Categories

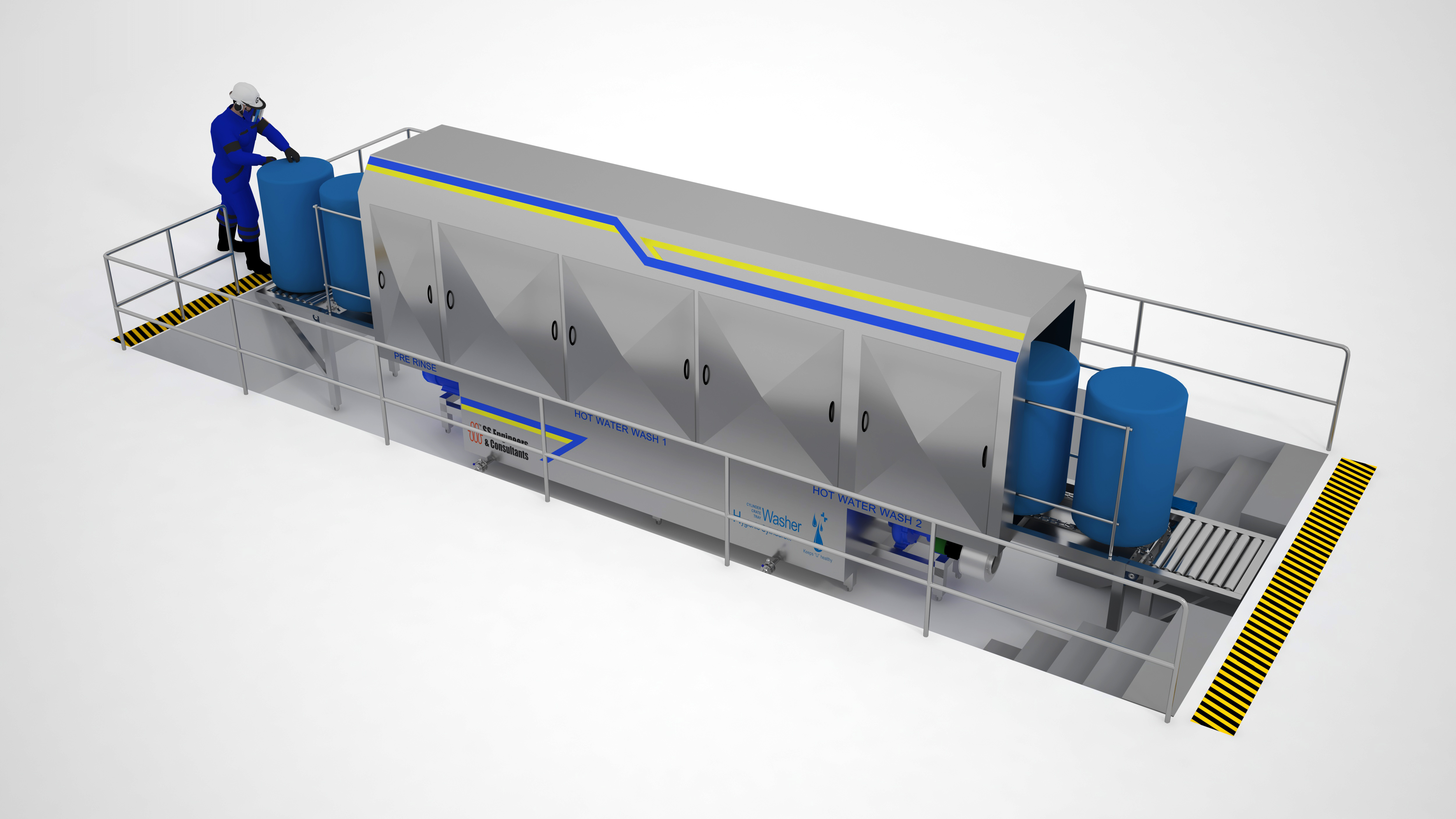

SS Engineers & Consultants design and supply advanced IBC washing systems purpose-built for pharmaceutical and chemical industries. Constructed in SS304/316 with GMP-grade seals and sanitary welds, our washers ensure contamination-free cleaning of intermediate bulk containers (IBCs) used for critical material handling.

These systems effectively remove solvents, APIs, chemical residues, powders, and hazardous contaminants through multi-zone chambers with pre-wash, detergent wash, rinse, and optional hot-rinse/sanitization at 82–85 °C. High-impact spray lances and adjustable wash programs deliver validated cleaning while reducing water, chemical, and energy consumption.

Engineered with CIP-ready tanks, inline filtration, automated chemical dosing, and real-time monitoring of temperature and conductivity, our IBC washers meet stringent hygiene and safety requirements. Easy-access maintenance doors, sloped drainage surfaces, and PLC/SCADA automation with recipe management make operation simple and reliable across different container SKUs.

Optional modules such as air-knife blow-off and hot-air drying reduce turnaround time, allowing faster reuse of containers in production and logistics. Designed for GMP, FDA, and international safety compliance, SS Engineers IBC washers safeguard product integrity, operator safety, and process efficiency in pharmaceutical and chemical facilities.

- SS304/316 GMP-grade construction with sanitary welds, smooth surfaces, and sloped drainage for hygiene

- Multi-zone IBC cleaning with high-impact spray lances for powders, solvents, and hazardous residues

- Recipe-driven wash cycles adaptable for different IBC sizes, shapes, and contamination levels

- Optional hot rinse/sanitization (82–85 °C) for validated cleaning and global compliance

- CIP-ready tanks with inline filtration, automated chemical dosing, and water/heat recirculation for efficiency

- PLC/SCADA automation with container handling options, recipe management, and optional air-knife/hot-air drying

See it in Action

Need Custom Solutions?

Our team can develop specialized cleaning solutions tailored to your bakery hygiene requirements.

Contact Our Experts