Categories

Conveyor System

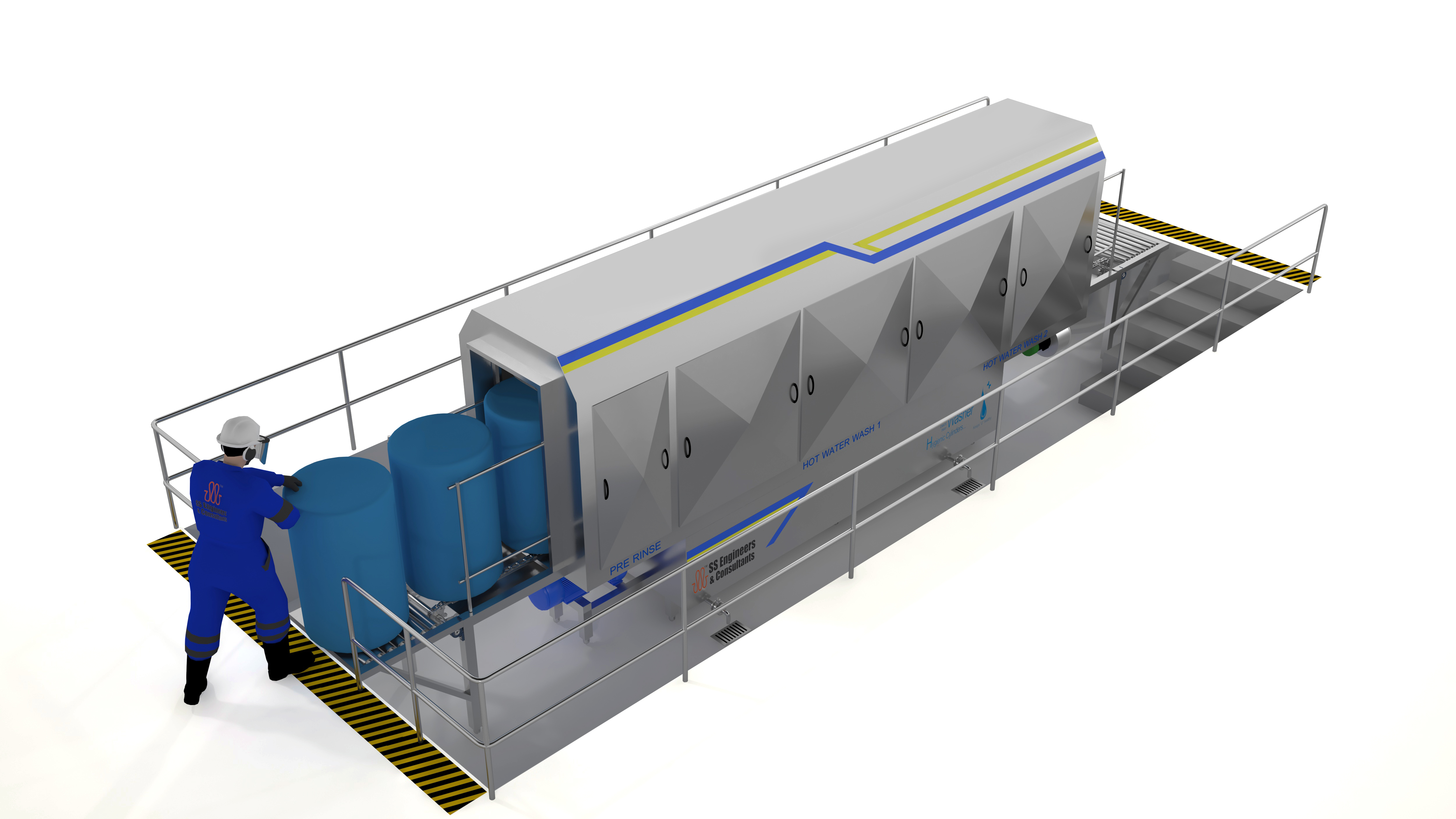

SS Engineers & Consultants deliver robust, hygienic, and high-efficiency conveyor systems engineered

for bakery, dairy, beverage, and food processing industries. Fabricated in SS304/316 with food-grade

belts, precision bearings, and sanitary welds, our conveyors provide seamless transfer of crates, trays,

bins, cartons, and packaged products. Designed to withstand flour dust, oils, syrups, chocolate

residues, and moisture-rich environments, they ensure long-lasting performance with minimal downtime.

