Categories

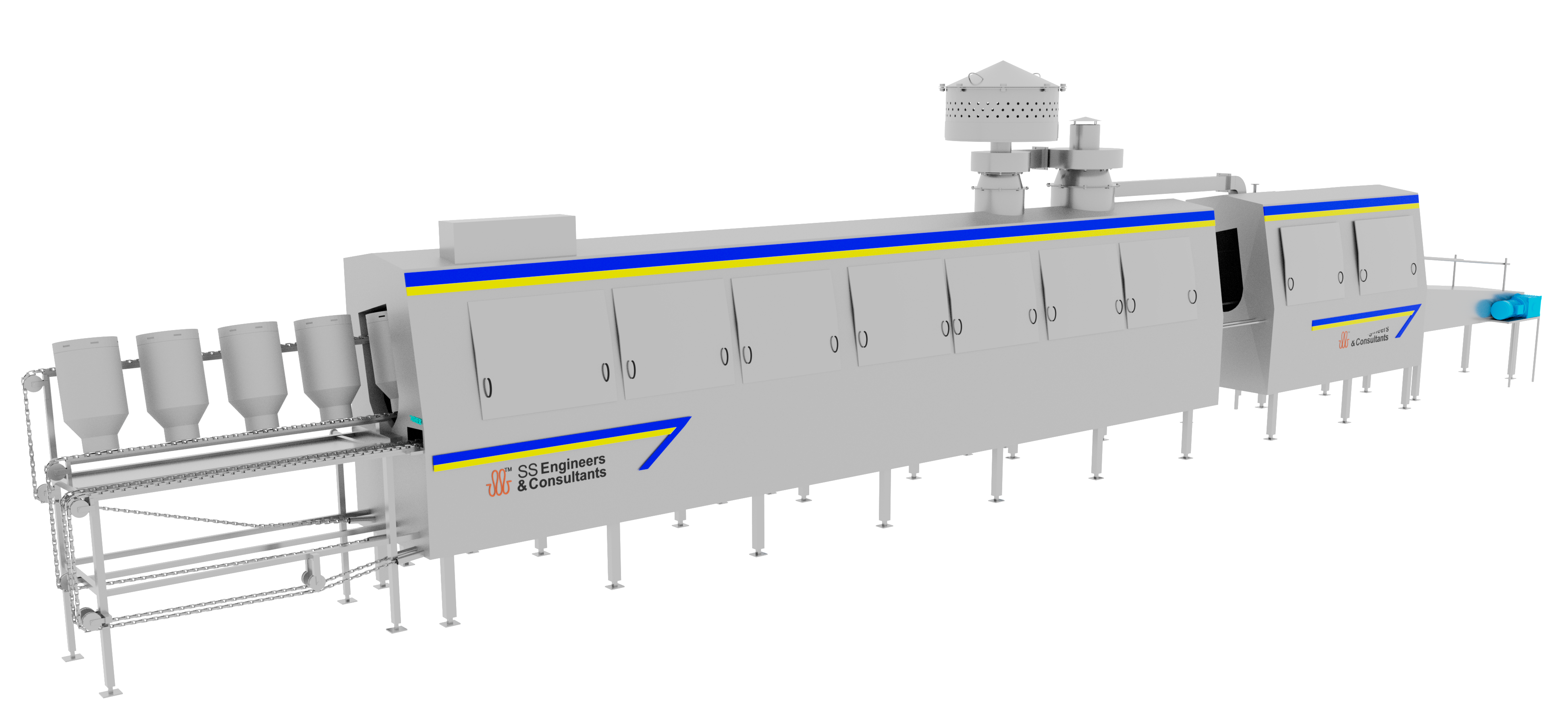

SS Engineers & Consultants’ Milk & Dairy Crate Washer is a hygienic, high-throughput system purpose-built for plastic crates, trays, and tote bins used across milk collection, processing, and packaging. Manufactured in SS304/316 with food-grade seals and sanitary welds, it reliably removes milk residues, butterfat, whey solids, protein films, and lactose/sugar deposits to safeguard product quality and compliance.

The washer employs a multi-zone process—pre-rinse → alkaline/detergent wash → final rinse → optional hot-rinse/steam sanitization at 82–85 °C—with high-impact spray manifolds and adjustable conveyor speed for different crate formats. Closed-loop filtration and recirculation minimize water, chemical, and energy consumption while delivering consistent, microbiologically safe results.

Core features include CIP-ready tanks with filtration, automatic chemical dosing, inline temperature control, post-wash drip/dwell zones for complete drainage, easy-access maintenance doors, and hygienic sloped surfaces for full runoff. PLC/SCADA automation with recipe management supports multiple crate/tray sizes and provides audit-friendly cycle logging.

As part of the SS Engineers ecosystem, the Crate Washer integrates seamlessly with our conveyor systems, milk can washers, and packing lines for end-to-end dairy hygiene. Optional air-knife blow-off, heat-recovery, and conductivity/TDS-based dosing controls further reduce OPEX and turnaround time. The design complies with HACCP, FSMS, and GMP standards and is backed by our application engineering, commissioning, and after-sales support.

- SS304/316 hygienic construction with sanitary welds, wash-down design, and full-drain geometry

- Multi-zone cleaning: pre-rinse → alkaline/detergent wash → final rinse → optional hot-rinse/steam sanitization (82–85 °C)

- Continuous conveyor with crate carriers/guides, auto-singulation/aligners, and synchronized infeed/outfeed to upstream washers/fillers/packers

- High-impact spray manifolds with adjustable angles for thorough side/edge cleaning; post-wash drip/dwell zones improve drainage and drying

- Recipe-based PLC/SCADA programs for multiple crate/tray formats with VFD conveyor speed control, jam/queue detection, and batch/cycle logging

- Inline filtration, conductivity/TDS-based chemical auto-dosing, water/heat recovery, and optional air-knife blow-off for lower OPEX and rapid turnaround