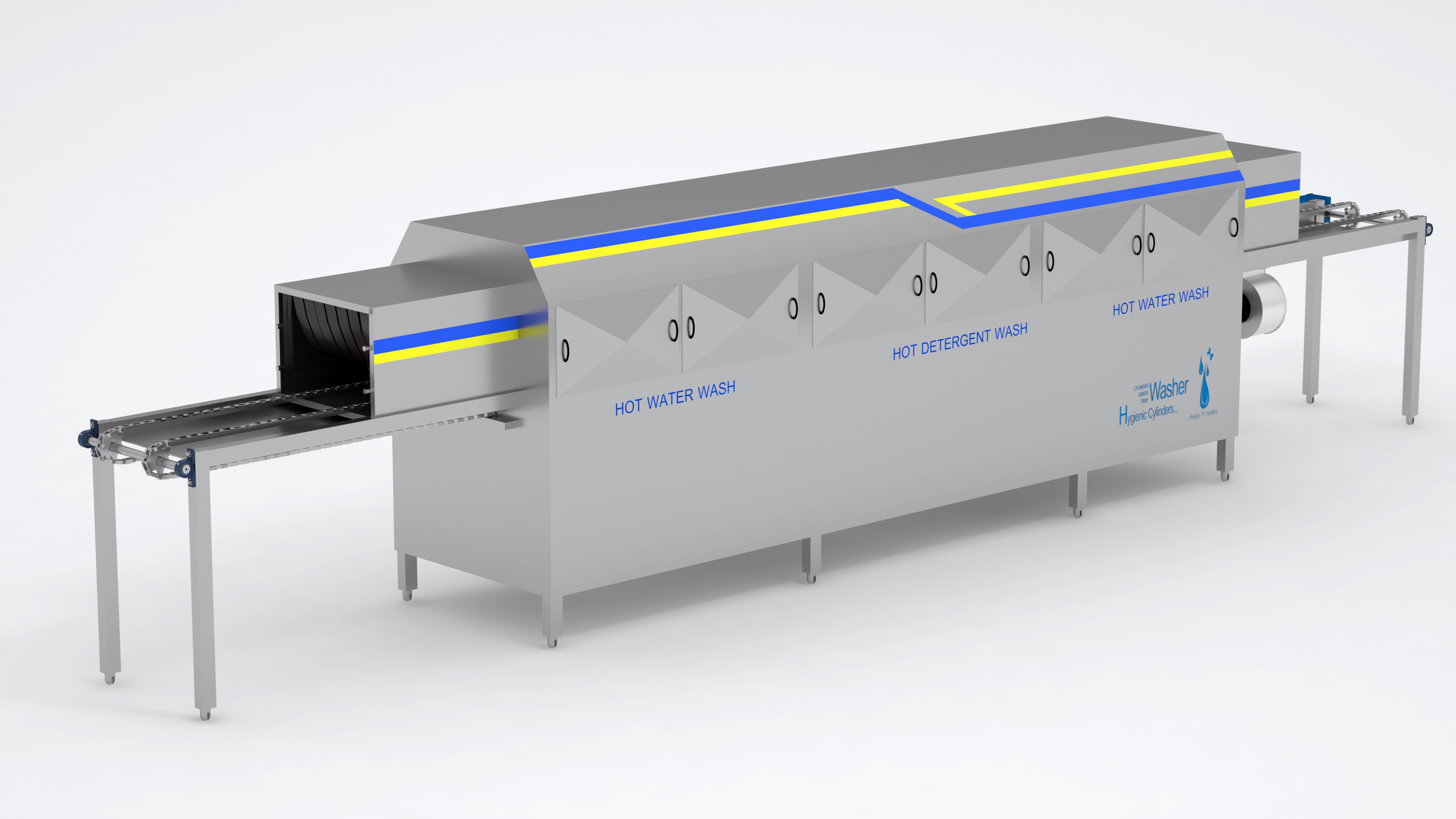

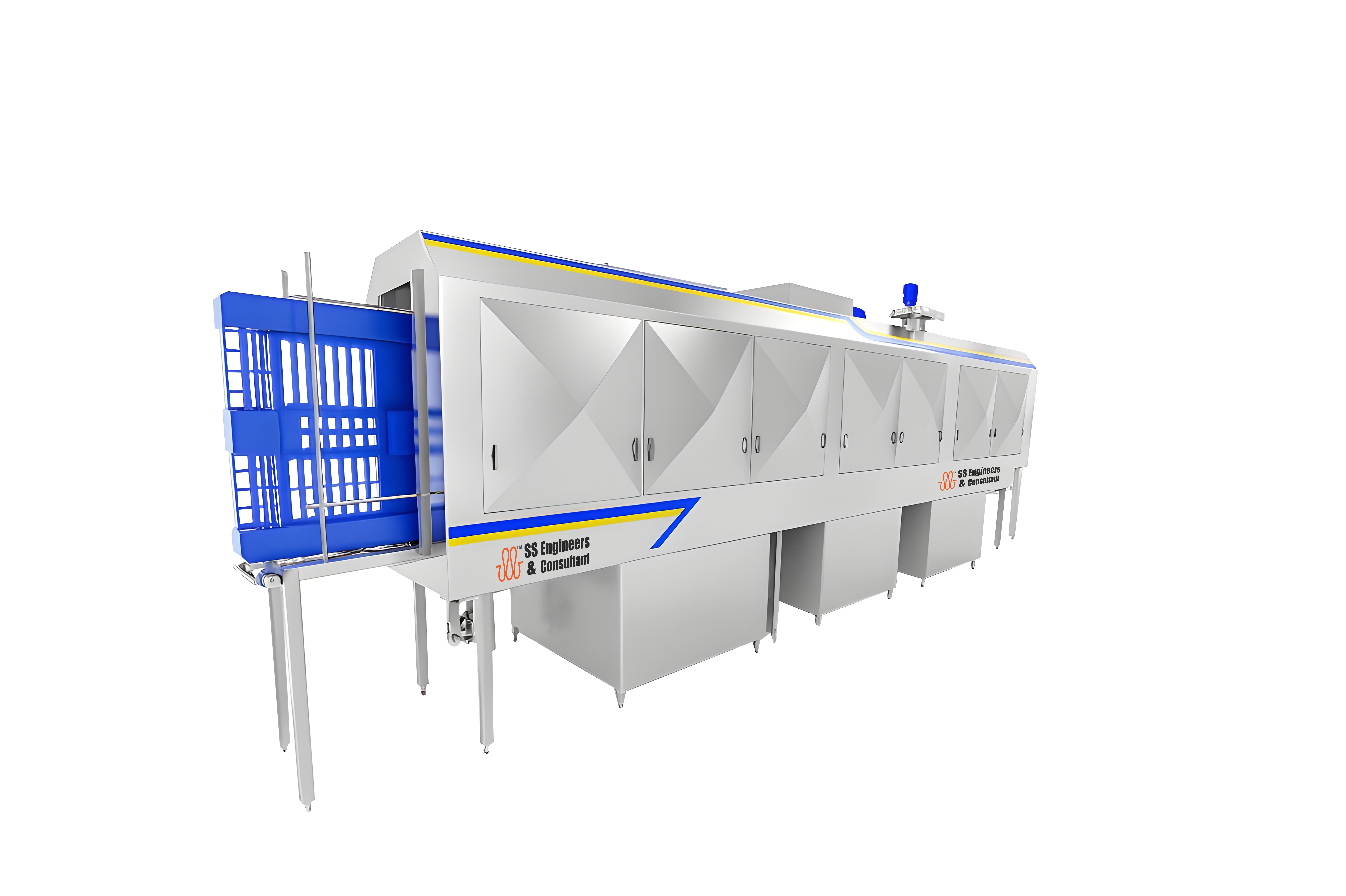

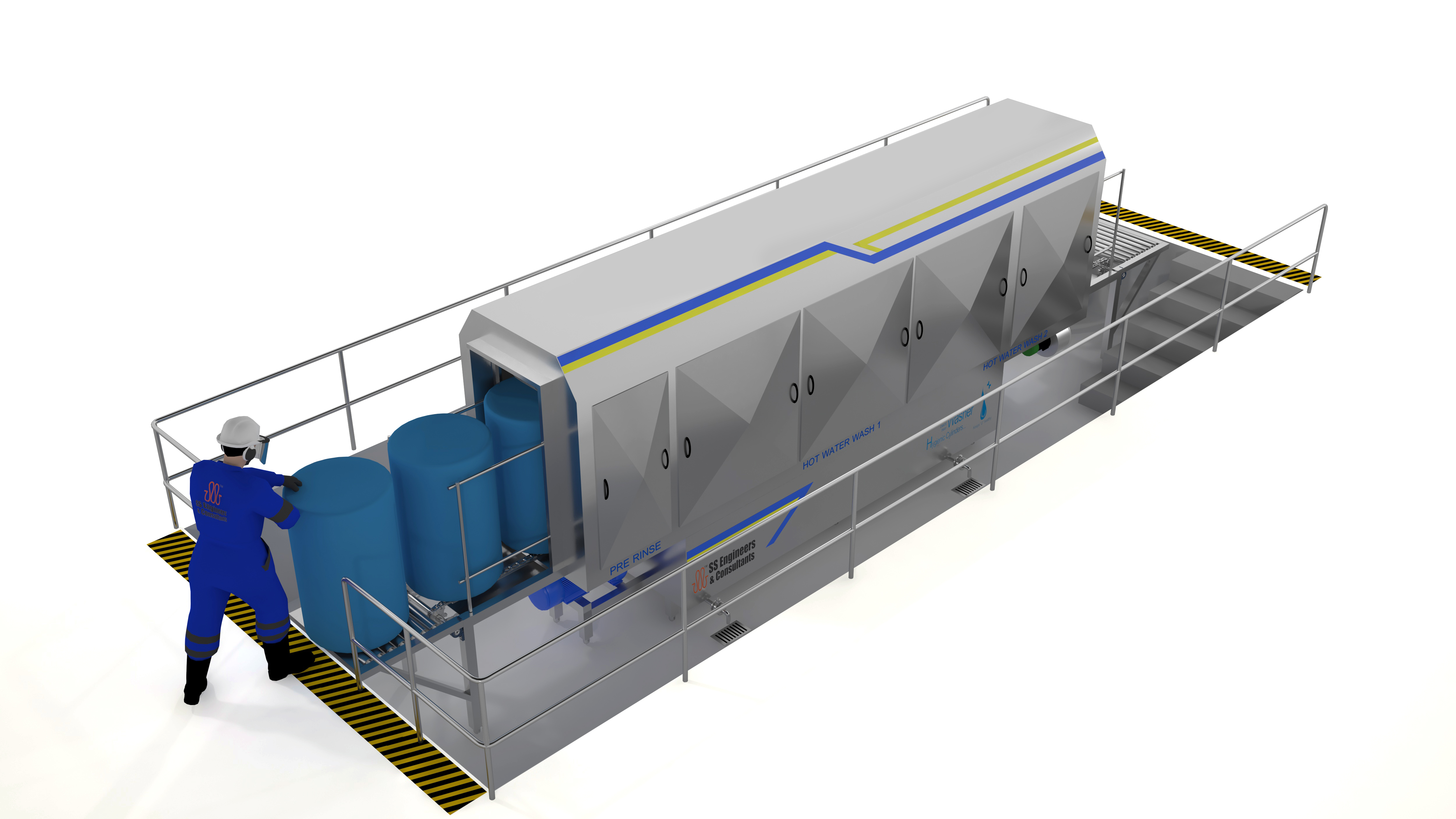

Crate Washer

Our Crate Washer is engineered for high-throughput cleaning of plastic crates, bins, and trays used across automobile, FMCG, and component manufacturing. The tunnel features staged pre-rinse → detergent wash → fresh-water rinse → optional sanitizer → high-velocity air blow-off, delivering consistent results while conserving water and chemicals through closed-loop filtration and recirculation.

