Categories

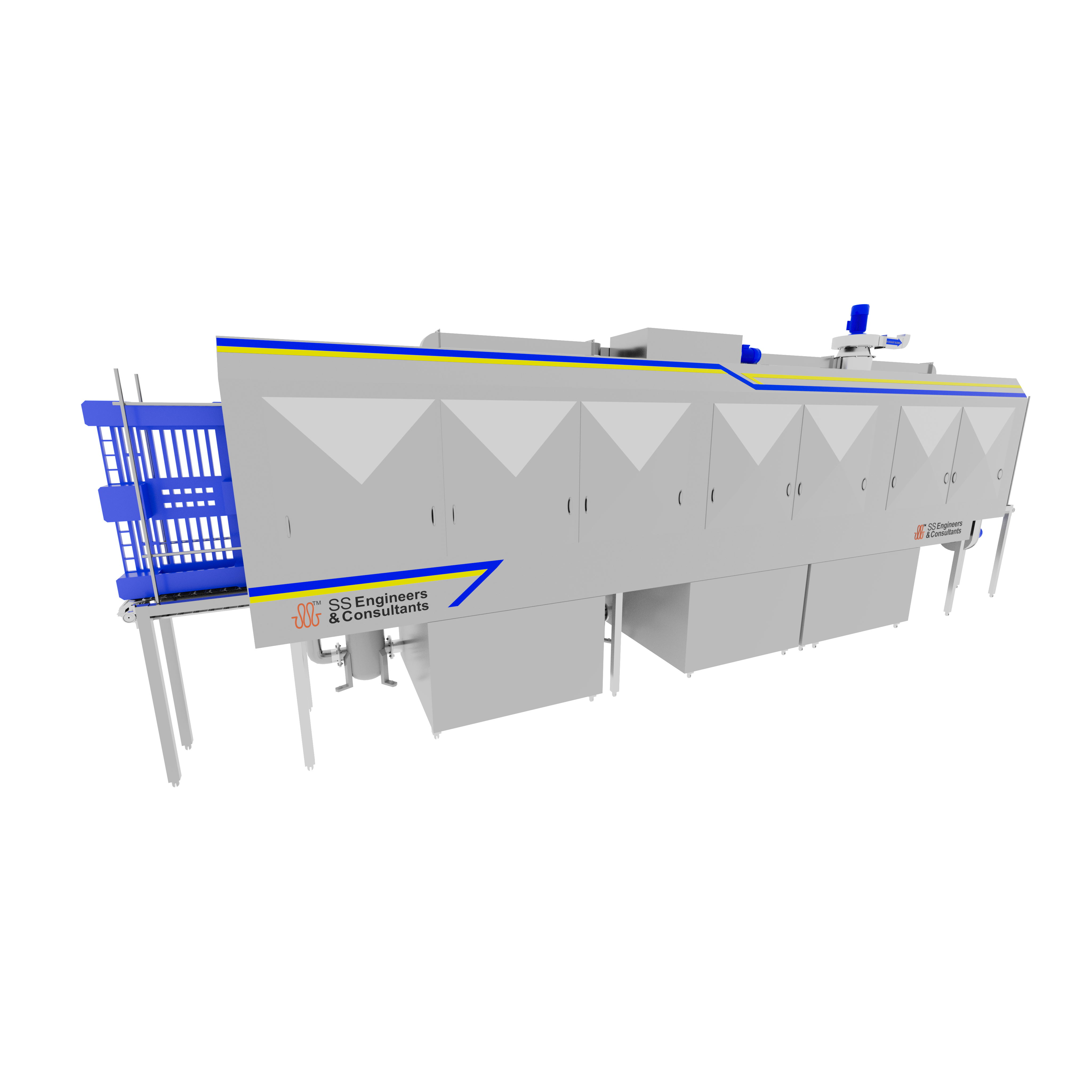

Crate Washer

SS Engineers & Consultants provide hygienic, high-throughput washing systems purpose-built for

meat and poultry crates, hatchery trays, and protein transport bins. Engineered in

SS304/316 with food-grade seals and sanitary welds, our meat & poultry crate

washers

efficiently remove blood, fats, proteins, feathers, hatchery debris, feed residues, and organic

soils.

