Categories

Conveyor System

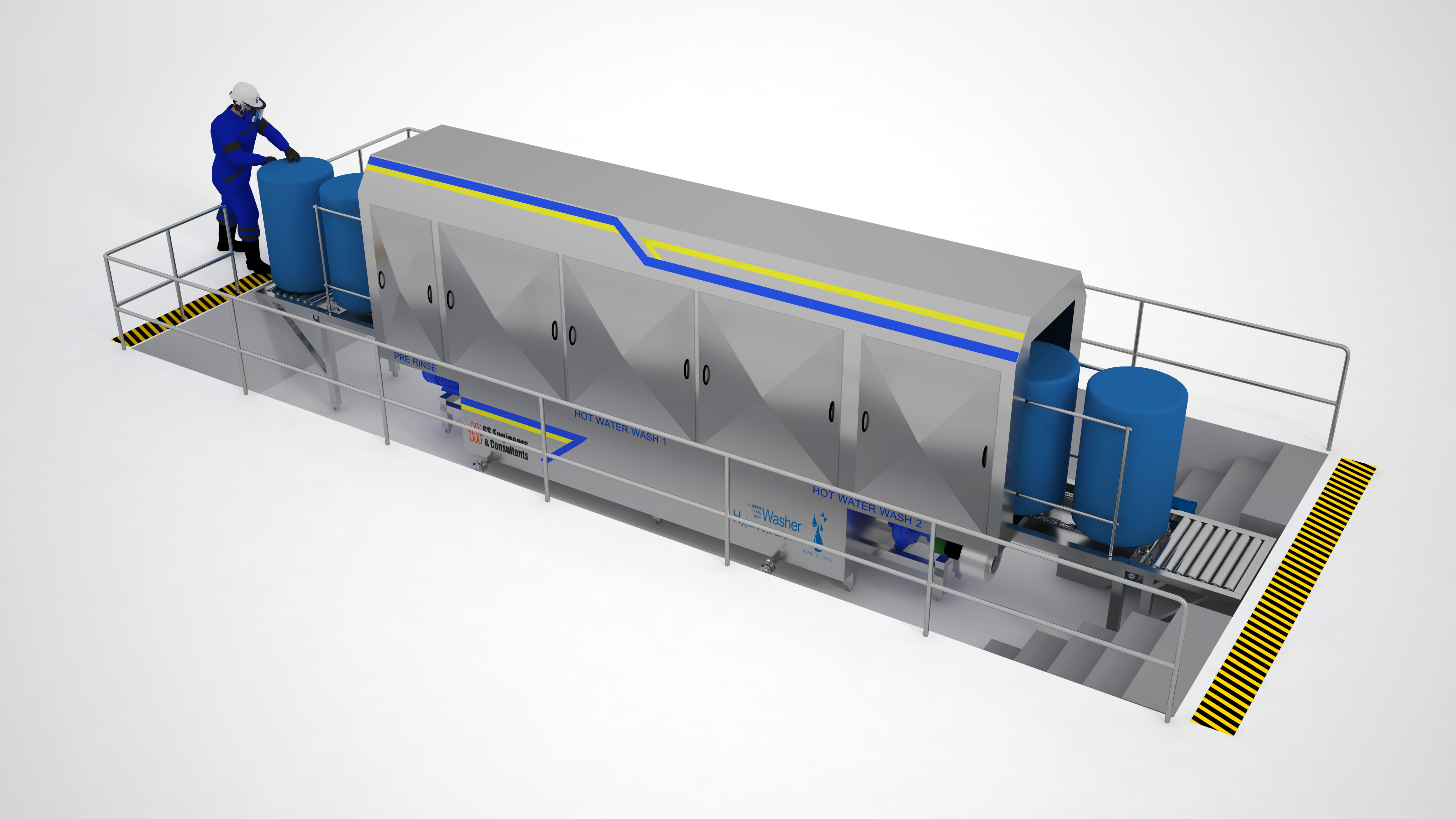

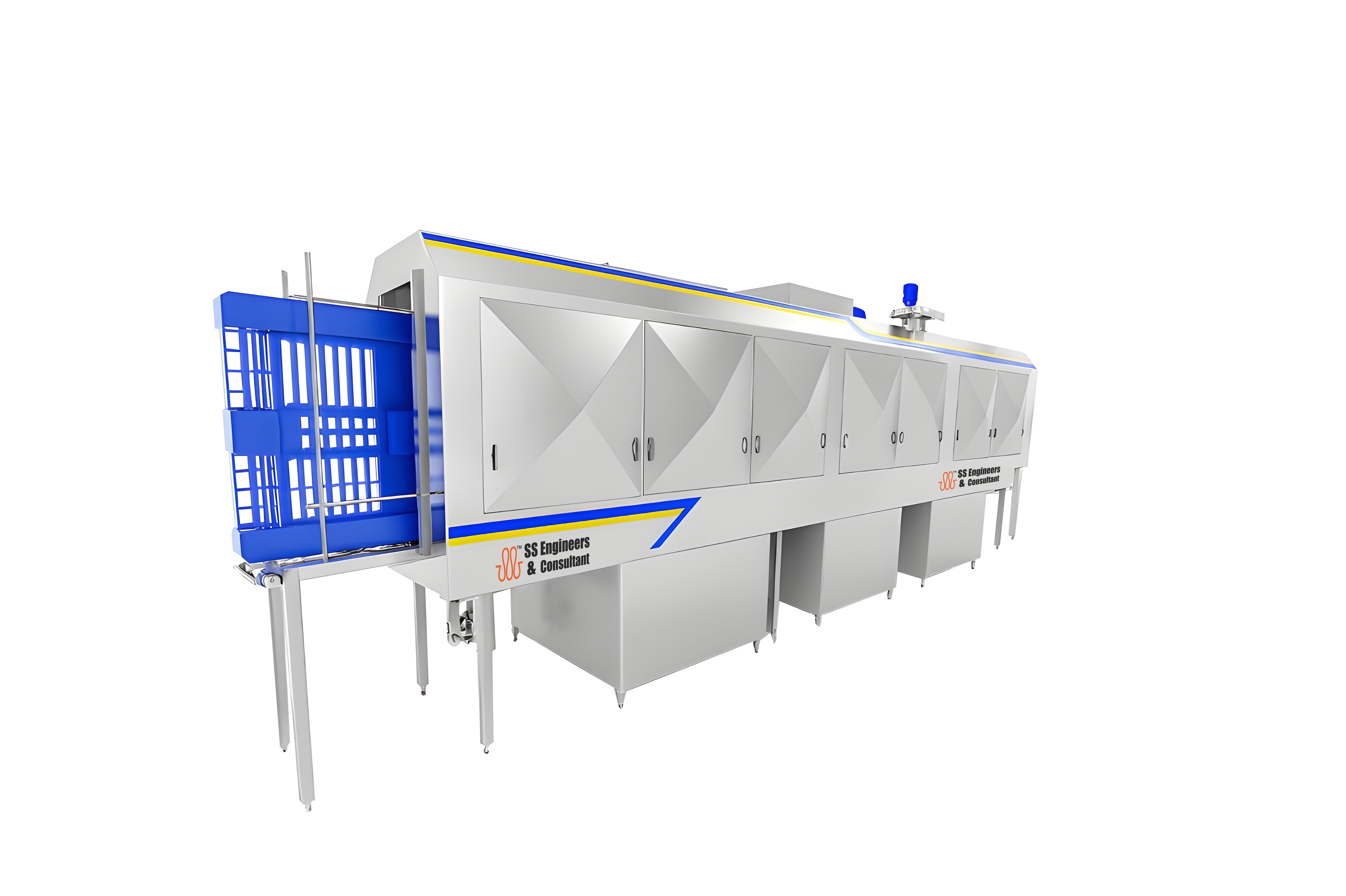

The SS Engineers RTS Food & Beverage Conveyor System is engineered for hygienic,

high-throughput transfer of

dairy, beverage, bakery, fruit, vegetable, and ready-to-eat food products. Built with

SS304/316 stainless steel,

sanitary welds, and food-grade belts, the system ensures smooth, contamination-free movement of raw

materials, crates, trays, and packaged goods.

Configurations include straight, incline, Z-elevator, curve, roller, and chain conveyors

designed to connect washing, processing, and packaging lines

with safe and efficient flow control.

Key features include food-grade conveyor belts, modular frames, hygienic sloped surfaces, and

tool-less access for sanitation.

PLC/SCADA automation enables recipe-driven speed control, cycle monitoring, and integration with

upstream and downstream equipment.

Optional inline inspection stations, reject spurs, and diverters ensure safe handling of sensitive

products such as milk pouches, juice bottles, bakery trays, produce bins, and frozen

packs.

Optimized drive systems, VFDs, and smart sensors reduce manual handling while improving efficiency and

consistency.

Optional add-ons include automated crate and pallet handling modules, heat and

energy recovery systems, and customized layouts

for seamless integration with filling, packing, and cold storage operations. Fully compliant with

