Categories

Conveyor System

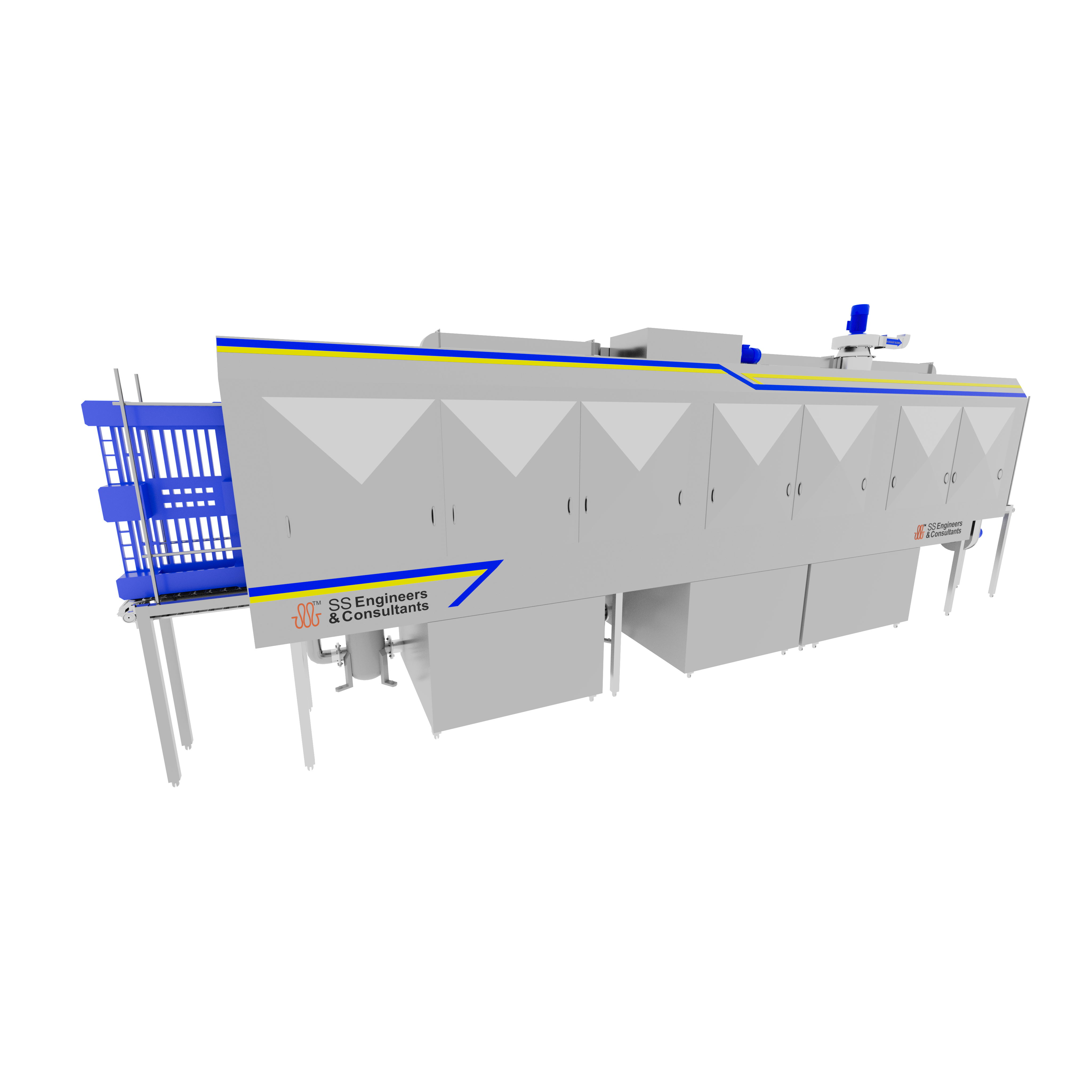

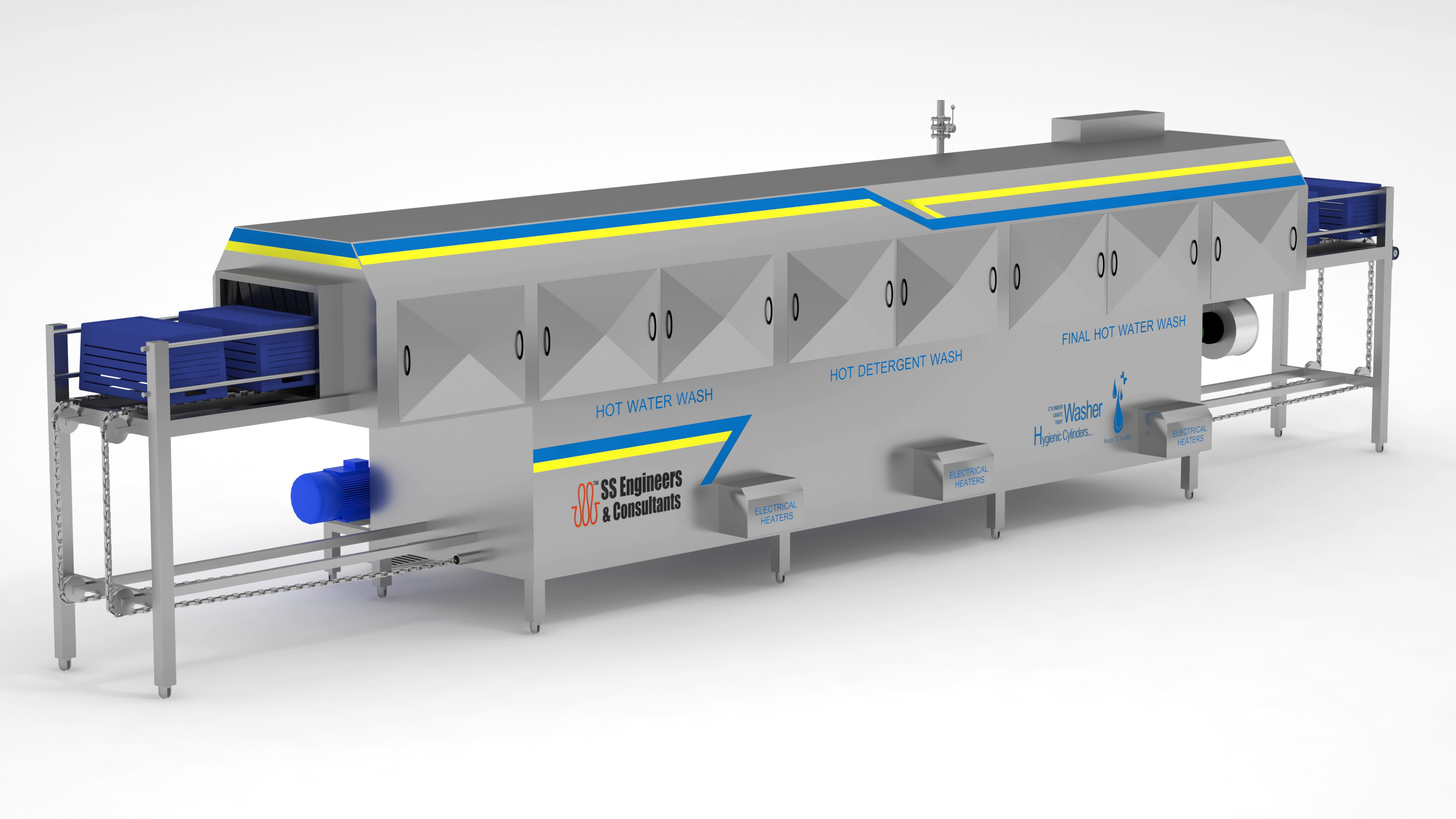

SS Engineers & Consultants provide hygienic, high-throughput conveyor systems

purpose-built for meat crates, poultry trays, hatchery baskets, food containers, and processing

equipment

widely used in slaughterhouses, hatcheries, poultry farms, cold-chain logistics, and large-scale

food processing plants.

Engineered in SS304/316 with food-grade belts and sanitary welds, our conveyors

streamline movement of

products, packaging, and wash-return items, ensuring safe, efficient, and hygienic material flow.

Configurations include straight belt, incline, Z-elevator, curve, accumulation, roller, and crate return conveyors designed for seamless integration from washing to processing, chilling, packing, and storage. Gentle handling systems with adjustable speeds minimize product damage while increasing operational efficiency.

Features include CIP-ready designs, inline inspection stations, automated diverters, and tray/crate return systems. Optional integrations such as offal removal belts, egg-tray conveyors, and pathogen-control modules provide tailored solutions for protein industry applications. Smooth surfaces, sloped drainage, and tool-less access ensure hygiene and easy maintenance.

Fully integrated PLC/SCADA automation with VFDs and smart sensors enables recipe-driven control, variable speed adjustment, and real-time monitoring. Supporting HACCP, FSMS, and international food safety standards, the SS Engineers Conveyor System delivers a reliable, efficient, and scalable backbone for modern poultry, meat, hatchery, and food service operations.