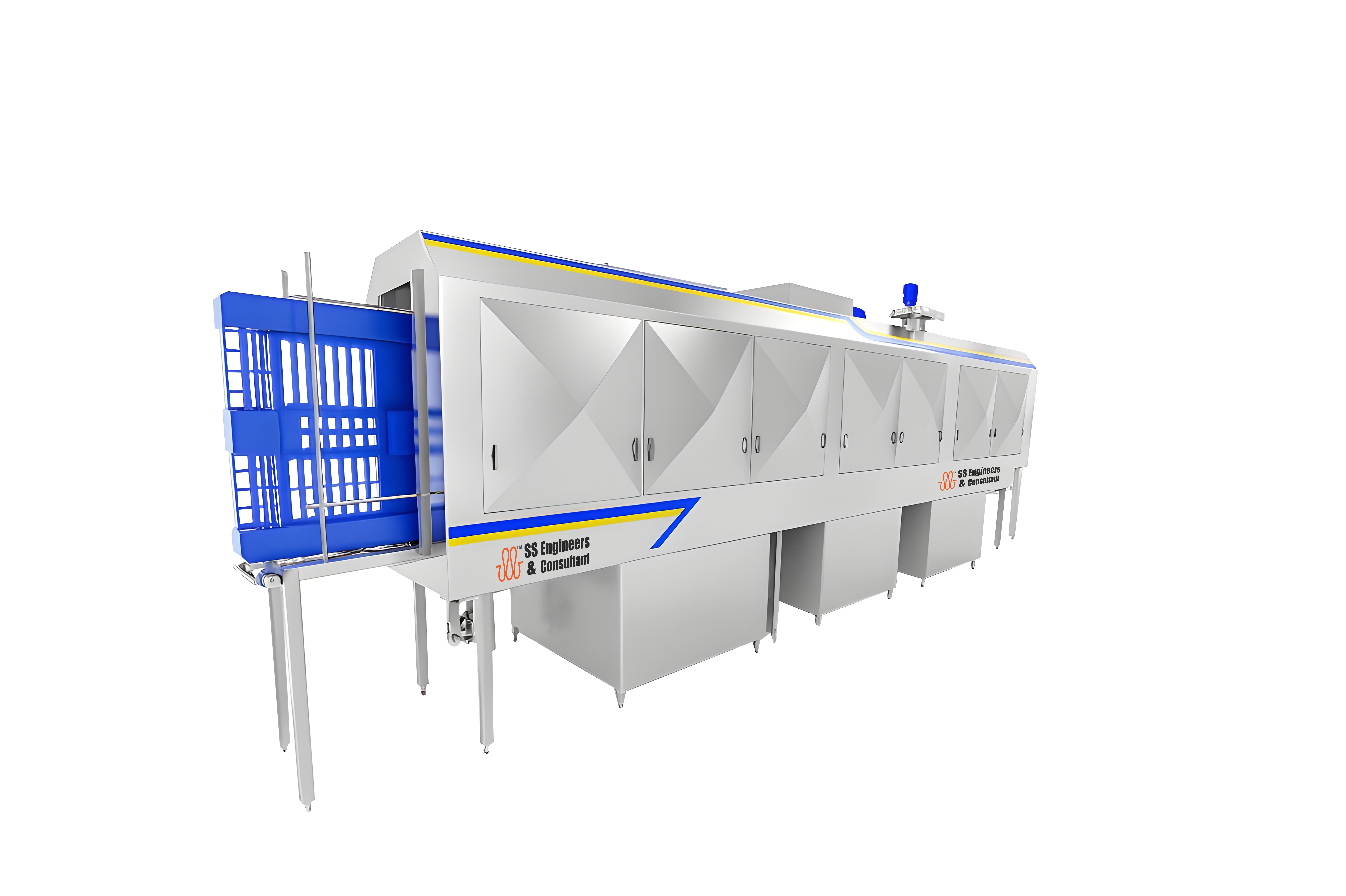

Our conveyor range covers flat-belt, modular plastic belt, slat chain, gravity/ powered roller, wire mesh, and spiral conveyors, each configured for applications such as dough-proofing trays, bread crates, confectionery handling, frozen goods, and secondary packaging. Heavy-duty drive assemblies with VFD-controlled motors enable smooth, variable-speed operation while low-noise, energy-efficient systems reduce operational costs.

