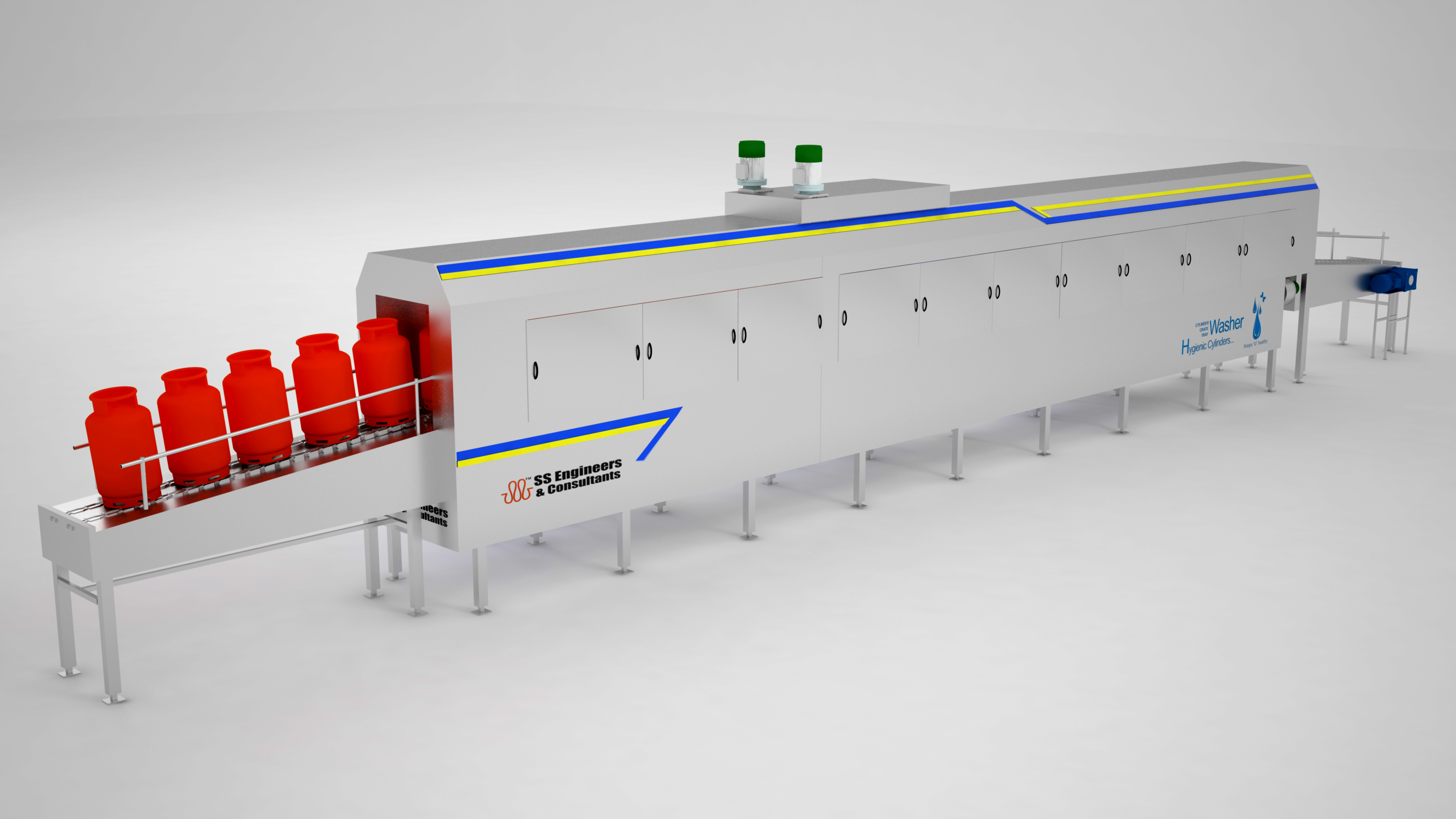

LPG Cylinders Degreasing machine

SS Engineers & Consultants’ LPG Cylinder Cleaning Machine is engineered for hygienic, high-throughput cleaning of LPG cylinders, widely used in the oil and gas industries, including companies like ONGC. The system automates the cleaning cycle with a continuous conveyor design, ensuring the efficient removal of stubborn residues, rust, oil deposits, and other contaminants while minimizing water and chemical use through recirculation and filtration.

The system follows a multi-stage process—pre-rinse → detergent wash → high-pressure final rinse → optional hot sanitization → air-knife drying—to ensure that cylinders are thoroughly sanitized and ready for reuse. High-impact spray nozzles, variable conveyor speeds, and recipe-based PLC controls allow the system to handle various cylinder sizes and contamination levels, ensuring consistent performance.

