Categories

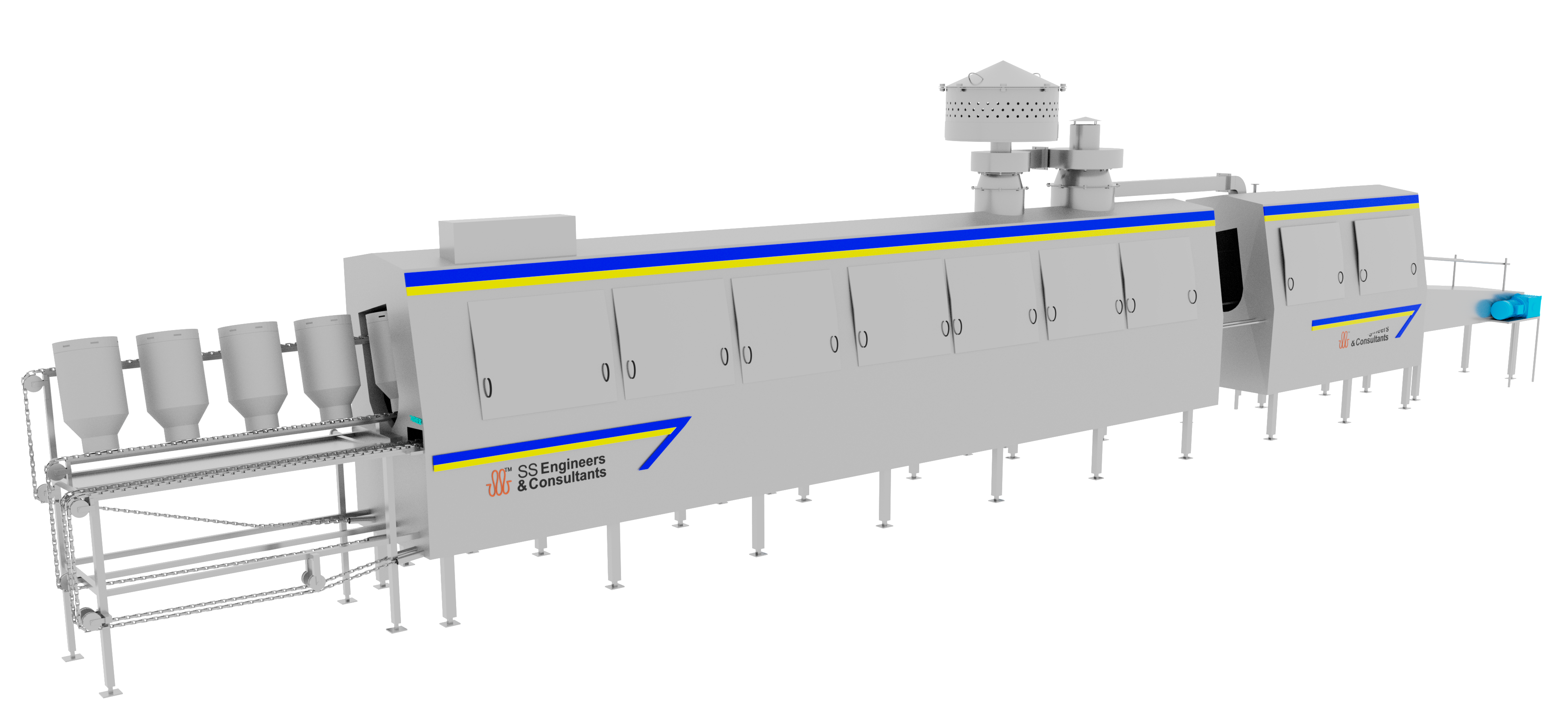

SS Engineers & Consultants’ Ice Cream Conveyor System provides hygienic, high-throughput material handling for crates, trays, cups, and tubs across ice cream and dairy plants. Built in SS304/316 with wash-down design and sanitary welds, it maintains product integrity from mix preparation and filling to hardening/spiral tunnels, wrapping, cold storage, and dispatch—while preserving the cold chain and minimizing manual handling.

Configurable as straight, Z-elevator, curved, roller, and accumulation/buffer sections, the line uses VFD-driven motors with PLC/SCADA orchestration and recipe logic to synchronize with fillers, metal detectors, checkweighers, and packers. Low-temperature duty components, anti-condensation provisions, and gentle-transfer geometry protect delicate products such as bars, cones, family tubs, and novelty SKUs.

Features include quick-release modular belts, UHMWPE wear strips, tool-less tensioning, drip pans for post-wash carryover, IP65/66 enclosures, and sealed bearings for chilled rooms. Smart options—counting/singulation, merge/diverter modules, barcode/QR/RFID tracking, and vision-based QA—enable precise flow control. The system interfaces cleanly with crate washers for inbound packaging hygiene and with case/tote handling used in dairy logistics.

As part of the SS Engineers ecosystem, the Ice Cream Conveyor System integrates seamlessly with our Crate Washers, Milk Can Washers, and packing lines to deliver end-to-end dairy hygiene and traceability. Compliant with HACCP, FSMS, and GMP, it helps processors boost throughput, cut OPEX, and maintain consistent quality from production to frozen distribution.

- SS304/316 hygienic construction with sanitary welds, wash-down design, and full-drain geometry

- Continuous conveyor with crate carriers/guides, auto-singulation, and synchronized infeed/outfeed to ice-cream/dairy fillers, hardening tunnels, and packers; cold-chain-ready, anti-condensation components

- Multi-zone cleaning: pre-rinse → alkaline/detergent wash → final rinse → optional hot-rinse/steam sanitization (82–85 °C)

- High-impact spray manifolds with angled edge/corner jets and de-sugaring patterns to remove cream/fat, syrup, chocolate, and coating residues; drip/dwell zones for complete drainage and faster drying

- Recipe-based PLC/SCADA programs for dairy crate/tray formats (cups, cones, bars, tub logistics) with VFD conveyor speed control, jam/queue detection, and batch/cycle logging for traceability

- Inline filtration, conductivity/TDS-based chemical auto-dosing, water/heat recovery, and optional air-knife blow-off to lower OPEX and speed turnaround in ice-cream & dairy operations