Configurations include straight belt, incline, Z-elevator, curve, accumulation, roller, and crate return conveyors designed for seamless integration from washing to processing, chilling, packing, and storage. Gentle handling systems with adjustable speeds minimize product damage while increasing operational efficiency.

Features include CIP-ready designs, inline inspection stations, automated diverters, and tray/crate return systems. Optional integrations such as offal removal belts, egg-tray conveyors, and pathogen-control modules provide tailored solutions for protein industry applications. Smooth surfaces, sloped drainage, and tool-less access ensure hygiene and easy maintenance.

Fully integrated PLC/SCADA automation with VFDs and smart sensors enables recipe-driven control, variable speed adjustment, and real-time monitoring. Supporting HACCP, FSMS, and international food safety standards, the SS Engineers Conveyor System delivers a reliable, efficient, and scalable backbone for modern poultry, meat, hatchery, and food service operations.

Key Features – Meat, Poultry & Hatchery Conveyors:

- SS304/316 hygienic construction with sanitary welds, smooth surfaces, and sloped drainage

- Customizable layouts – straight belt, incline, Z-elevator, curve, accumulation, roller, and crate return conveyors for poultry & meat processing

- Purpose-built for poultry crates, hatchery trays, meat bins, food containers, and cold-chain handling equipment

- Optional inline inspection, pathogen-control modules, and HACCP/FSMS compliance features

- Low OPEX with energy-efficient drives, automated diverters, and reduced manual handling

- PLC/SCADA automation with VFDs, smart sensors, recipe management, and seamless process integration for hatcheries & meat plants

See it in Action

Youtube Video Auto Playing without sound

Need Custom Solutions?

Our team can develop specialized cleaning solutions tailored to your bakery hygiene requirements.

Contact Our Experts