Crate Washer

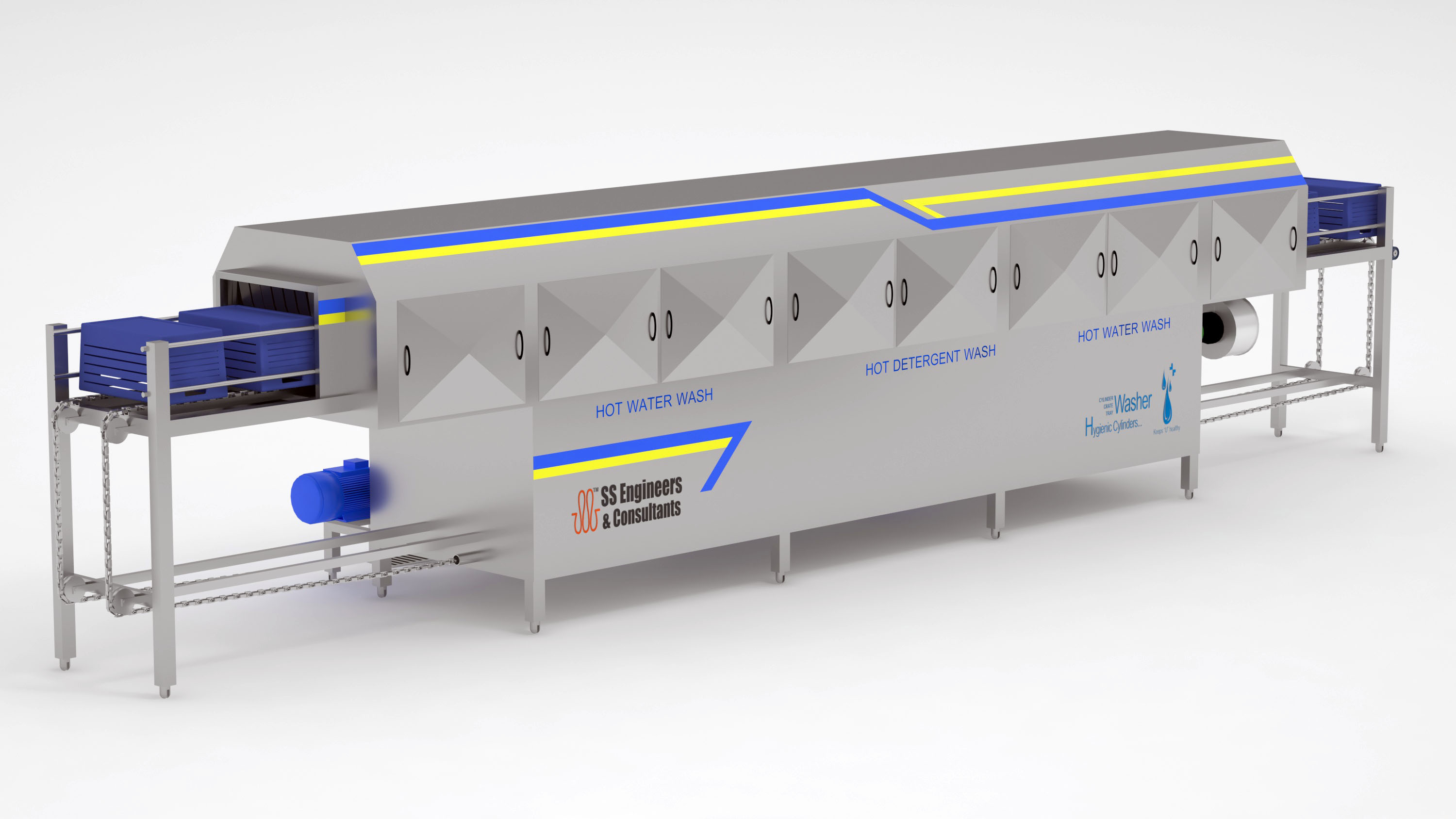

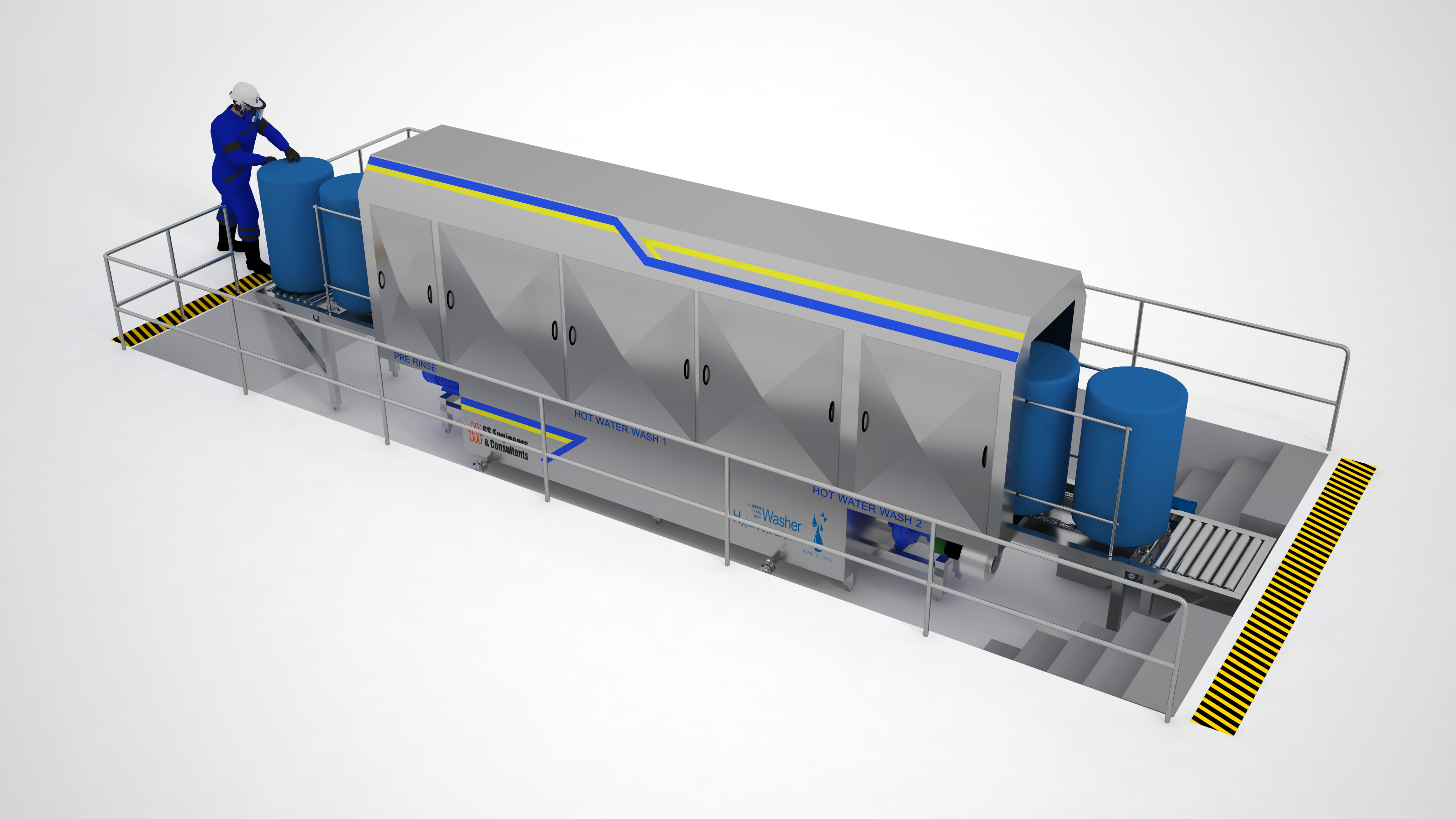

Our RTS Food & Beverage Crate Washer is designed for hygienic, high-throughput cleaning of plastic crates, bins, and trays used in dairy, beverage, meat, bakery, and fresh produce operations. The tunnel follows a multi-stage process of pre-rinse → detergent wash → fresh-water rinse → optional sanitizer → high-velocity air blow-off, ensuring consistent cleaning and microbial safety while conserving water and chemicals through closed-loop filtration and recirculation.

The system is equipped with configurable spray manifolds, adjustable conveyor speed, and recipe-driven wash programs to handle diverse soils such as milk residues, starches, sugars, proteins, oils, and organic matter without risk of cross-contamination. Hygienic SS304/316 construction with sanitary welds, inline basket filters, wedge-screen fines removal, and automated chemical dosing further enhance efficiency and compliance with food safety standards.

With a throughput capacity of up to 500 crates/hour (scalable with multi-lane designs), this washer is ideal for centralized cleaning zones within food processing plants. Its robust design and automation features help minimize operating costs (OPEX) while supporting HACCP, FSMS, and export-grade hygiene compliance for modern food & beverage industries.

