Categories

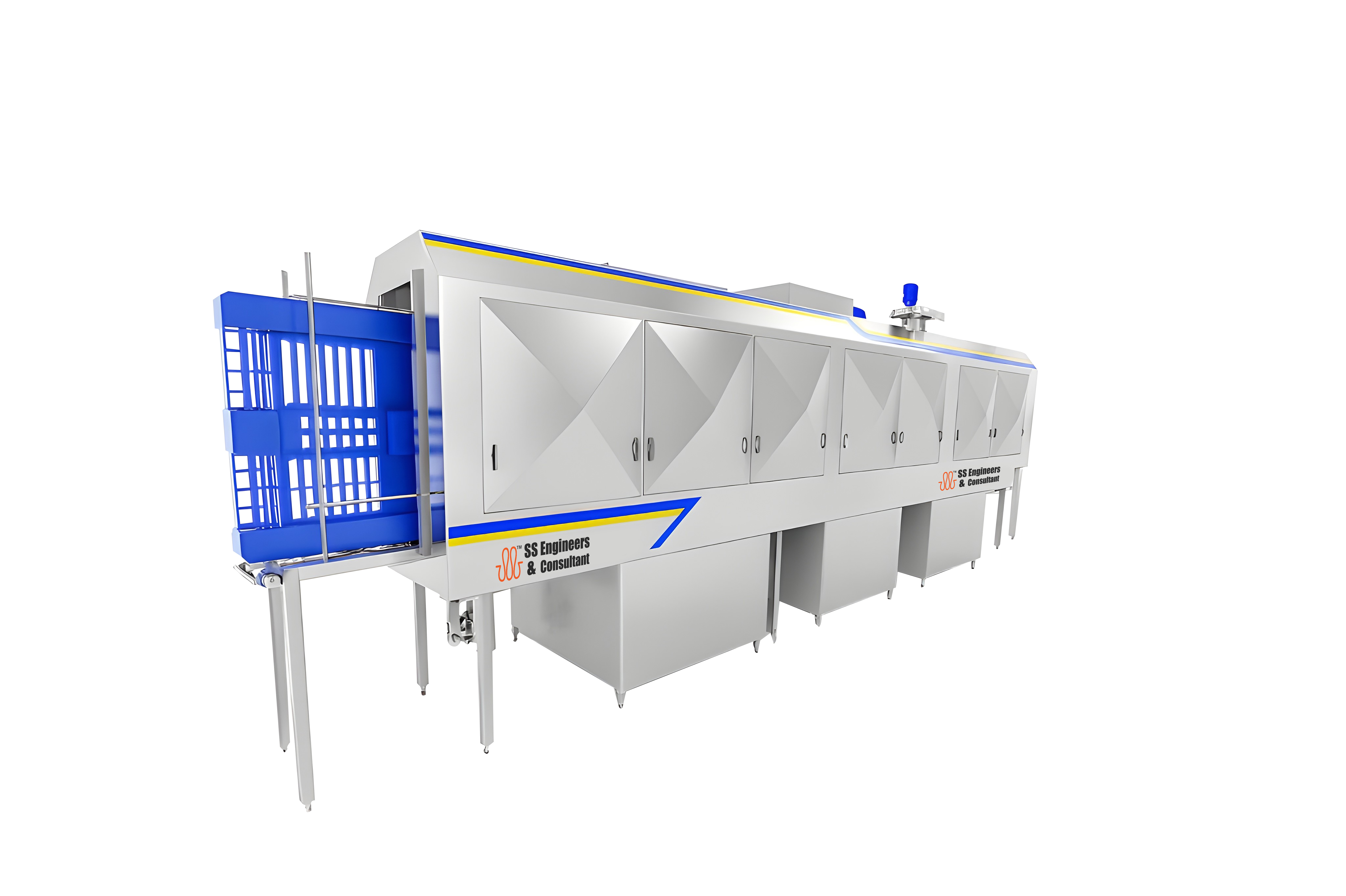

Rotary Table Batch Washer

SS Engineers & Consultants offer advanced Rotary Table Batch Washer systems designed for efficient and

controlled cleaning of components in batch operations. Constructed in robust SS304/316 stainless steel, these

machines deliver long-term durability, superior hygiene, and resistance to corrosion in demanding industrial

conditions. The rotary table mechanism allows components to be washed in fixed batches with precision spray

nozzles and high-pressure jets, ensuring consistent removal of oil, grease, dust, paint, and production

residues.

Multi-stage washing, filtration, and recirculation systems reduce water and chemical consumption while

maintaining cleaning efficiency. Energy-efficient pumps, ergonomic loading/unloading arrangements, and safety

interlocks make operation smooth and reliable. PLC-based automation with customizable programs enables flexible

cleaning cycles for varied parts and industries. SS Engineers’ Rotary Table Batch Washers provide unmatched

reliability and hygiene, setting high standards for productivity in automotive, engineering, and food-grade

cleaning applications.

Key Features:

- Robust SS304/316 stainless-steel construction, ensuring durability and resistance to corrosion

- Rotary table design enables efficient batch cleaning of multiple components at once

- High-pressure spray nozzles deliver thorough removal of oil, grease, dust, paint, and residues

- Flexible wash cycles and adjustable parameters to suit diverse cleaning requirements

- Integrated filtration and water recirculation system for reduced water and chemical consumption

- PLC-based automation with easy-to-use controls for consistent and reliable operation

- Adaptable for automotive, engineering, and food industry components in varied sizes

- Improves productivity by reducing manual handling, cleaning time, and operational downtime

See it in Action

Youtube Video Auto Playing without sound