Categories

Crate Washer

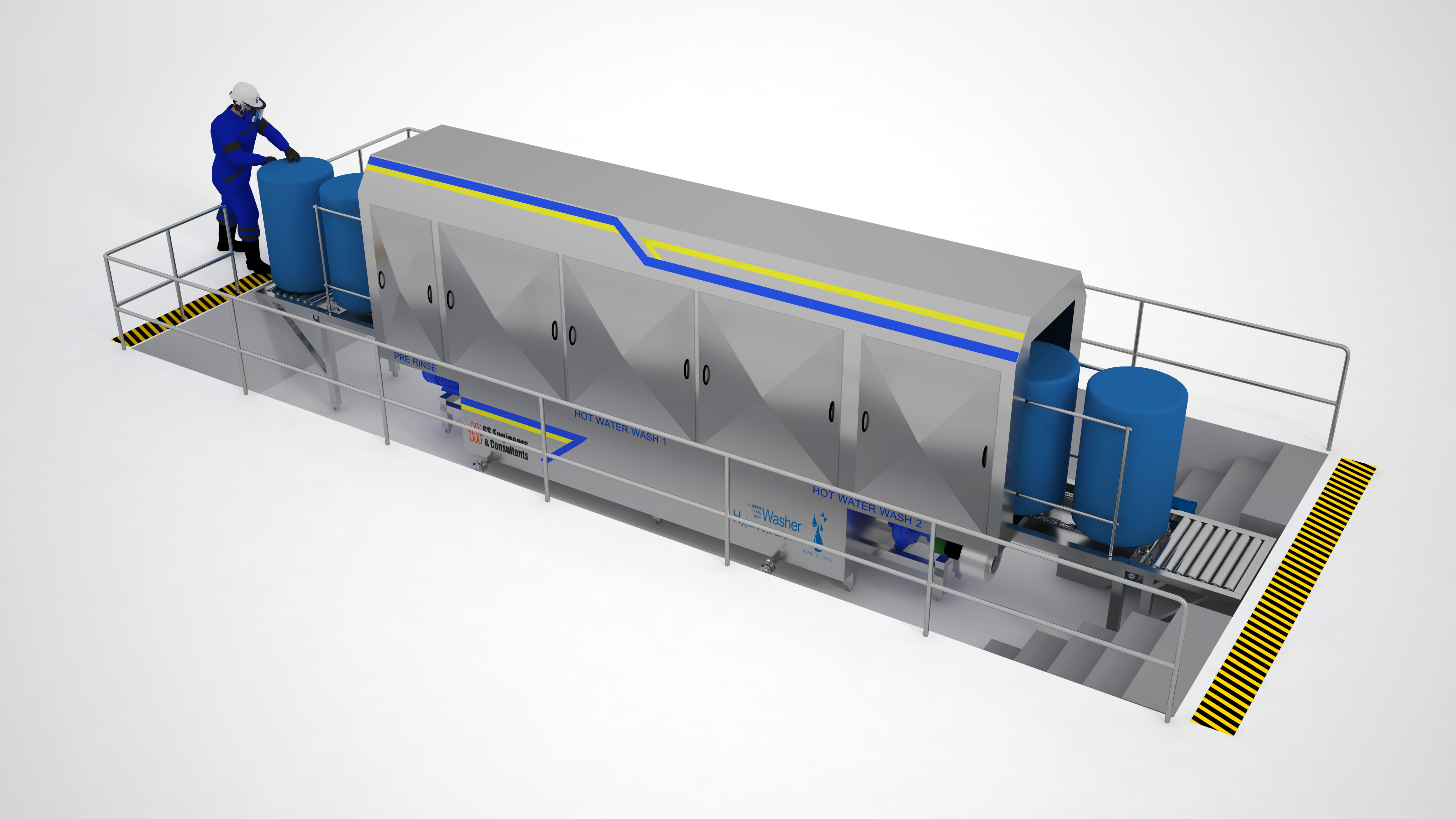

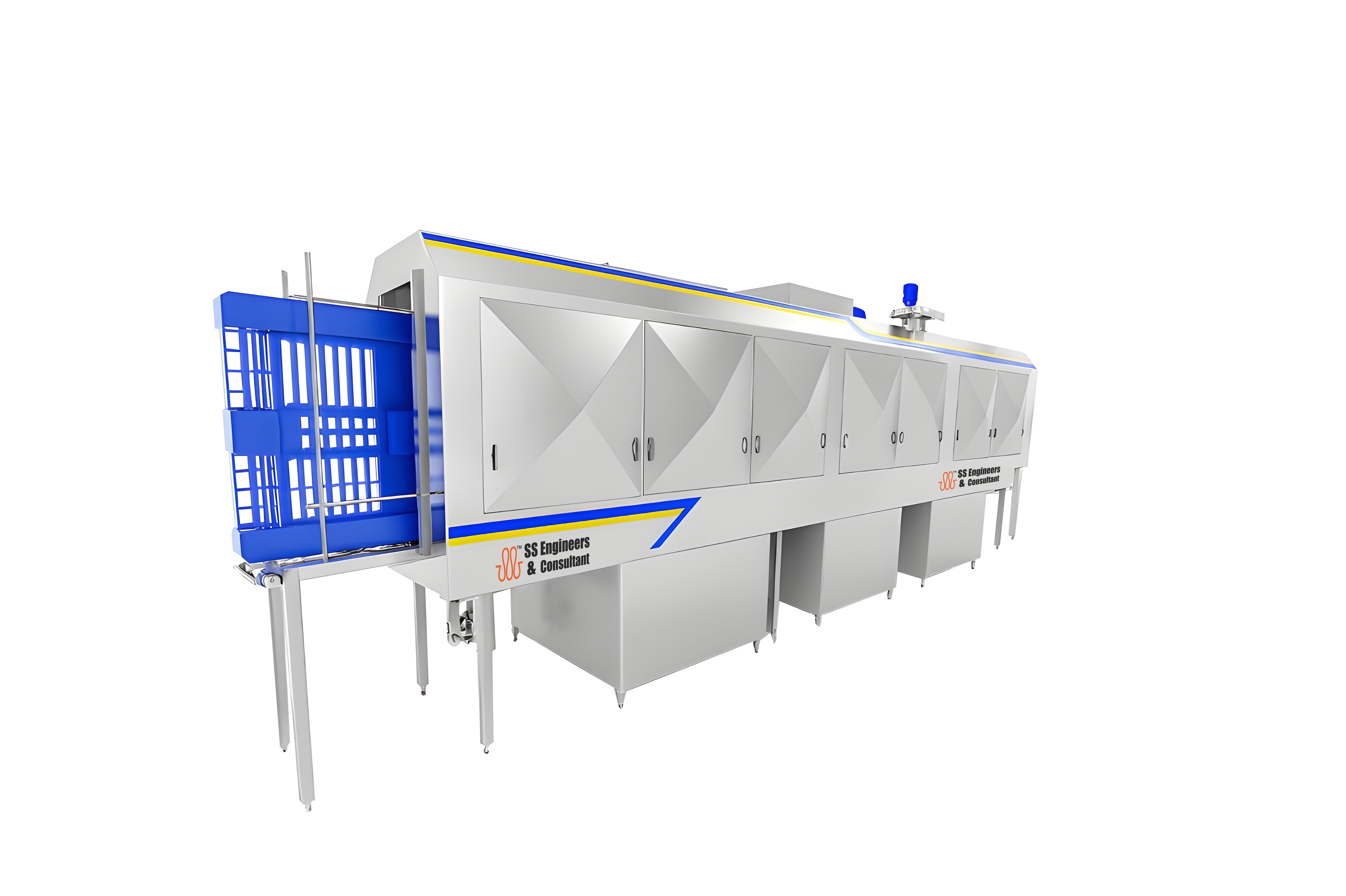

The SS Engineers RTS Food & Beverage Crate Washer is engineered for high-throughput,

hygienic cleaning of

dairy, beverage, bakery, and fresh produce crates, trays, and bins. Built with

SS304/316 stainless steel,

sanitary welds, and food-grade seals, the system is designed to remove dairy residues, starches,