With configurable nozzle manifolds, adjustable belt speed, and recipe control, the line handles mixed soils—oils, cutting fluids, dust, and road grime—without cross-contamination. Hygienic SS304/316 construction, inline basket filters, wedge-screen fines removal, and auto-dosing keep OPEX low. Typical capacity is up to 500 crates/hour (scalable with multi-lane options), making it ideal for centralized washing near assembly and packaging areas.

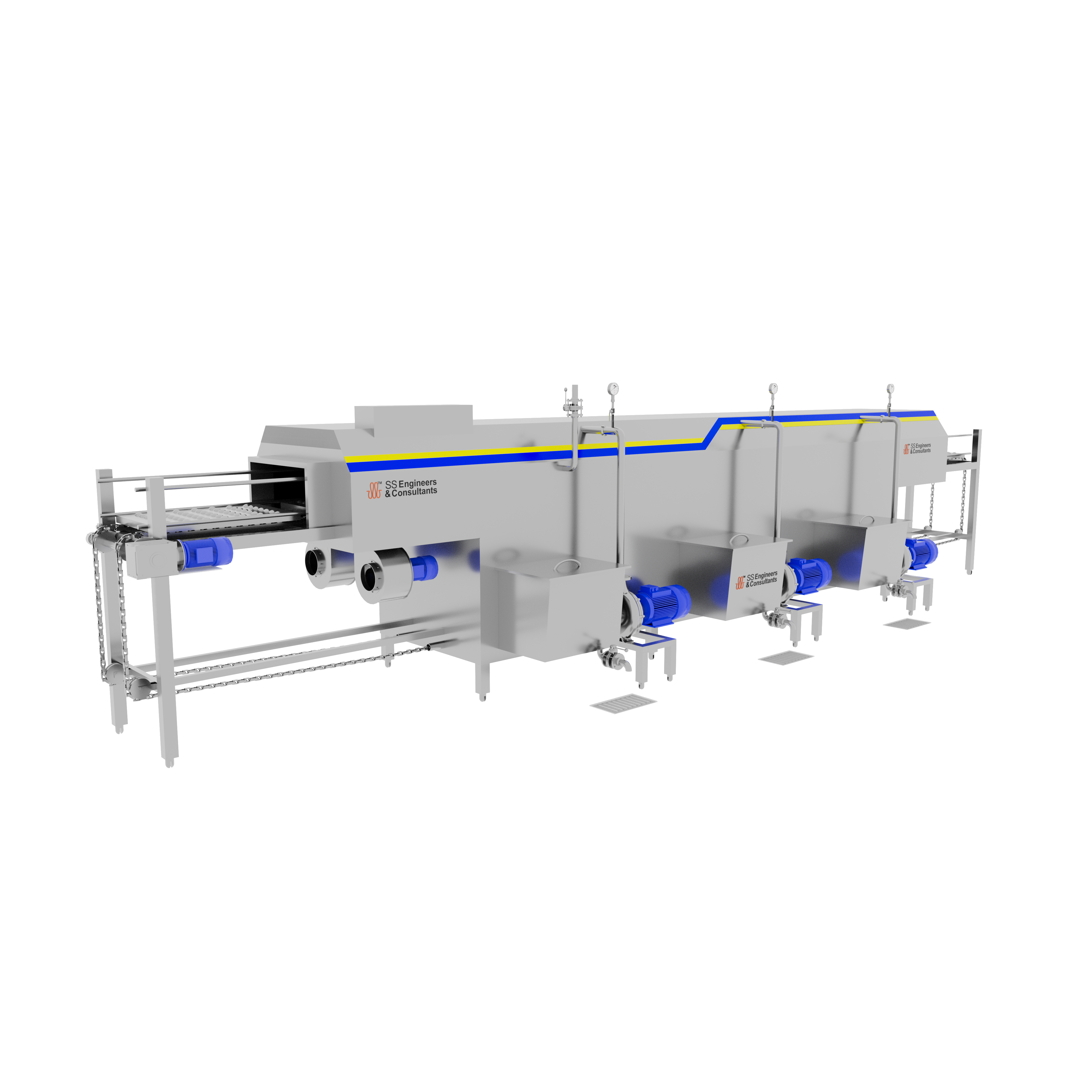

Pallet Washer

The Pallet Washer is a heavy-duty system for cleaning plastic and metal pallets (e.g., 1200×1000, 1200×800) used in warehousing and automotive logistics. A reinforced tunnel with powered infeed centers the pallet and drives it through pre-soak, high-pressure wash, hot fresh-water rinse, and turbo air-knife drying. Overspray capture, cyclone mist extraction, and dual-stage filtration enable long bath life and clean discharge.

Options include single or dual lanes, label/adhesive removal jets, TDS/temperature control, conductivity-based rinse make-up, and integrated return conveyors. The design minimizes carry-over, prevents pooling, and ensures pallets exit dry and ready for reuse, improving hygiene and turnaround in high-volume distribution centers.

Our Drum Washer is purpose-built for 20–220 L drums and pails used for oils, coolants, paints, and chemicals. Internal rotary spray heads scour the interior while exterior fan jets remove residues from chimes and walls. Configurable cycles support alkaline or neutral detergents, ambient or heated wash, and final DI/fresh-water rinse to achieve repeatable cleanliness before re-use or recycling.

Safety and uptime are central: sealed wash chamber with interlocks, vapor extraction, sludge capture trays, optional ATEX-ready components for solvent-compatible layouts, and auto-dose/auto-fill utilities. Quick-change bung fixtures and recipe recall help operators switch SKUs rapidly while maintaining documented quality standards.