Pallet Washer

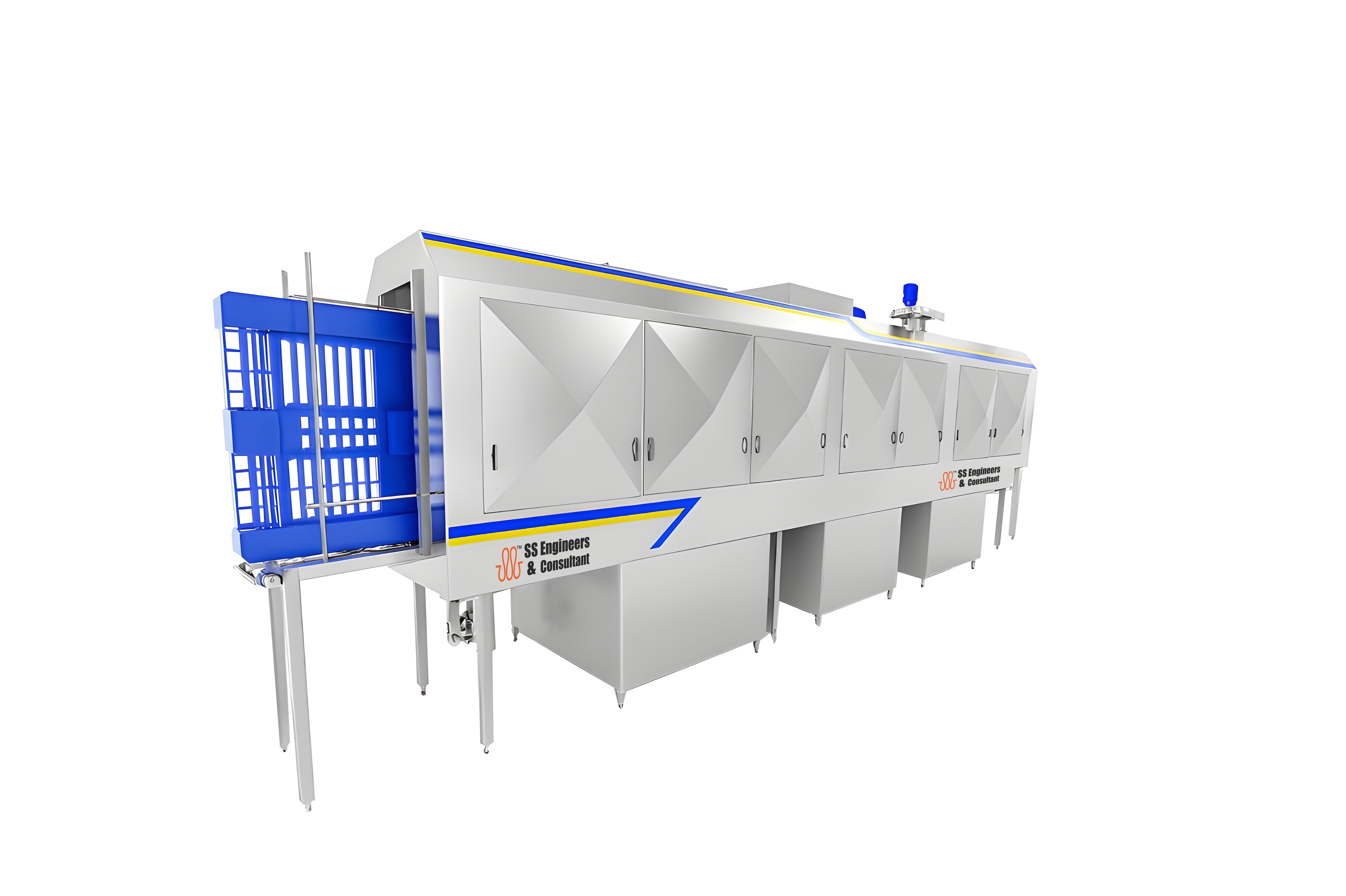

Our RTS Food & Beverage Pallet Washer is engineered for heavy-duty, hygienic cleaning of pallets used in dairy, beverage, meat, seafood, bakery, and cold chain logistics. The tunnel incorporates staged pre-rinse → detergent wash → fresh-water rinse → optional sanitizer → air knife or hot-air drying, ensuring pallets are sanitized and ready for reuse while conserving water and detergent through recirculation and filtration systems.

