Categories

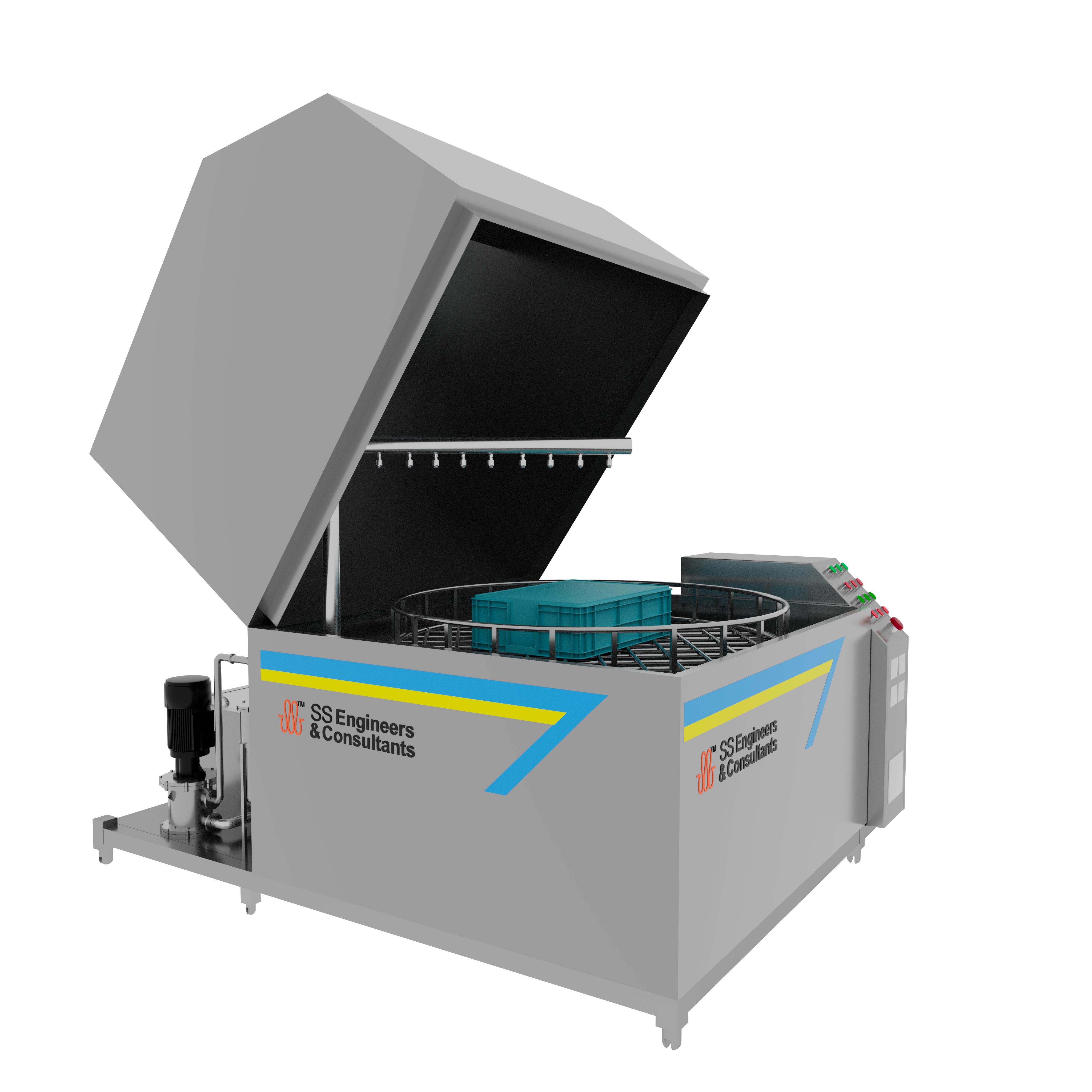

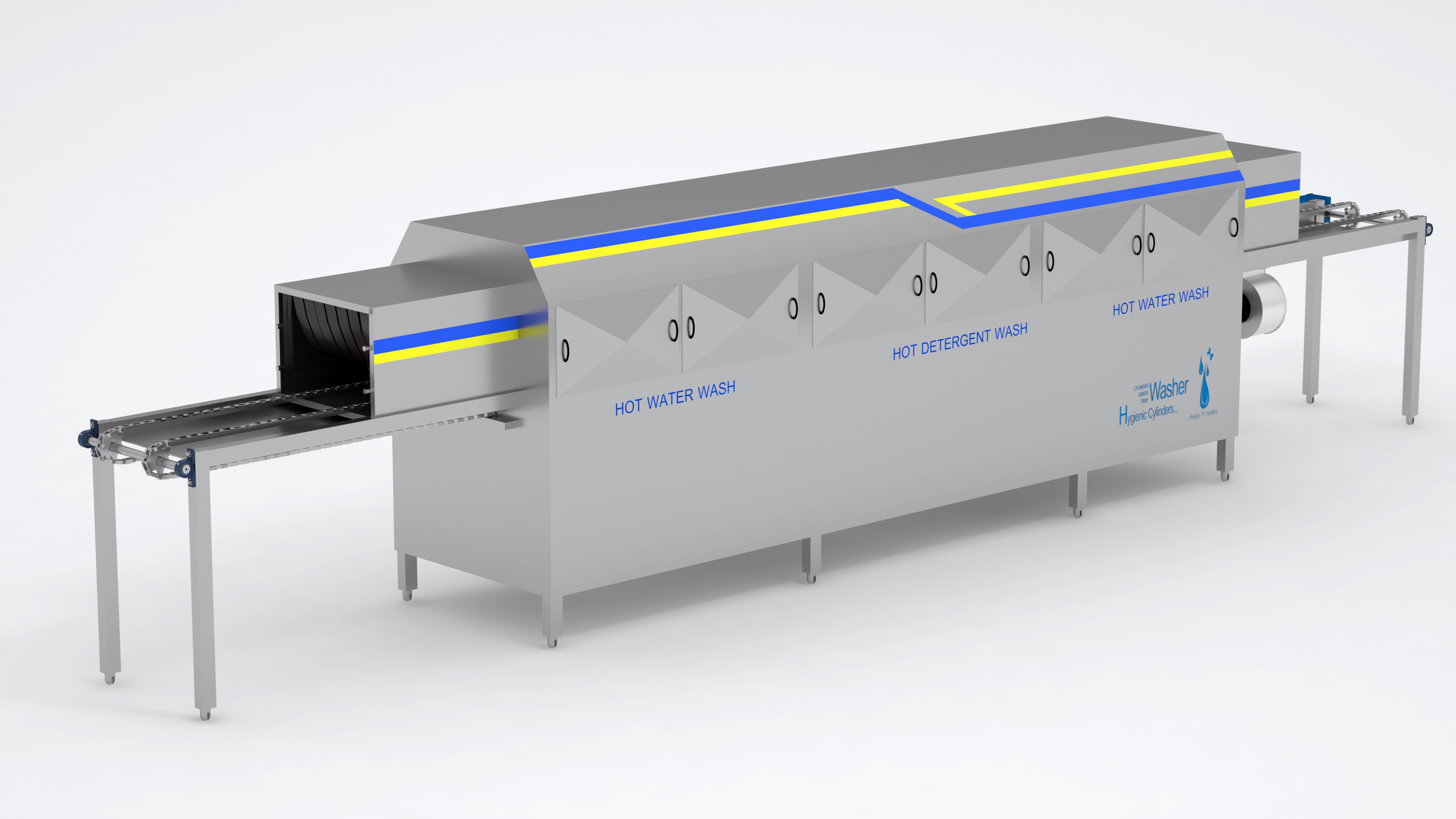

Crate Washer

SS Engineers & Consultants offer advanced, professional-grade washing systems designed for automobile storage

bins, trays, and crates. Our crate washers are engineered with precision using SS304/316 construction, ensuring

maximum hygiene, corrosion resistance, and long operational life. Equipped with high-pressure spray nozzles,

multi-zone washing chambers, and adjustable conveyor speed, these machines effectively remove oil stains,

grease, carbon deposits, and automotive residues.

Integrated CIP (Clean-In-Place) systems reduce downtime and minimize water and chemical consumption, while

energy-efficient pumps and blowers ensure optimized performance. The design also incorporates easy-access

maintenance panels, ergonomic loading/unloading, and PLC-based automation for seamless operation. With decades

of expertise, SS Engineers delivers robust, customizable washing solutions that align with international

automotive hygiene standards, making them the preferred choice for high-volume crate and bin cleaning

applications.

Key Features:

- High-performance stainless-steel construction for durability and corrosion resistance

