Categories

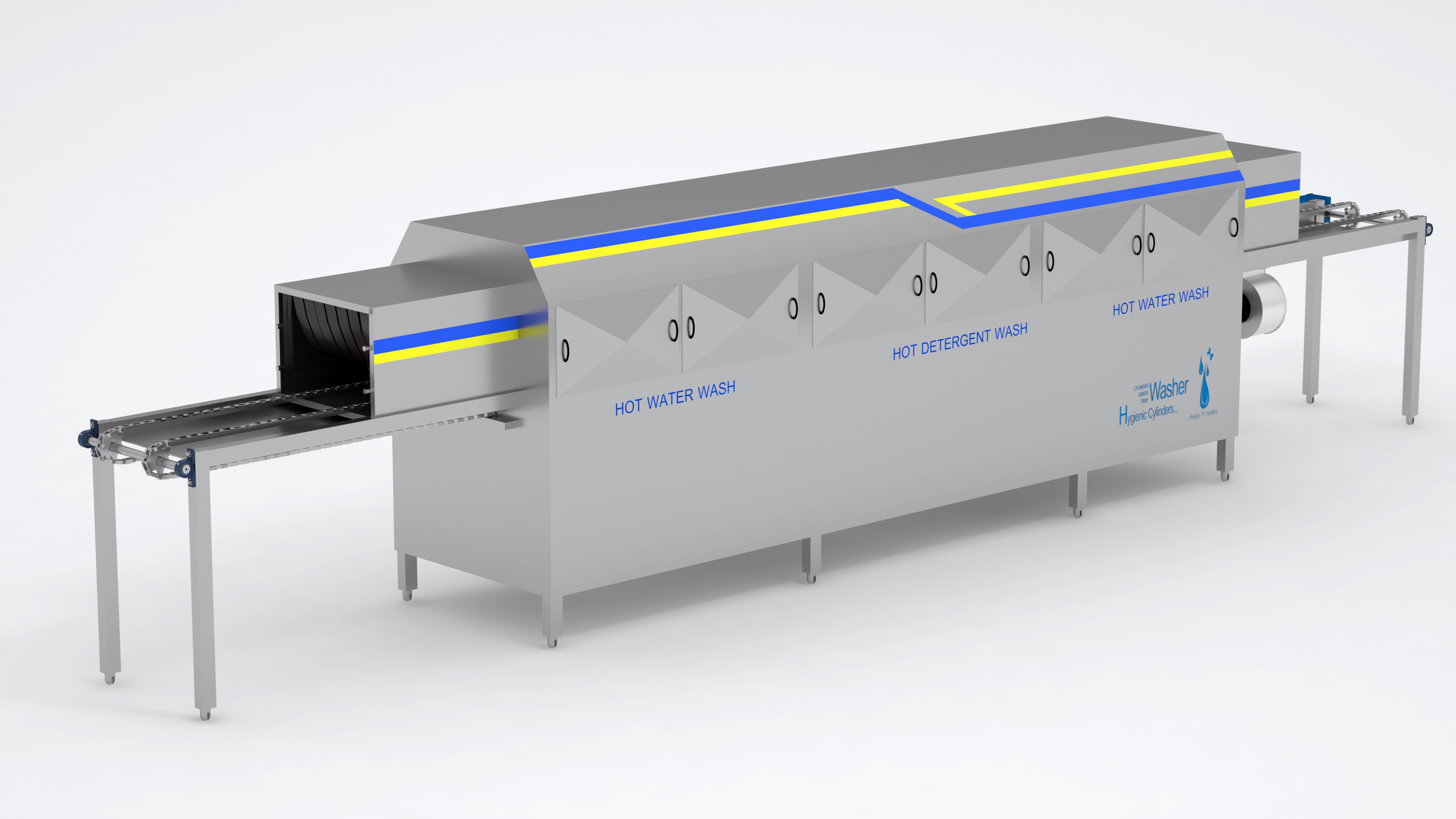

Vessel Washer

SS Engineers & Consultants manufacture heavy-duty, hygienic vessel washers designed for food, dairy,

beverage, pharmaceutical, and industrial applications. Fabricated in SS304/316 with sanitary welds,

food-grade seals, and sloped drainable surfaces, our vessel washers deliver reliable cleaning and

sanitization for a wide range of containers including mixing vessels, storage tanks, IBCs, totes,

fermentation tanks, and ingredient vessels. High-impact rotary spray heads and 360° coverage ensure

removal of product residues such as dairy films, starch deposits, syrups, sauces, oils/fats, powders,

and allergens.