Features include tool-free belt removal for quick sanitation, CIP-ready frames with integrated spray headers, auto-lubrication systems, inline temperature and load monitoring sensors, and hygienic sloped surfaces to avoid residue accumulation. Our conveyors are PLC/SCADA integrated with recipe management, automated start/stop logic, and batch/continuous operation modes for different SKUs. Advanced options such as accumulation zones, automatic diverters, merging/sorting modules, retractable conveyors, and incline/decline sections provide unmatched flexibility in layout design.

Designed to meet HACCP, FSMS, and CE Machinery Directive requirements, these conveyors are fully compatible with modern digital manufacturing practices, offering smart connectivity with ERP/SAP systems. Ergonomic operator interfaces, safety interlocks, and transparent guards ensure ease of use and compliance with international safety norms.

Optional add-ons such as air-knife blow-off units, stainless steel side guards, quick-adjust guide rails, and integrated weighing/labeling modules enable faster turnaround from processing to packaging areas. Whether in standalone bakery plants or large-scale automated food factories, our conveyor systems optimize throughput, minimize labor intensity, and reduce cleaning/maintenance time — delivering consistent, microbiologically safe results for continuous 24x7 operations.

Our conveyor range covers flat-belt, modular plastic belt, slat chain, gravity/ powered roller, wire mesh, and spiral conveyors, each configured for applications such as dough-proofing trays, bread crates, confectionery handling, frozen goods, and secondary packaging. Heavy-duty drive assemblies with VFD-controlled motors enable smooth, variable-speed operation while low-noise, energy-efficient systems reduce operational costs.

Features include tool-free belt removal for quick sanitation, CIP-ready frames with integrated spray headers, auto-lubrication systems, inline temperature and load monitoring sensors, and hygienic sloped surfaces to avoid residue accumulation. Our conveyors are PLC/SCADA integrated with recipe management, automated start/stop logic, and batch/continuous operation modes for different SKUs. Advanced options such as accumulation zones, automatic diverters, merging/sorting modules, retractable conveyors, and incline/decline sections provide unmatched flexibility in layout design.

Designed to meet HACCP, FSMS, and CE Machinery Directive requirements, these conveyors are fully compatible with modern digital manufacturing practices, offering smart connectivity with ERP/SAP systems. Ergonomic operator interfaces, safety interlocks, and transparent guards ensure ease of use and compliance with international safety norms.

Optional add-ons such as air-knife blow-off units, stainless steel side guards, quick-adjust guide rails, and integrated weighing/labeling modules enable faster turnaround from processing to packaging areas. Whether in standalone bakery plants or large-scale automated food factories, our conveyor systems optimize throughput, minimize labor intensity, and reduce cleaning/maintenance time — delivering consistent, microbiologically safe results for continuous 24x7 operations.

Key Features — Conveyor System:

- SS304/316 hygienic construction with sanitary welds and full-drain, wash-down geometry

- Multiple conveyor types: flat belt, modular plastic belt, slat chain, powered/gravity roller, and spiral

- VFD-driven motors with precise speed control, soft start/stop, and low-noise, energy-efficient drives

- Tool-free belt/roller access for fast cleaning; CIP-ready frames with integrated spray headers

- Sensors for product detection, jam/overload, and count; PLC/SCADA integration with recipe management

- Flexible layouts with curves, inclines/declines, merges, diverts, accumulation, and retractable sections

- Safety interlocks, emergency stops, guards, and IP-rated components to meet HACCP/FSMS & CE standards

- Optional add-ons: quick-adjust guide rails, air-knife blow-off, inline weighing/labeling, and IoT connectivity

See it in Action

Youtube Video Auto Playing without sound