Categories

Dish/Plate Washer

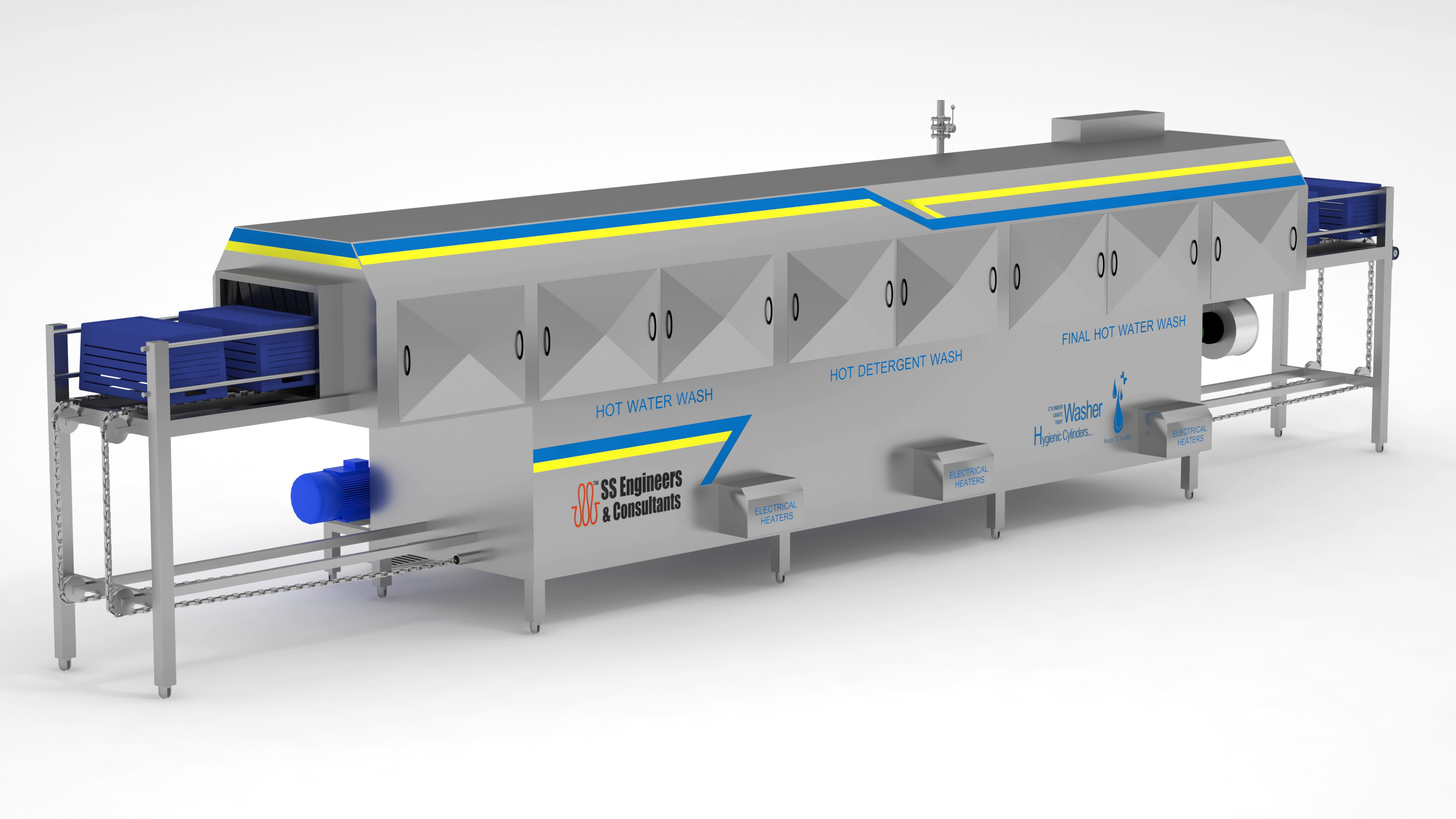

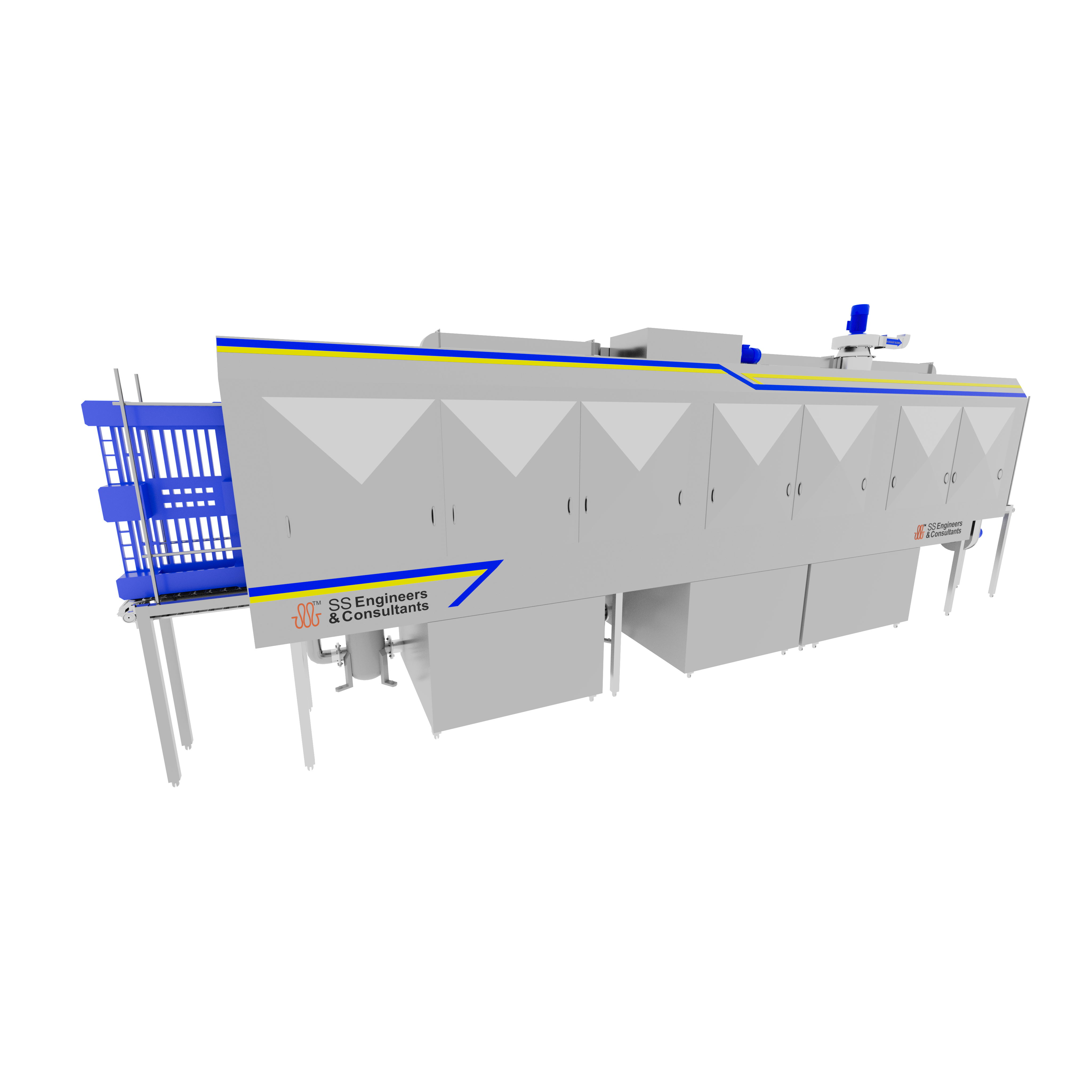

SS Engineers & Consultants provide hygienic, high-throughput dish & plate washer

systems

purpose-built for plates, trays, cutlery, serving ware, and food-contact items widely

used in

canteens, hatchery canteens, poultry farms, slaughterhouse dining halls, and large-scale central

kitchens.

Engineered in SS304/316 with food-grade seals and sanitary welds, our dish & plate

washers

effectively remove proteins, fats, oils, gravies, curries, sauces, and organic

residues.

Conveyor and rack-loading options ensure smooth handling and high-volume cleaning capacity while

reducing labor needs.

Multi-zone cleaning (pre-rinse, detergent wash, rinse, sanitizer, and optional hot-air drying) is delivered through strategically placed spray manifolds and high-pressure rotary nozzles. Recipe-driven wash programs and adjustable wash cycles allow effective cleaning for varied soil loads and utensil types in institutional kitchens and food service facilities.

Features include CIP-ready tanks with filtration, automated chemical dosing, inline temperature monitoring, easy-access service doors, and hygienic sloped surfaces for complete drainage. Optional air-knife or hot-air drying minimizes residual moisture, ensuring dishes and trays are ready for immediate reuse in food service and dining operations.

Fully integrated PLC/SCADA automation with recipe management ensures consistent cleaning, minimized manual handling, and faster turnaround. Supporting HACCP, FSMS, and international food safety standards, the SS Engineers Dish & Plate Washer delivers a reliable, sustainable, and cost-efficient solution for high-volume food service environments.