The Conveyor System integrates upstream washers and downstream packing/assembly for a seamless material flow. We supply modular belt, roller, chain, gravity, Z-elevators, curved, and accumulation conveyors with smart controls for metering, singulation, merging, diverting, and buffering. Sensors, VFDs, and PLC logic coordinate speeds to eliminate bottlenecks and protect sensitive parts.

Layouts can include inspection stations, reject spurs, line-side kitting, and pallet/crate return loops. Stainless or coated mild-steel frames, food-grade belts where required, and tool-less access for sanitation/maintenance reduce downtime. The result is a safe, ergonomic, and scalable transfer backbone for high-mix manufacturing and warehousing.

The Vessel Washer automates internal and external cleaning of kettles, mixing vessels, totes, and carts. Compact cabinets or open-frame skids deploy oscillating spray arms and 360° rotating heads to break films and residues rapidly. Programmed cycles cover pre-rinse, heated detergent wash, recirculated rinse, and final fresh-water polish with optional sanitizer, ensuring repeatable results with minimal water footprint.

Sanitary piping, smooth welds, and easy-lift fixturing deliver fast changeovers. Flow, temperature, and conductivity are monitored for quality assurance; recipe and batch data can be logged for traceability. Choose SS304/316 wetted parts, double-wall insulated tanks, and energy-efficient pumps to meet stringent hygiene and productivity goals.

Designed for confectionery and bakery operations, the Laddu Tray Washer removes sticky sugars, ghee/oils, and starch residues from aluminium and SS trays. A compact tunnel with angled jet geometry targets corners and flanges, while oscillating manifolds lift stubborn deposits without damaging the tray surface. Heated wash, controlled detergent dosing, and fresh-water final rinse deliver spotless, repeatable outcomes.

Stack-in/stack-out handling, quick-change guides for multiple tray sizes, and high-velocity blowers reduce moisture carry-over so trays re-enter production faster. The system’s small footprint, easy-open panels, and tool-less screens simplify daily cleaning, ensuring hygiene, throughput, and cost control for sweet production lines.