Categories

Cylinder Halves Degreasing Machine

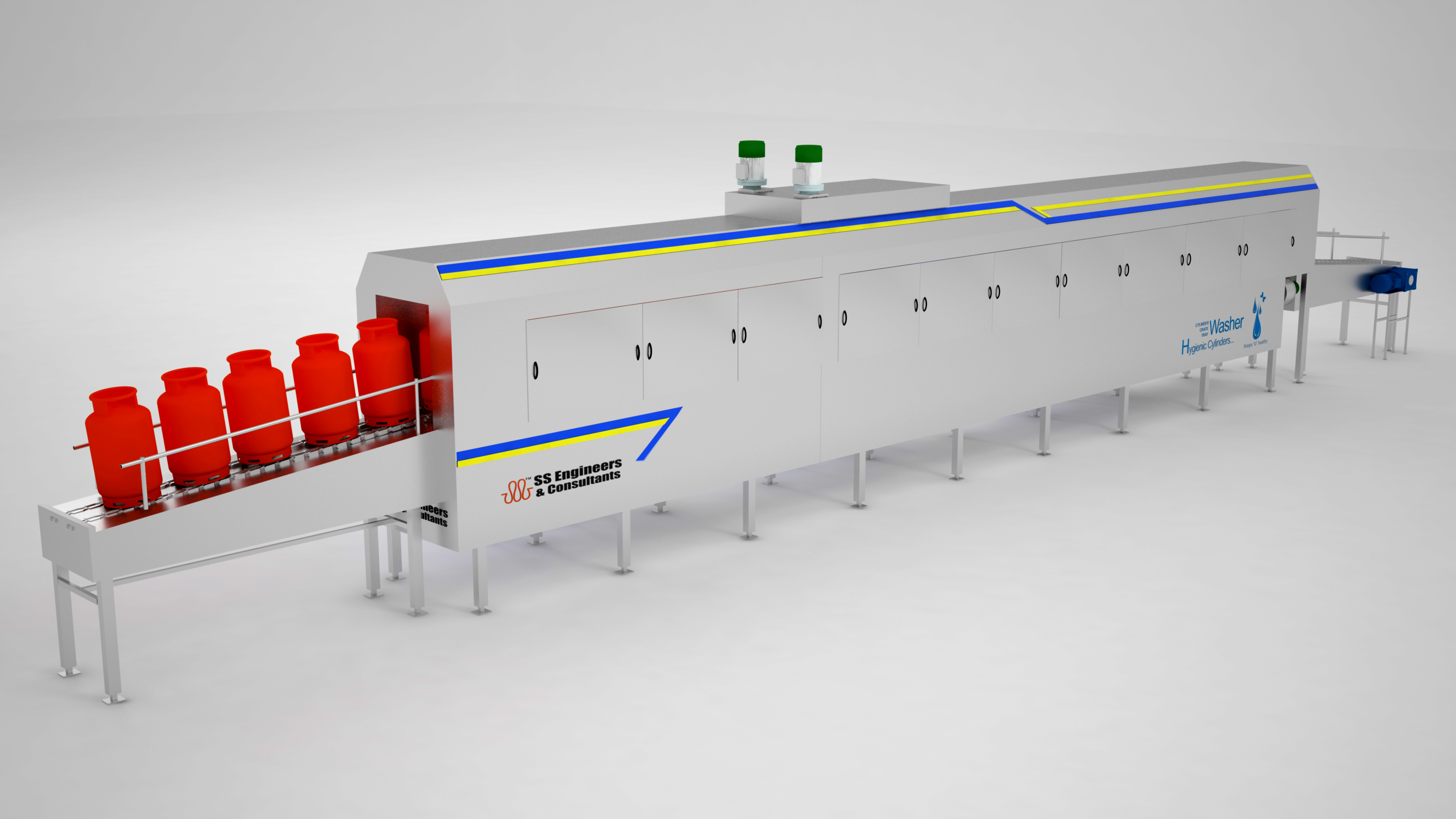

SS Engineers & Consultants offer high-performance degreasing systems specially designed for cleaning LPG

cylinder halves. Built with SS304/316 material and food-grade seals, these machines effectively remove

oils, greases, rust, and other contaminants from cylinder surfaces, ensuring a clean and safe surface

for further processing. Our systems are ideal for industrial use, providing a robust solution for

high-volume degreasing operations.

The machine operates with multi-zone chambers, including pre-wash, detergent wash, rinse, and an

optional hot-rinse/sanitize stage. These stages ensure that each cylinder half is thoroughly degreased,

with the process reaching optimal temperatures of 82–85°C. High-impact spray patterns and adjustable

conveyor speeds guarantee consistent results, making the system highly effective for cleaning and

degreasing large batches of cylinder halves.

The system includes CIP-ready tanks with filtration, auto-dosing for detergent and chemicals, and inline

temperature control for precise washing. Designed for ease of maintenance, it features easy-access

doors, hygienic sloped surfaces for complete drainage, and minimal manual intervention. The automation

capabilities, such as PLC/SCADA systems, allow for recipe management to accommodate different cylinder

sizes and models, enhancing operational efficiency.

Optional features like air-knife blow-off help eliminate residual moisture, improving turnaround times

and ensuring that cylinders are dry and ready for the next stage in processing. With compliance to

safety and cleanliness standards, this system optimizes productivity, reduces downtime, and meets

industry requirements for handling LPG cylinders in a hygienic, efficient manner.

Key Features:

- SS304/316 hygienic construction with sanitary design and full-drain geometry

- Multi-zone degreasing with targeted spray manifolds for oil, grease, rust, and other contaminants

- Recipe-based programs for different cylinder half sizes and varying contamination levels

- Hot rinse/sanitization (optional) to meet industry safety and hygiene standards

- Inline filtration, chemical auto-dosing, and water/heat recovery for reduced operational costs (OPEX)

- PLC-based automation, adjustable conveyor speed control, and optional air-knife blow-off for faster drying and optimal throughput

See it in Action

Youtube Video Auto Playing without sound

Need Custom Solutions?

Our team can develop specialized cleaning solutions tailored to your bakery hygiene requirements.

Contact Our Experts