- Customizable cleaning programs for different automotive components

- Effectively eliminates oil, grease, and industrial contaminants

- Optimized for hygiene compliance in manufacturing environments

- Compatible with various container materials including plastic and metal

- Reduces downtime and enhances container reuse efficiency

See it in Action

Youtube Video Auto Playing without sound

Specifications — Crate Washer

Separate tables for each model family. Tables can expand/collapse; only horizontal scrolling is used when needed.

Fixed Tank — 1, 2 & 3 Zone Models

| Parameter | 1-Zone | 2-Zone | 3-Zone |

|---|---|---|---|

| Capacity | 200–300 crates/hour | 400–600 crates/hour | 800–1000 crates/hour |

| Crate Size (typ.) | 600 × 400 × 330 mm | 600 × 400 × 330 mm | 600 × 400 × 330 mm |

| Configuration | Straight, single track/chain | Straight, single track/chain | Straight, single track/chain |

| Washing Sequence | Hot water / solvent rinse | Hot detergent → Hot water rinse | Hot water → Hot detergent → Hot water rinse |

| Nozzle Pressure (rinse) | — | 3.5–5.0 kg/cm² | 3.5–5.0 kg/cm² |

| Nozzle Pressure (detergent) | 3.5–4.5 kg/cm² | 3.5–4.5 kg/cm² | 3.5–4.5 kg/cm² |