juices, oils, pulps,

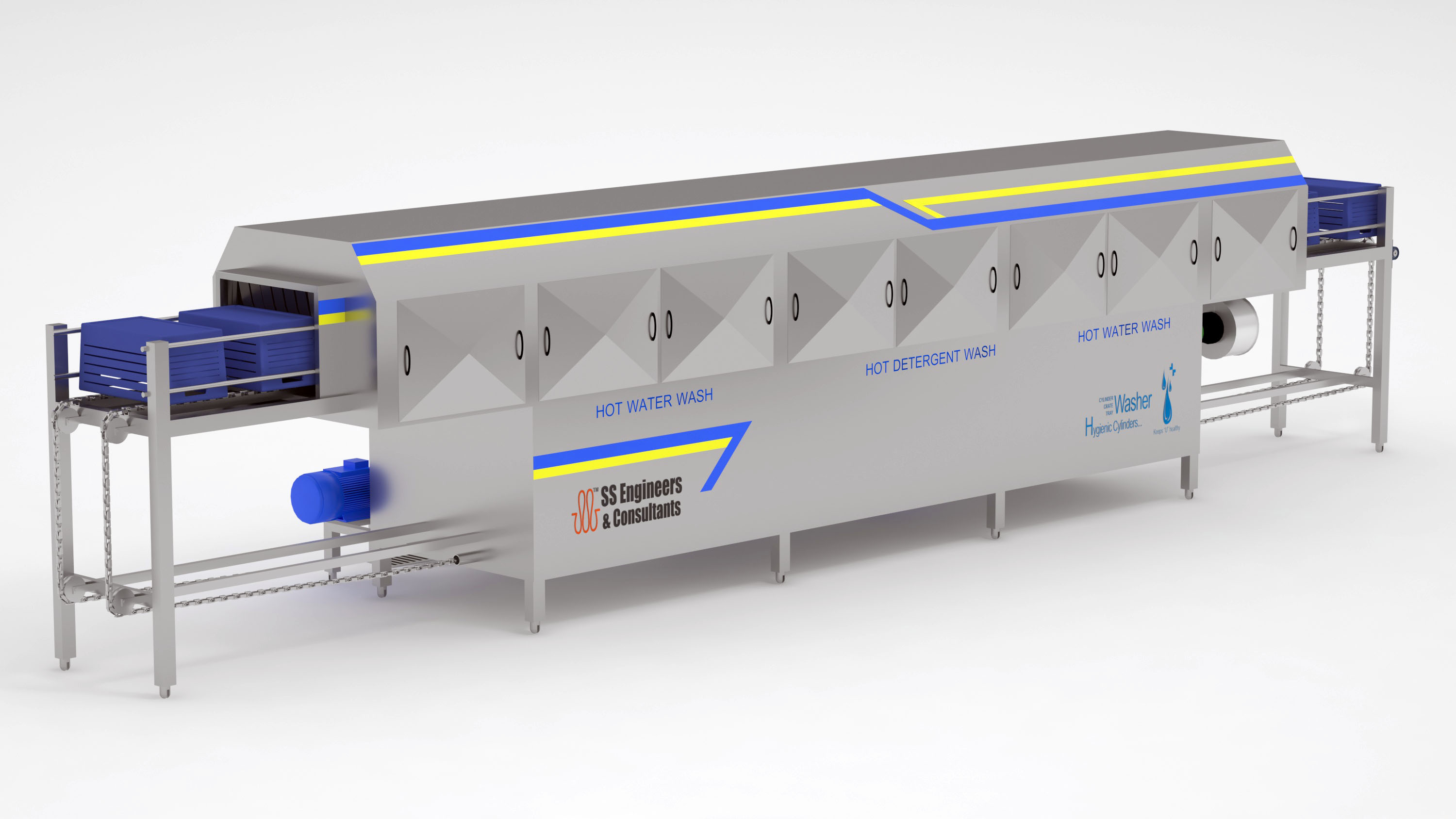

and organic matter that accumulate during handling and processing. Its multi-zone design

with pre-rinse, detergent wash,

fresh-water rinse, and optional hot sanitization (82–85 °C) ensures safe, consistent, and

resource-efficient cleaning.

Key features include CIP-ready tanks with inline filtration, automatic

detergent/sanitizer dosing, precise

temperature control, and PLC/SCADA automation with recipe management for different crate sizes and

product categories such as

milk crates, bakery trays, beverage bins, and fruit & vegetable containers. Hygienic

sloped surfaces ensure

full drainage, while quick-access doors simplify maintenance. Optimized water, energy, and chemical

recovery systems reduce OPEX

while delivering reliable food-grade hygiene.

Optional add-ons include air-knife drying modules for moisture removal, heat

recovery systems for

energy efficiency, and automated crate handling conveyors for seamless integration with

sorting, filling, and packing

lines. Fully compliant with HACCP, FSMS, and export hygiene standards, the SS Engineers

RTS Food & Beverage Crate Washer

supports processors in achieving safe, consistent cleanliness while reducing labor and improving food

safety across the supply chain.

Key Features – SS Engineers RTS Food & Beverage Crate Washer:

- SS304/316 food-grade stainless steel with sanitary welds and hygienic sloped drainage

- Multi-zone wash cycle: pre-rinse → detergent wash → fresh-water rinse → optional hot sanitization

- Removes dairy residues, starches, pulps, juices, oils, and organic matter from crates and bins

- High-impact spray manifolds with adjustable conveyor speed for varied food processing loads

- Recipe-based programs adaptable for milk crates, beverage bins, bakery trays, and produce containers

- CIP-ready tanks with inline filtration, wedge-screen solids removal, and automatic chemical dosing

- Hot rinse/sanitization at 82–85 °C ensuring HACCP, FSMS, and food export hygiene compliance

- Water and heat recovery systems for energy efficiency and reduced operating costs (OPEX)

- PLC/SCADA automation with recipe management, cycle logging, and performance monitoring

- Optional air-knife drying and automated crate handling conveyors for seamless integration

See it in Action

Youtube Video Auto Playing without sound

Need Custom Solutions?

Our team can develop specialized cleaning solutions tailored to your bakery hygiene requirements.

Contact Our Experts