Categories

Pallet Washer

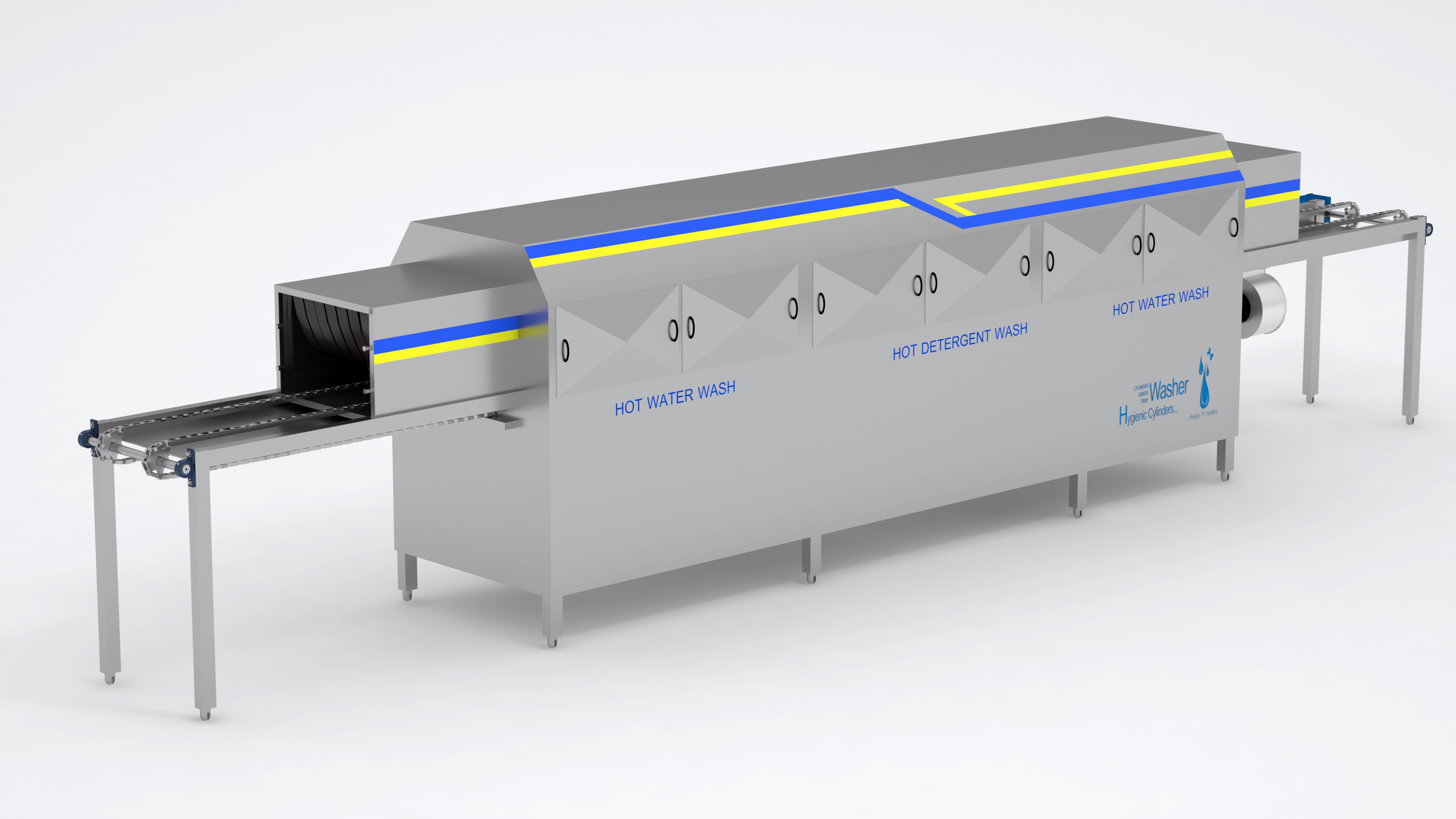

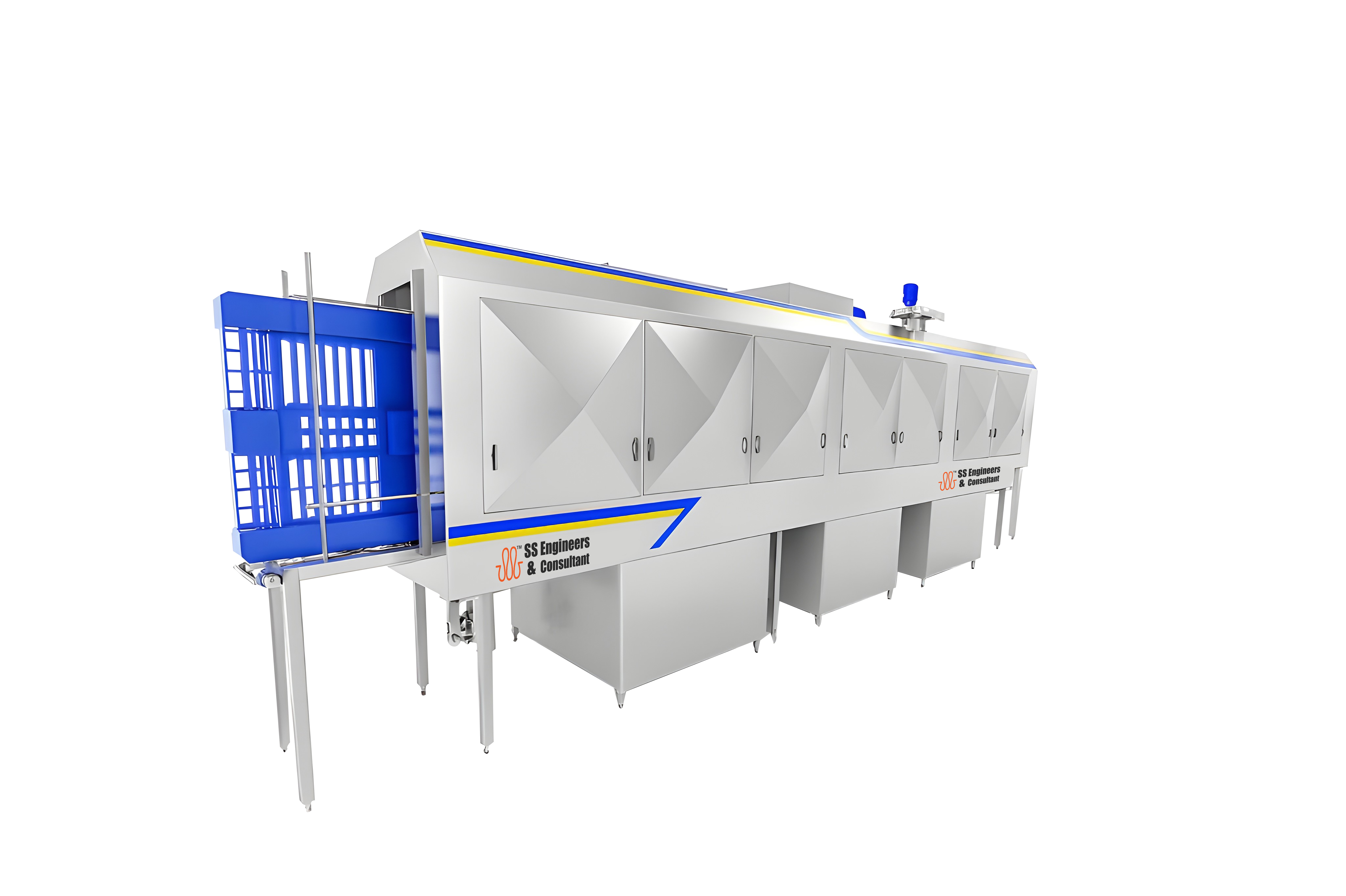

SS Engineers & Consultants provide advanced Pallet Washers engineered for efficient and hygienic cleaning of

pallets used across diverse industries. Constructed with robust SS304/316 stainless steel and high-quality

components, these systems deliver long service life, superior hygiene, and resistance to corrosion even in

demanding operations.