| Rinse Water Temp. | 60–70 °C | 55–60 °C | 55–60 °C |

| Detergent Temp. | — | 60–70 °C | 60–70 °C |

| Electric Power (drives+pumps) | ~9–10 HP | ~16–17 HP | 24.5–25.5 HP |

| Heaters (water) | 30 kW (3×10) | 60 kW (6×10) | 90 kW (9×10) |

| Finish | SS polished to 150-grit | SS polished to 150-grit | SS polished to 150-grit |

| Temperature Control | Hot water / solvent | Detergent & rinse | Detergent & rinse |

| Main Enclosure | SS304, 2 mm | SS304, 2 mm | SS304, 2 mm |

| Under Frame | SS304, 50×50×2 mm | SS304, 50×50×2 mm | SS304, 50×50×2 mm |

| Conveyor Chain | SS link chain; drive & tensioner | SS link chain; drive & tensioner | SS link chain; drive & tensioner |

| Valves | SS ball valves | SS ball valves | SS ball valves |

| Filtration | All zones filtered | All zones filtered | All zones filtered |

| Sump Tanks | 1 × SS304 | 2 × SS304 | 3 × SS304 |

| Pumps | 1 set (Kirloskar/CNP equiv.) | 2 sets (Kirloskar/CNP equiv.) | 3 sets (Kirloskar/CNP equiv.) |

| Jet Nozzles | SS flat spray, fixed | SS flat spray, fixed | SS flat spray, fixed |

| Instrumentation | Pressure gauges; digital temp displays | Pressure gauges; digital temp displays | Pressure gauges; digital temp displays |

| Electrical Panel | SS304G; ON/OFF; indicators; E-stop | SS304G; ON/OFF; indicators; E-stop | SS304G; ON/OFF; indicators; E-stop |

| Wiring | ISI copper cables | ISI copper cables | ISI copper cables |

* Values may vary with options (air-knife / hot-air) and crate geometry.

Separate Tank — 2-Zone

| Parameter | Specification |

|---|---|

| Capacity | 100–400 crates/trays per hour (VFD controlled) |

| Crate/Tray Size (typ.) | 650 × 450 × 315 mm (confirm per project) |

| Machine Type | Separate-tank; tanks beneath zones with filter screen |

| Filtration | 2 mm perforated screens between wash zone & tanks; removable |

| Conveyor | Straight, single track chain conveyor |

| Drive | 2 HP, 1440 rpm motor with 50:1 hollow-shaft gearbox |

| Washing Sequence | Pre-rinse → Hot detergent → Hot water rinse |

| Nozzle Pressure | Pre-rinse 3.0–4.0 kg/cm²; det./final 4.0–5.0 kg/cm² |

| Water Temperatures | Det./rinse 60–70 °C; final 55–65 °C |

| Electric Power (pumps+drive) | ~17 HP @ 415 V, 3-ph, 50 Hz |

| Heaters (water) | 6 × 10 kW across two tanks |

| Pumps | 2 mono/multi-stage (CNP/Kirloskar: SS impeller, CI body, SS shaft, mech. seal) |

| Water Tanks | Below zones; filtered return via screen |

Optional Features (2-Zone)

- Oil skimmer (SS304 disc type)

- Automatic detergent dosing with pH control

- Air-knife section or hot-air drying extension

- Water quality monitoring (per tank)

- Retractable hose reel (SS304, 15 m)

- Fumes exhaust blower

- Relay logic or PLC-HMI control

Separate Tank — 3-Zone

| Parameter | Specification |

|---|---|

| Capacity | 500–800 crates/trays per hour (VFD controlled) |

| Crate/Tray Size (typ.) | 650 × 450 × 315 mm (confirm per project) |

| Machine Type | Separate-tank; tanks beneath zones with filter screen |

| Filtration | 2 mm perforated screens; removable for cleaning |

| Conveyor | Straight, single track chain conveyor |

| Drive | 2/3 HP, 1440 rpm motor with 50:1 hollow-shaft gearbox |

| Washing Sequence | Pre-rinse → Hot detergent → Hot water rinse → Final hot water |

| Nozzle Pressure | Pre-rinse 3.0–4.0 kg/cm²; det./final 4.0–5.0 kg/cm² |

| Water Temperatures | Det./rinse 60–70 °C; final 55–65 °C |

| Electric Power (pumps+drive) | 24.5–25.5 HP @ 415 V, 3-ph, 50 Hz |

| Heaters (water) | 9 × 10 kW across three tanks |

| Pumps | 3 mono/multi-stage (CNP/Kirloskar: SS impeller, CI body, SS shaft, mech. seal) |

| Water Tanks | Below zones; filtered return via screen |

Optional Features (3-Zone)

- Oil skimmer (SS304 disc type)

- Automatic detergent dosing with pH control

- Air-knife section or hot-air drying zone

- Water quality monitoring (per tank)

- PLC-HMI with data logging

- Retractable hose reel (SS304, 15 m)

- Fumes exhaust blower

Need Custom Solutions?

Our team can develop specialized cleaning solutions tailored to your specific automotive cleaning requirements.

Contact Our Experts