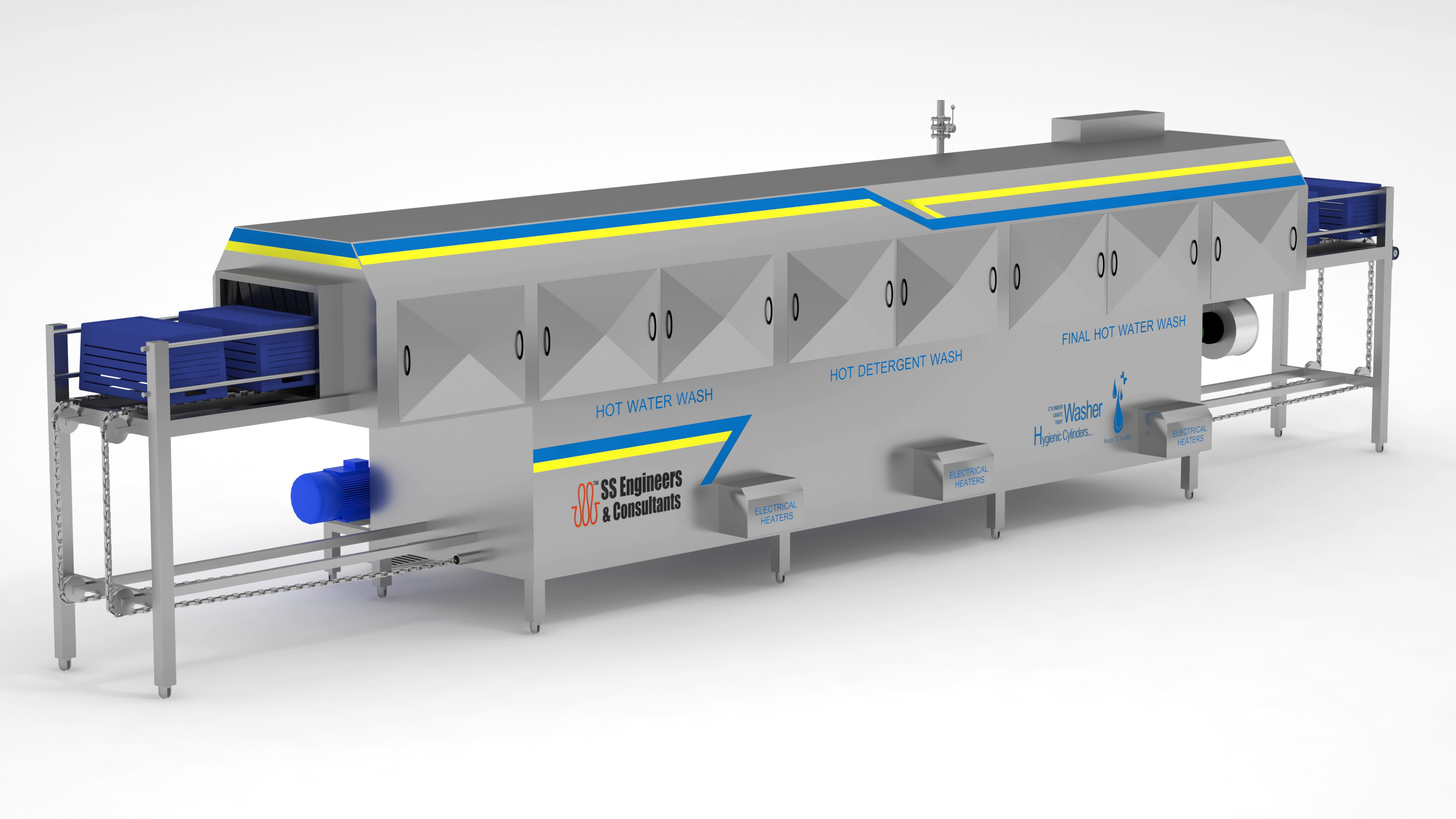

Multi-zone chambers (pre-wash, detergent wash, rinse, and optional hot-rinse/sanitize at

82–85 °C)

combine high-impact spray patterns with adjustable conveyor speeds to deliver consistent,

microbiologically

safe results while minimizing water, chemical, and energy consumption.

Features include CIP-ready tanks with filtration, automated chemical dosing, inline temperature control, easy-access maintenance doors, and hygienic sloped surfaces for full drainage. PLC/SCADA automation with recipe management allows handling of different SKUs such as poultry transport crates, hatcher baskets, egg-handling trays, and protein bins. Optional air-knife blow-off and hot-air drying reduce residual moisture for faster turnaround to hatchery, slaughter, or cold-chain areas, fully supporting HACCP, FSMS, and meat-industry hygiene compliance.