HACCP, FSMS, and export hygiene standards,

the SS Engineers RTS Food & Beverage Conveyor System provides processors with a reliable backbone for

safe product transfer, labor reduction,

and streamlined food supply chain operations.

Key Features – SS Engineers RTS Food & Beverage Conveyor System:

- SS304/316 food-grade stainless steel construction with sanitary welds and hygienic sloped surfaces

- Customizable layouts: straight, incline, curve, Z-elevator, roller, and chain conveyors for food applications

- Food-grade modular belts designed for dairy, beverage, bakery, produce, frozen, and ready-to-eat products

- High-efficiency drive systems with adjustable speeds for varied food processing and packaging loads

- Recipe-based automation adaptable for milk pouches, juice bottles, bakery trays, and produce bins

- Optional inline inspection stations, reject spurs, and auto-diverters for safe product handling

- Tool-less access and hygienic design ensuring quick sanitation and reduced downtime

- Energy-efficient operation with optimized motors, water/heat recovery, and reduced OPEX

- PLC/SCADA automation with recipe management, performance monitoring, and system integration

- Optional automated crate/pallet handling modules for seamless connection to washers, fillers, and packing lines

See it in Action

Youtube Video Auto Playing without sound

Need Custom Solutions?

Our team can develop specialized cleaning solutions tailored to your bakery hygiene requirements.

Contact Our Experts