Categories

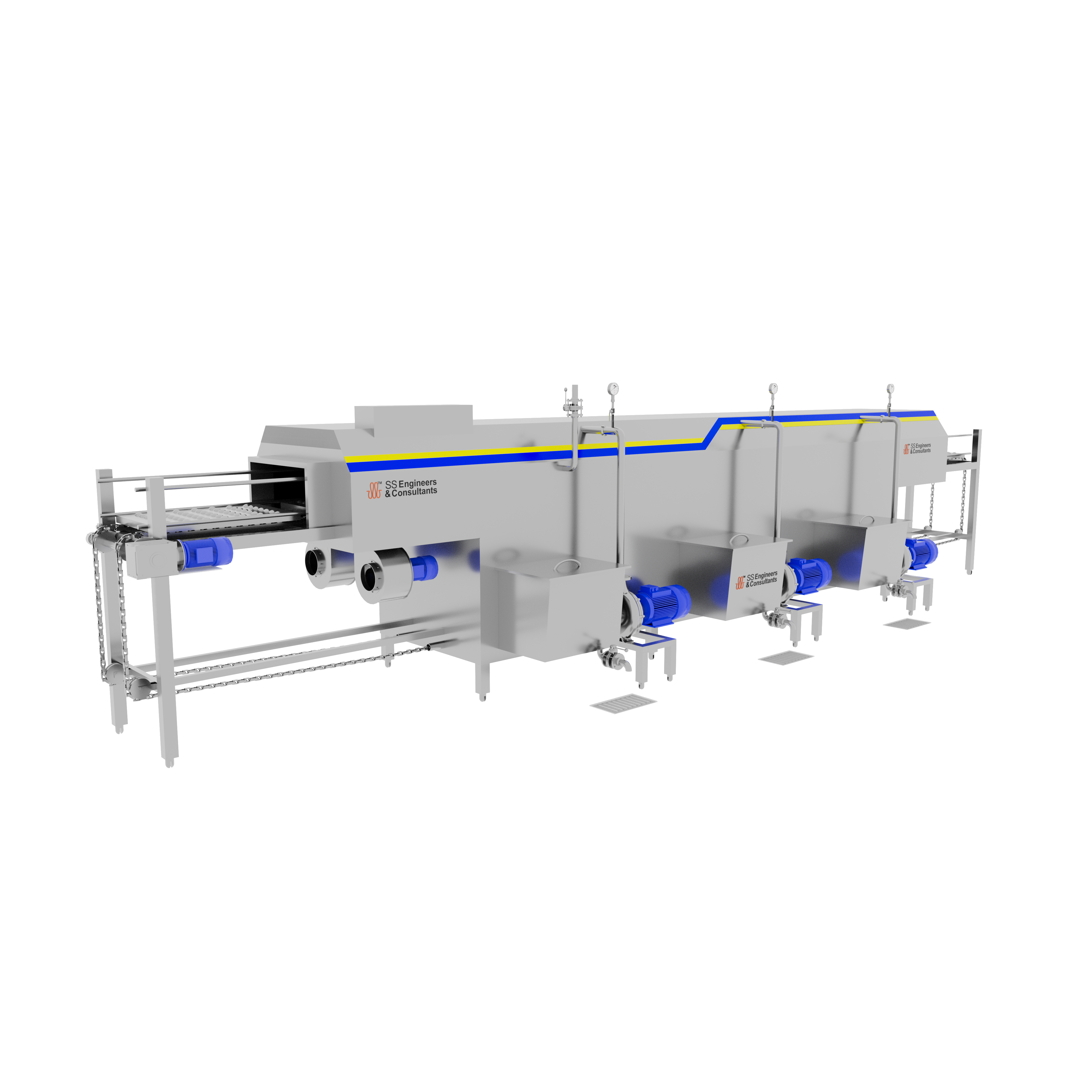

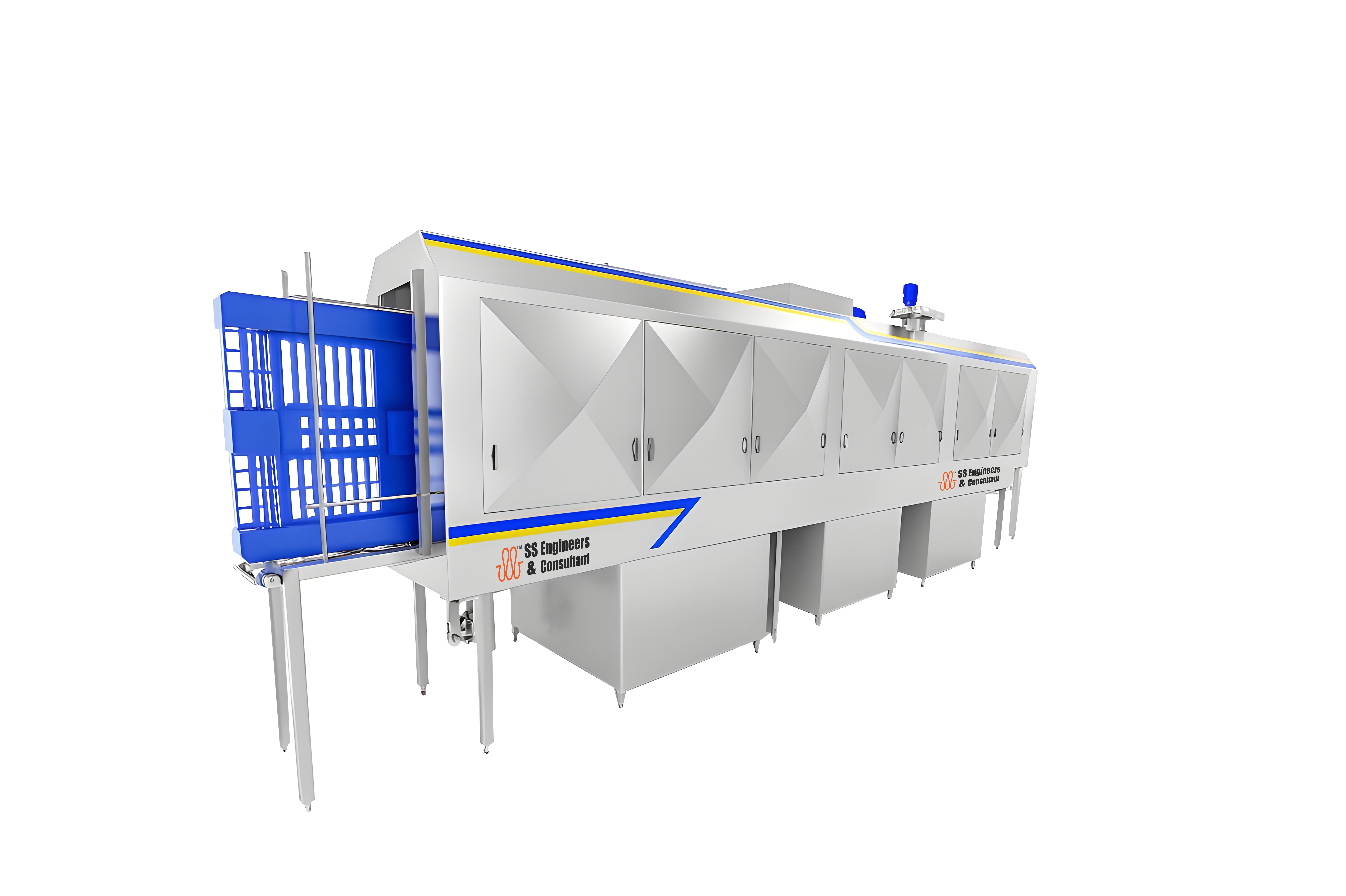

Pallet Washer

SS Engineers & Consultants design and manufacture advanced pallet washing systems purpose-built for bakeries

and confectionery industries where hygiene, speed, and reliability are critical. Our pallet washers are

engineered in SS304/316 with sanitary welds, food-grade gaskets, and robust construction to withstand continuous

operation in demanding environments. These machines are ideal for cleaning plastic and stainless-steel pallets

used for transporting raw materials (flour, sugar, chocolate blocks, oils) as well as finished goods (bread,

buns, cakes, biscuits, confectionery).

Each washer is configured with multi-stage cleaning zones – pre-wash for loosening heavy flour dust and residues, detergent wash for fat, oil, and sugar syrup removal, fresh water rinse for chemical-free finish, and an optional hot-rinse/sanitizing zone at 82–85 °C for microbiological safety. High-impact spray nozzles are positioned to cover all pallet surfaces, including edges and undersides, ensuring uniform cleaning performance at adjustable conveyor speeds.

The system incorporates CIP-ready wash tanks with automatic filtration to remove debris, auto-dosing units for precise chemical consumption, and inline temperature controllers to maintain consistent washing conditions. Sloped hygienic surfaces guarantee complete drainage, preventing bacterial growth. Easy-open maintenance doors and tool-free nozzle access reduce downtime for cleaning and servicing.

