions tailored to your bakery hygiene requirements.

Contact Our Experts