Built entirely in SS304/316 stainless steel, the LPG Cylinder Cleaning Machine is designed for durability, easy maintenance, and a long service life under continuous operation. The machine’s robust construction and user-friendly interface make it ideal for demanding environments, meeting the high operational standards required in the oil and gas industry.

The system is designed to process up to 300–500 cylinders per hour, with the option to scale with customized multi-lane conveyors. It is capable of meeting the stringent hygiene requirements of HACCP, FSMS, and GMP standards, ensuring that the cylinders are thoroughly cleaned and safe for refilling and distribution.

Optional features include steam or hot-water sanitization, inline filtration, automatic chemical dosing, and integration with cylinder unloading, stacking, and reloading conveyors, which contribute to end-to-end automation and increased efficiency in high-volume operations. These features ensure that the system operates with minimal downtime and maximizes throughput.

By integrating robust design, automation, and energy-efficient operation, SS Engineers & Consultants’ LPG Cylinder Cleaning Machine Conveyor helps the oil and gas industry, including ONGC, reduce manual labor, speed up turnaround times, and maintain consistent hygiene. This system ensures that LPG cylinders are clean, safe, and ready for use in every refill and distribution cycle, supporting optimal safety and operational efficiency in the industry.

Cylinder Halves degreasing machine

Our LPG Cylinder Halves Degreasing Machine is engineered for efficient cleaning and degreasing of cylinder halves used in oil and gas industry operations, particularly in the manufacturing, storage, and handling of LPG cylinders. The system effectively removes grease, oil residues, rust, and contaminants that accumulate during the production and maintenance processes, ensuring that cylinders are thoroughly prepared for further processing or refilling.

The system operates through a multi-stage process—pre-rinse → detergent wash → final rinse → optional hot sanitization → air drying—which ensures thorough cleaning while minimizing water and chemical consumption. The closed-loop filtration and recirculation system ensure efficient use of resources, providing consistent cleaning results with minimal environmental impact.

The machine is designed to handle high volumes with typical capacities of 300–500 cylinder halves/hour, and its capacity can be scaled with customized multi-lane conveyors. This makes it ideal for high-throughput operations at oil refineries, manufacturing plants, and distribution hubs, where efficiency and hygiene are critical.

PLC/SCADA automation enables operators to control the cleaning process with recipe-based programs tailored to different cylinder sizes and contamination levels. Real-time monitoring and cycle logging ensure that each cleaning cycle is thoroughly documented and traceable, providing full operational transparency.

Optional add-ons such as air-knife blow-off systems provide rapid drying of cylinder halves, while heat recovery units contribute to energy savings, making the system even more efficient. The inclusion of automated cylinder infeed/outfeed conveyors ensures seamless integration into existing production lines, automating the entire cleaning process and reducing the need for manual labor.

Built to meet HACCP, FSMS, and international hygiene standards, SS Engineers & Consultants’ LPG Cylinder Halves Degreasing Machine provides a reliable solution for oil and gas manufacturers. It helps reduce operational costs, extend cylinder lifespan, and maintain consistent hygiene across the supply chain, ensuring that each cylinder is clean, safe, and ready for use in the refilling or maintenance cycle.

The Conveyor System is engineered to provide efficient, high-throughput transportation of plastic crates, cans, and trays used in milk collection, dairy processing, and packaging operations. It ensures smooth and continuous movement of items, helping eliminate bottlenecks in the workflow while maintaining operational efficiency. The system follows a multi-stage process—pre-rinse → detergent wash → final rinse → optional hot sanitization → high-velocity air drying—delivering consistent results while conserving water and chemicals through recirculation and inline filtration.

Systems can be equipped with inline filtration, automatic chemical dosing, energy-efficient heating, and VFD-driven conveyors to reduce OPEX while maintaining strict hygiene standards. With a typical capacity of 300–500 crates/hour (scalable with multi-lane designs), it is ideal for centralized washing stations in dairies, cooperatives, and milk product plants. PLC/SCADA automation allows recipe-based programming for different crate or can sizes, with real-time monitoring and cycle logging.

Layouts can include integrated infeed/outfeed conveyors, stacking/destacking modules, and inspection points. Built entirely in SS304/316 with wash-down design and food-grade components, the conveyor system ensures long service life, easy sanitation, and compliance with international standards like HACCP, FSMS, and GMP.

By combining robust construction, automation, and hygienic design, SS Engineers & Consultants’ Conveyor System helps dairy processors reduce manual labor, maintain hygiene, extend crate life, and ensure smooth, safe, and efficient movement of crates throughout the milk collection and packaging cycle.