Categories

Pallet Washer

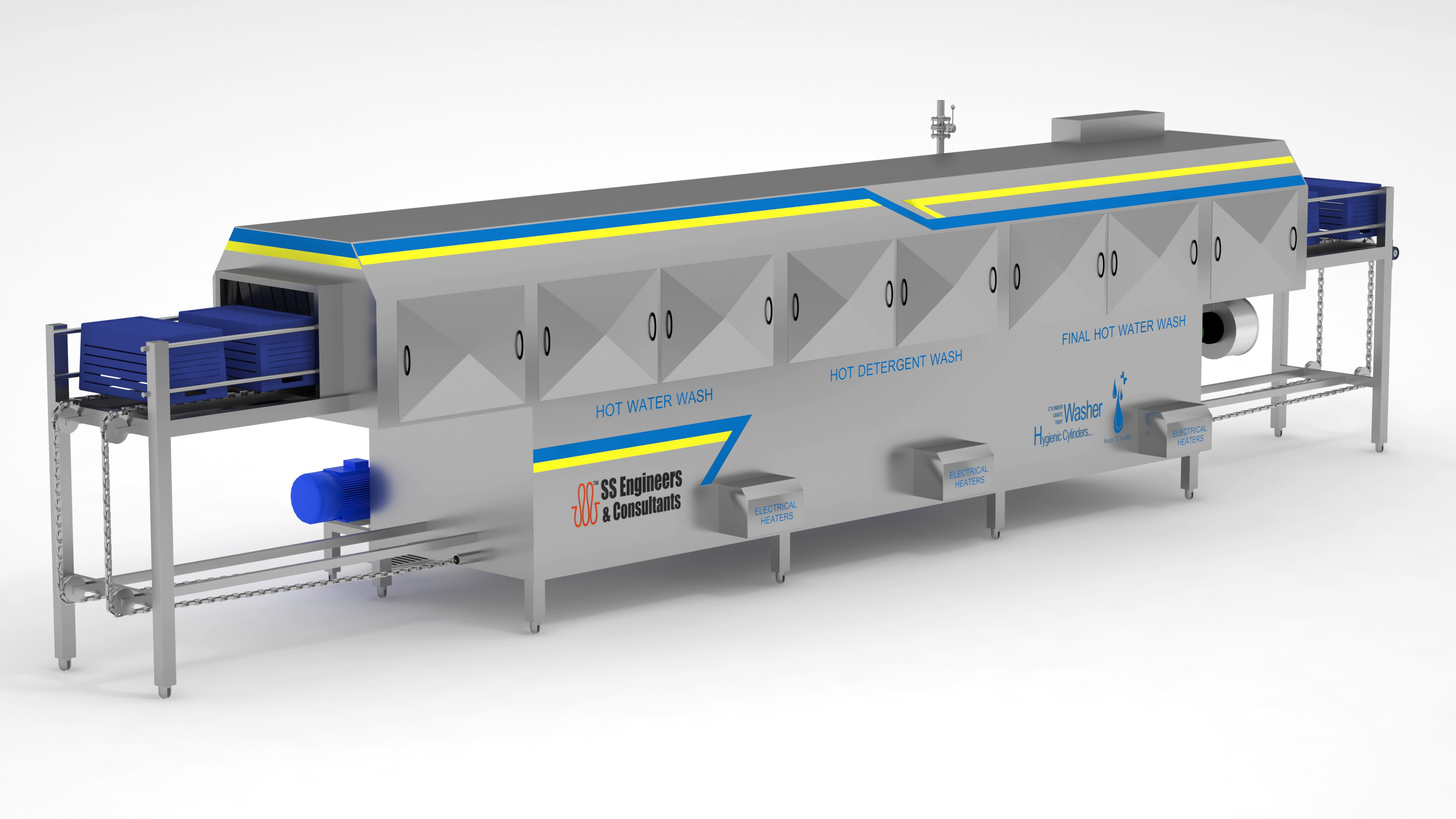

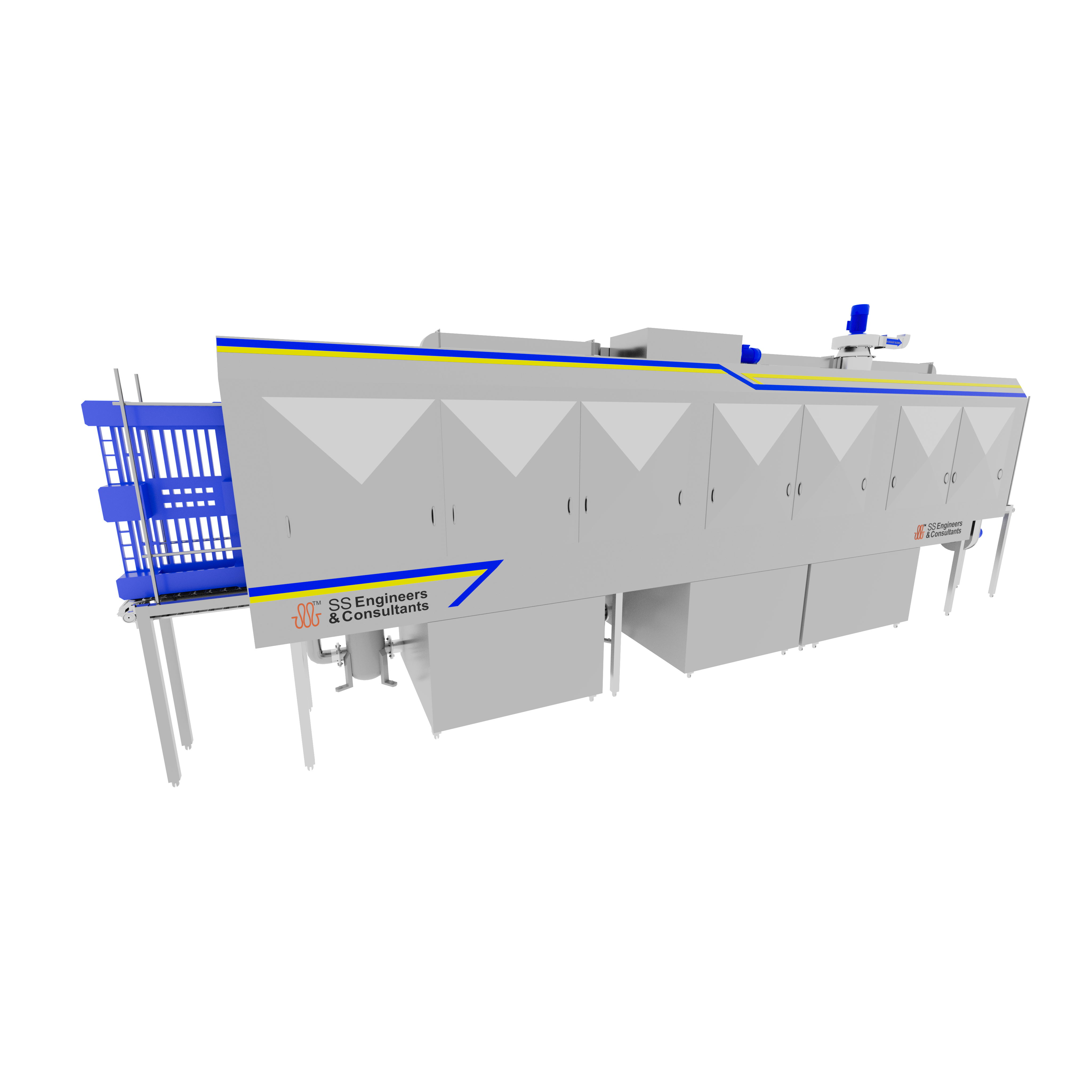

SS Engineers & Consultants provide hygienic, high-throughput washing systems purpose-built for

meat and poultry pallets, logistics crates, and cold-chain handling platforms.

Engineered in

SS304/316 with food-grade seals and sanitary welds, our pallet washers efficiently

remove

blood, fats, proteins, feathers, hatchery debris, and organic soils from returnable

pallets used

in slaughterhouses, hatcheries, and processing facilities. Multi-zone chambers

(pre-wash, detergent wash, rinse, and optional hot-rinse/sanitize at 82–85 °C) combine

high-impact

spray manifolds with adjustable conveyor speeds to deliver consistent, microbiologically safe results

while

minimizing water, chemical, and energy consumption.