The washer design ensures thorough cleaning through high-pressure sprays, precision-controlled water flow, and

integrated filtration systems, supporting applications in food, pharmaceutical, and logistics sectors.

Automated wash cycles, adjustable parameters, and safety features optimize cleaning efficiency while minimizing

manual effort and downtime. Energy-efficient pumps, ergonomic layouts, and modular construction allow easy

installation, maintenance, and scalability. PLC-based controls with customizable programs offer flexible

operation tailored to varied pallet-cleaning requirements. SS Engineers’ Pallet Washers set new benchmarks in

hygiene and efficiency, ensuring consistent performance, product safety, and higher productivity in industrial

operations.

Key Features:

- Durable SS304/316 stainless-steel construction ensures long service life and superior resistance to corrosion

- High-pressure spray nozzles provide thorough cleaning and removal of dirt, grease, and residues

- Capable of handling pallets of various sizes with consistent cleaning quality

- Adjustable wash cycles and customizable configurations to meet diverse industry requirements

- Integrated filtration and water recirculation system reduces water and chemical consumption

- PLC-based automation with user-friendly controls for reliable and efficient operation

- Suitable for industries such as food processing, pharmaceuticals, logistics, and packaging

- Improves hygiene standards, reduces manual labor, and enhances overall productivity

See it in Action

Youtube Video Auto Playing without sound

Specifications — Pallet Washer

Comparative specs for 1-Zone, 2-Zone, and 3-Zone models. Toggle to view the complete table. Data sourced from SS Engineers & Consultants pallet washer proposal.

Fixed Tank — 1, 2 & 3 Zone Models

| Parameter | 1-Zone | 2-Zone | 3-Zone |

|---|---|---|---|

| Capacity (Pallets per Hour) | 10–15 PPH | 30–40 PPH | 50–100 PPH |

| Pallet Orientation | Horizontal / Vertical | Horizontal / Vertical | Horizontal / Vertical |

| Washing Zones / Stages | 1 Zone (Hot Water Wash) | 2 Zones (Hot Detergent + Final Hot Water Wash) | 3 Zones (Hot Water, Hot Detergent, Final Hot Water Wash) |

| Machine Dimensions (L × W × H) | 3.4 m × 1.6 m × 2.4 m | 5.5 m × 1.8 m × 1.5 m | 8.0 m × 1.8 m × 1.5 m |

| Pallet Dimensions Supported | 1200 × 1100 × 160 mm | 1200 × 1100 × 160 mm | 1200 × 1100 × 160 mm |

| Water Heating Method | Electrical Heaters (30 kW) | Electrical Heaters (60 kW) | Electrical Heaters (90 kW) |

| Steam Heating Facility | Available on request | Available on request | Available on request |

| Spray Jet Pumps | 9 kW | 16.5 kW | 27.6 kW |

| Air Knife System (Optional) | 2 × 7.5 HP Blowers | 2 × 7.5 HP Blowers | 2 × 7.5 HP Blowers |

| Conveyor System | SS 304G Honeycomb Belt + VFD | SS 304G Honeycomb Belt + VFD | SS 304G Honeycomb Belt + VFD |

| Control Panel | RLC or PLC-Based | RLC or PLC-Based | RLC or PLC-Based |

| Water Consumption (per 4–6 hrs) | 600–700 L | 1200–1400 L | 1800–2100 L |

| Total Connected Load (with heaters) | 39 kW (9 + 30) | 76.5 kW (16.5 + 60) | 117.6 kW (27.6 + 90) |

| Steam Consumption (if steam heated) | 90–100 kg/hr | 180–190 kg/hr | 250–280 kg/hr |

| Pallet Handling (Loading/Unloading) | Manual | Manual | Manual |

| Stacker / De-stacker | Available for horizontal orientation model only | Available for horizontal orientation model only | Available for horizontal orientation model only |

* Specs as per proposal; values may vary with selected options (e.g., air-knife, steam heating).