Each washer is configured with multi-stage cleaning zones – pre-wash for loosening heavy flour dust and residues, detergent wash for fat, oil, and sugar syrup removal, fresh water rinse for chemical-free finish, and an optional hot-rinse/sanitizing zone at 82–85 °C for microbiological safety. High-impact spray nozzles are positioned to cover all pallet surfaces, including edges and undersides, ensuring uniform cleaning performance at adjustable conveyor speeds.

The system incorporates CIP-ready wash tanks with automatic filtration to remove debris, auto-dosing units for precise chemical consumption, and inline temperature controllers to maintain consistent washing conditions. Sloped hygienic surfaces guarantee complete drainage, preventing bacterial growth. Easy-open maintenance doors and tool-free nozzle access reduce downtime for cleaning and servicing.

Key Features :

- Heavy-duty SS304/316 hygienic construction with sanitary welds and sloped drain design

- Multi-zone cleaning (pre-wash, detergent wash, rinse, hot rinse) tailored for flour dust, chocolate, syrups, oils/fats, and allergen residues

- Compatible with multiple pallet types (plastic, SS) with recipe-based wash cycles for varied bakery and confectionery applications

- Optional hot rinse/sanitization at 82–85 °C ensuring HACCP, FSMS, and international food safety compliance

- Integrated CIP-ready tanks with automatic filtration, chemical dosing, and optimized water/heat recovery to reduce OPEX

- PLC/SCADA automation with recipe management, conveyor speed control, and data logging for traceability

- Optional air-knife or blower drying modules for faster turnaround, enabling immediate reuse of pallets in production or cold storage

- Ergonomic, easy-access design with tool-free nozzle removal and quick maintenance features for reduced downtime

See it in Action

Youtube Video Auto Playing without sound