Features include CIP-ready tanks with filtration, automated chemical dosing, inline temperature control, easy-access maintenance doors, and hygienic sloped surfaces for full drainage. PLC/SCADA automation with recipe management allows handling of different SKUs such as meat transport pallets, hatchery platforms, protein crates, and cold-chain bins. Optional air-knife blow-off and hot-air drying reduce residual moisture for faster turnaround to cutting halls, packing stations, or cold stores, fully supporting HACCP, FSMS, and global meat-industry hygiene compliance.

Features include CIP-ready tanks with filtration, automated chemical dosing, inline temperature control, easy-access maintenance doors, and hygienic sloped surfaces for full drainage. PLC/SCADA automation with recipe management allows handling of different SKUs such as meat transport pallets, hatchery platforms, protein crates, and cold-chain bins. Optional air-knife blow-off and hot-air drying reduce residual moisture for faster turnaround to cutting halls, packing stations, or cold stores, fully supporting HACCP, FSMS, and global meat-industry hygiene compliance.

Key Features:

- SS304/316 heavy-duty hygienic construction with sanitary welds and pallet-compatible design

- Multi-zone cleaning with high-impact spray manifolds for blood, fats, proteins, feathers, and organic debris

- Recipe-based wash programs for meat transport pallets, hatchery platforms, and cold-chain handling bins

- Optional hot rinse/sanitization (82–85 °C) for pathogen elimination and HACCP/FSMS compliance

- Inline filtration, automated chemical dosing, and water/heat recirculation for lower operating costs (OPEX)

- PLC/SCADA-based automation with conveyor speed control, CIP integration, and optional pallet blow-off/hot-air drying

See it in Action

Youtube Video Auto Playing without sound

Specifications — Poultry & Hatchery Pallet Washer

Comparative specs for 1-Zone, 2-Zone, and 3-Zone models. Toggle to view the complete table. Data based on SS Engineers & Consultants poultry logistics washer configurations.

Fixed Tank — 1, 2 & 3 Zone Models

| Parameter | 1-Zone | 2-Zone | 3-Zone |

|---|---|---|---|

| Capacity (Carriers per Hour) | 10–15 CPH | 30–40 CPH | 50–100 CPH |

| Carrier Types | Pallets / Chick Boxes | Pallets / Chick Boxes | Pallets / Chick Boxes / Egg Trays* |

| Washing Zones / Stages | 1 Zone (Hot Water Wash) | 2 Zones (Hot Detergent + Final Hot Water Rinse) | 3 Zones (Pre-rinse, Hot Detergent, Final Hot Water Rinse) |

| Machine Dimensions (L × W × H) | 3.4 m × 1.6 m × 2.4 m | 5.5 m × 1.8 m × 1.5 m | 8.0 m × 1.8 m × 1.5 m |

| Carrier Dimensions Supported | Up to 1200 × 1100 × 160 mm | Up to 1200 × 1100 × 160 mm | Up to 1200 × 1100 × 160 mm |

| Water Heating Method | Electrical Heaters (30 kW) | Electrical Heaters (60 kW) | Electrical Heaters (90 kW) |

| Steam Heating Facility | Available on request | Available on request | Available on request |

| Spray Jet Pumps | 9 kW | 16.5 kW | 27.6 kW |

| Sanitizer Dosing (Optional) | Automated dosing skid | Automated dosing skid | Automated dosing skid |

| Air Knife System (Optional) | 2 × 7.5 HP Blowers | 2 × 7.5 HP Blowers | 2 × 7.5 HP Blowers |

| Conveyor System | SS 304G Honeycomb Belt + VFD | SS 304G Honeycomb Belt + VFD | SS 304G Honeycomb Belt + VFD |

| Control Panel | RLC or PLC-Based | RLC or PLC-Based | RLC or PLC-Based |

| Water Consumption (per 4–6 hrs) | 600–700 L | 1200–1400 L | 1800–2100 L |

| Total Connected Load (with heaters) | 39 kW (9 + 30) | 76.5 kW (16.5 + 60) | 117.6 kW (27.6 + 90) |

| Steam Consumption (if steam heated) | 90–100 kg/hr | 180–190 kg/hr | 250–280 kg/hr |

| Loading / Unloading | Manual (option: guides) | Manual (option: guides) | Manual (option: guides / transfer) |

| Stacker / De-stacker | Available for horizontal models | Available for horizontal models | Available; egg-tray in/out options |

* Egg-tray compatibility depends on carrier; confirm pitch and support rails during ordering.