The system features high-impact spray manifolds, adjustable conveyor speed, and recipe-based wash cycles to tackle soils such as proteins, blood residues, oils, starches, sugar films, and dust. Built with robust SS304/316 stainless steel and sanitary welds, it integrates wedge-screen solids removal, inline filtration, and automated chemical dosing to maintain hygiene and reduce operating costs. Optional features include heat recovery and automated pallet stacking/unstacking for improved productivity.

Capable of handling 50–150 pallets per hour (expandable with multi-lane or dual-track designs), this washer is ideal for centralized washing stations in high-volume food and beverage operations. Its compliance with HACCP, FSMS, and export hygiene standards makes it a reliable backbone for ensuring safe logistics, reducing contamination risk, and supporting lean, automated supply chains.

The SS Engineers Drum Washer is designed for hygienic cleaning of reusable drums and barrels widely used in the dairy, beverage, brewery, edible oil, fruit pulp, and sauce processing sectors. The washing cycle includes staged pre-rinse → detergent wash → fresh-water rinse → optional sanitizer → hot-air or air-knife drying, ensuring that drums are thoroughly cleaned and sanitized for direct use in food-grade applications.

Constructed from SS304/316 with sanitary welds, the system integrates high-impact rotary spray nozzles, adjustable drum holders, and recipe-based wash programs to effectively remove residues such as milk fats, juices, purees, pulps, syrups, oils, and sugar films. Inline filtration, wedge-screen solids removal, and automated chemical dosing ensure consistent hygiene while minimizing water and chemical consumption. Optional steam or hot-water sanitization can be added for high-risk product categories.

With a throughput of 30–80 drums per hour, this washer is ideal for centralized cleaning stations in food and beverage plants. Its automation, low maintenance requirements, and compliance with HACCP, FSMS, and export standards provide processors with a reliable solution for maintaining hygiene, reducing contamination risks, and ensuring safe handling of liquid food ingredients.

The SS Engineers Dish & Plate Washer is engineered for hygienic, large-scale cleaning of plates, trays, and cutlery used in dairies, food processing units, central kitchens, bakeries, beverage plants, and catering operations. Its multi-stage process of pre-rinse → detergent wash → fresh-water rinse → sanitizer → hot-air drying ensures food-contact surfaces are safe, spotless, and ready for immediate reuse while conserving water and chemicals through recirculation systems.

Built from food-grade SS304/316 with sanitary welds, the system incorporates modular conveyor or rack-loading designs, high-pressure spray manifolds, and recipe-based wash programs to tackle soils such as dairy residues, oils, starches, sauces, gravies, and proteins. Inline filtration, automatic detergent and sanitizer dosing, and closed-loop water recovery help maintain consistent hygiene levels while reducing operational costs (OPEX).

With a throughput capacity of 500–2,000 plates per hour (depending on configuration), this washer is ideal for centralized washing zones in large-scale kitchens and food plants. Designed to meet HACCP and FSMS standards, it provides processors and caterers with a reliable solution that reduces manual handling, prevents cross-contamination, and ensures compliance with modern food & beverage hygiene requirements.

The SS Engineers Food & Beverage Conveyor System is designed for hygienic, efficient transfer of raw and processed products across dairy, beverage, fruit & vegetable, meat, bakery, and ready-to-eat food plants. These conveyors seamlessly link washers, cutters, fillers, and packaging stations, ensuring a continuous flow of ingredients, crates, trays, and packed goods without manual bottlenecks. Configurations include straight belt, Z-elevator, incline, curve, accumulation, roller, and chain conveyors tailored to food processing environments.

Constructed from SS304/316 with sanitary welds and food-grade belts, the systems feature sloped drainage, smooth surfaces, and tool-less access for easy cleaning and compliance with hygiene norms. Optional CIP integration, inline inspection stations, reject spurs, and auto-diverters enable safe handling of milk pouches, juice bottles, bakery trays, produce bins, or frozen packs. PLC/SCADA controls with VFDs and sensors provide recipe-based automation, precise speed control, and protection of delicate food products from damage or contamination.

Scalable to handle from small kitchen batches up to high-capacity processing lines, these conveyors minimize manual handling, improve plant ergonomics, and ensure consistent throughput. Fully aligned with HACCP, FSMS, and export hygiene standards, the SS Engineers Conveyor System forms the reliable backbone for modern food & beverage operations, enabling lean production and safe product movement from raw material intake to final packaging.