Features include CIP-ready tanks with filtration, automated chemical dosing, inline temperature control, easy-access maintenance doors, and hygienic sloped surfaces for full drainage. PLC/SCADA automation with recipe management allows handling of different SKUs such as poultry transport crates, hatcher baskets, egg-handling trays, and protein bins. Optional air-knife blow-off and hot-air drying reduce residual moisture for faster turnaround to hatchery, slaughter, or cold-chain areas, fully supporting HACCP, FSMS, and meat-industry hygiene compliance.

Key Features:

- SS304/316 hygienic construction with sanitary welds and full-drain geometry

- Multi-zone cleaning with high-impact spray manifolds for blood, fats, proteins, feathers, and hatchery debris

- Recipe-based programs for poultry crates, egg-handling trays, hatcher baskets, and protein bins

- Optional hot rinse/sanitization (82–85 °C) for pathogen control and HACCP/FSMS compliance

- Inline filtration, automated chemical dosing, and water/heat recirculation for reduced OPEX

- PLC/SCADA-based automation with conveyor speed control, CIP integration, and optional air-knife/hot-air drying

See it in Action

Youtube Video Auto Playing without sound

Specifications — Poultry Crate Washer (Separate Tank)

Two separate models. Expand to view all rows; only horizontal scrolling is used when needed.

Poultry — 2-Zone

| Parameter | Specification |

|---|---|

| Capacity | 100–300 crates/trays per hour (VFD controlled) |

| Crate/Tray Size | 650 × 450 × 315 mm |

| Machine Type / Tanks | Separate-tank; tanks beneath zones; filtered return |

| Configuration | Straight, single track/chain conveyor |

| Washing Sequence | Pre-wash → Hot detergent → Hot water rinse → (optional) hot-air zone |

| Nozzle Pressure (detergent) | 4.0–5.0 kg/cm² |

| Water Temperatures | Det./rinse 60–70 °C; hot-water zone 55–65 °C |

| Hot-Air / Air-Knife | 80–110 °C (heater/radiator) or air-knife option |

| Electric Power | ~32.5 HP (pumps, motor & blowers), 415 V, 3-ph, 50 Hz |

| Pumps | As per 2-zone poultry configuration |

| Conveyor Motor | 1 × 2 HP |

| Blowers | 7.5 HP × 2 (air-knife) or 2 HP × 4 (hot-air) |

| Electrical Panel | SS304G enclosure; ON/OFF; indicators; E-stop |

| Temperature Control | Provided for detergent and rinse sections |

| Main Enclosure | SS304, 2 mm |

| Under Frame | SS304 hollow square 50 × 50 × 2 mm |

| Conveyor Chain | SS link chain with drive & tensioning |

| Washing Stations | SS piping with detachable jetting pipes |

| Valves | SS ball valves |

| Finish | All SS surfaces polished to 150-grit |

| Compressed Air | 3–4 bar supply required |

Poultry — 3-Zone

| Parameter | Specification |

|---|---|

| Capacity | 500–600 crates/trays per hour (VFD controlled) |

| Crate/Tray Size | 650 × 450 × 315 mm |

| Machine Type / Tanks | Separate-tank; tanks beneath zones; filtered return |

| Configuration | Straight, single track/chain conveyor |

| Washing Sequence | Pre-rinse → Hot water → Hot detergent → Final hot water → Hot-air zone |

| Nozzle Pressure (det. & final) | 4.0–5.0 kg/cm² |

| Water Temperatures | Det./rinse 60–70 °C; final 55–65 °C |

| Hot-Air / Air-Knife | 80–110 °C (heater/radiator) or air-knife option |

| Electric Power | As per 3-zone poultry configuration (pumps, drive & blowers) |

| Pumps | As per 3-zone poultry configuration |

| Conveyor Motor | 1 × 2 HP |

| Blowers | 7.5 HP × 2 (air-knife) or 2 HP × 4 (hot-air) |

| Electrical Panel | SS304G enclosure; ON/OFF; indicators; E-stop |

| Temperature Control | Provided for detergent and rinse sections |

| Main Enclosure | SS304, 2 mm |

| Under Frame | SS304 hollow square 50 × 50 × 2 mm |

| Conveyor Chain | SS link chain with drive & tensioning |

| Washing Stations | SS piping with detachable jetting pipes |

| Valves | SS ball valves |

| Finish | All SS surfaces polished to 150-grit |

| Compressed Air | 3–4 bar supply required |