Multi-zone cleaning (pre-rinse, detergent wash, rinse, sanitizer, and optional hot-air drying) is delivered through strategically placed spray manifolds and high-pressure rotary nozzles. Recipe-driven wash programs and adjustable wash cycles allow effective cleaning for varied soil loads and utensil types in institutional kitchens and food service facilities.

Features include CIP-ready tanks with filtration, automated chemical dosing, inline temperature monitoring, easy-access service doors, and hygienic sloped surfaces for complete drainage. Optional air-knife or hot-air drying minimizes residual moisture, ensuring dishes and trays are ready for immediate reuse in food service and dining operations.

Fully integrated PLC/SCADA automation with recipe management ensures consistent cleaning, minimized manual handling, and faster turnaround. Supporting HACCP, FSMS, and international food safety standards, the SS Engineers Dish & Plate Washer delivers a reliable, sustainable, and cost-efficient solution for high-volume food service environments.

Key Features:

- SS304/316 hygienic construction with sanitary welds, smooth surfaces, and full-drain geometry

- Multi-zone cleaning with high-pressure spray arms for removing oils, proteins, starches, sauces, and gravies

- Flexible wash programs for plates, trays, cutlery, serving ware, and food-contact items

- Optional hot rinse/sanitization (82–85 °C) for pathogen control and HACCP/FSMS compliance

- Inline filtration, automated chemical dosing, and water/energy recirculation for reduced OPEX

- PLC/SCADA automation with conveyor or rack-loading options, recipe management, and optional hot-air/air-knife drying

See it in Action

Youtube Video Auto Playing without sound