Categories

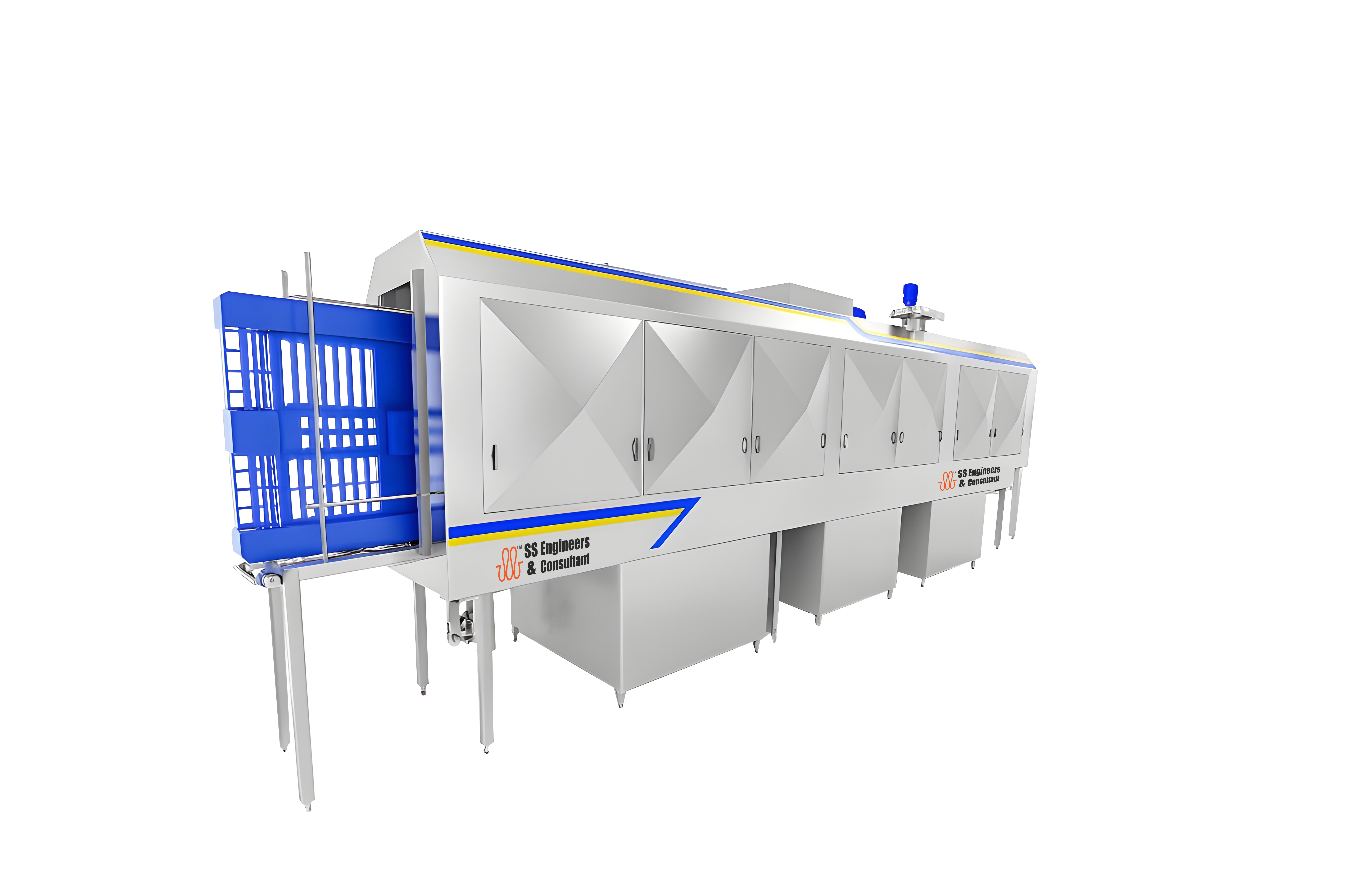

SS Engineers & Consultants design and supply advanced conveyor systems tailored for pharmaceutical and chemical industries. Built with SS304/316 construction and sanitary welds, our conveyor systems ensure safe, contamination-free material handling in controlled environments, from production to packaging.

Our solutions efficiently move crates, bins, and components, designed to handle varying sizes and weights while ensuring minimal contamination. High-performance conveyors are equipped with adjustable speeds and sturdy frames to accommodate diverse workloads, while reducing water, chemical, and energy consumption.

Engineered with robust features such as CIP-ready conveyors, inline filtration, automated controls, and real-time monitoring, our systems meet stringent hygiene standards. They offer seamless integration into production lines, with easy maintenance access, automated PLC/SCADA controls, and recipe management.

Optional features such as air-knife blow-off and hot-air drying modules enhance productivity by reducing turnaround times. Designed for GMP, FDA, and international safety compliance, SS Engineers' conveyor systems optimize material flow, enhance safety, and ensure operational efficiency in pharmaceutical and chemical industries.

- SS304/316 construction with sanitary design and sloped drainage for hygiene

- Efficient material handling for crates, bins, and pharma components

- Adjustable conveyor speeds and modular design for flexible load handling

- Optional hot rinse and sanitization for GMP, FDA, and international compliance

- Inline filtration, automated controls, and energy/water recirculation

- PLC/SCADA automation with easy integration and recipe management

- Optional air-knife and hot-air drying modules for faster processing

See it in Action

Need Custom Solutions?

Our team can develop specialized cleaning solutions tailored to your bakery hygiene requirements.

Contact Our Experts