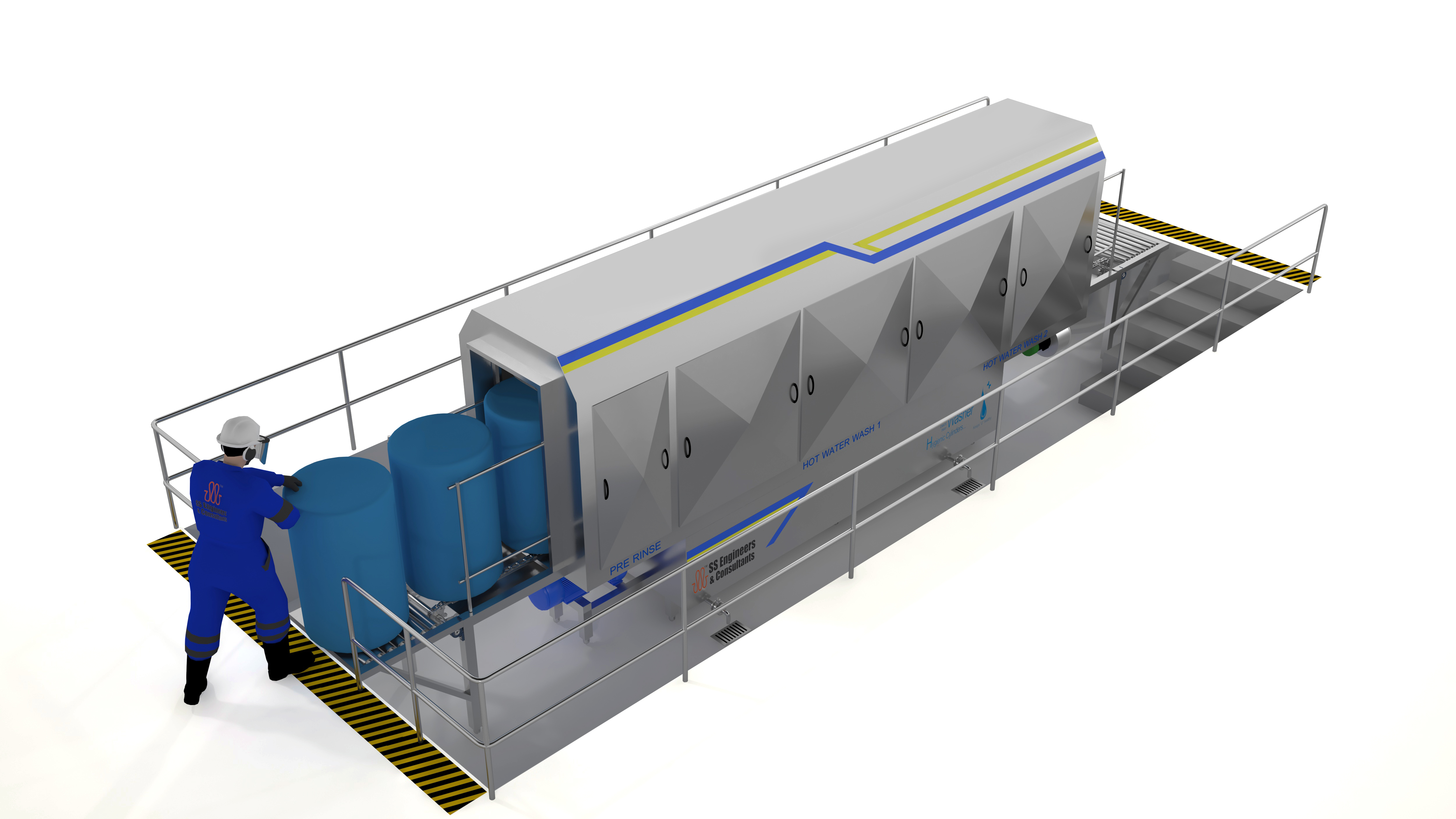

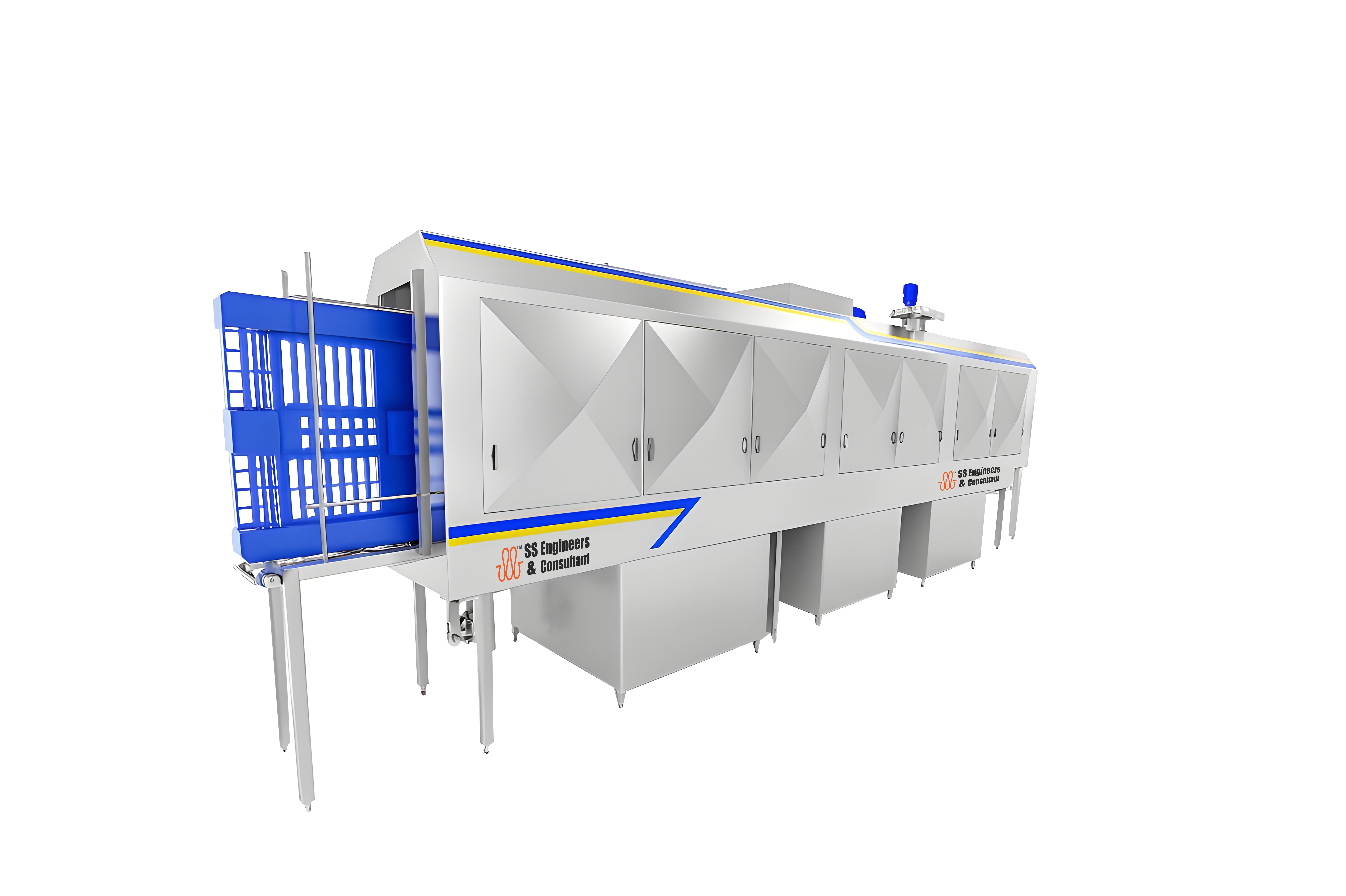

Multi-zone cleaning chambers (pre-wash, detergent wash, rinse, and optional hot-water/steam sanitization at 82–90 °C) are combined with adjustable wash pressures, CIP-ready pump/tank skids, and detergent auto-dosing to guarantee microbiologically safe and repeatable cleaning cycles. For pharmaceutical or high-care food facilities, vessels can be validated with integrated temperature and conductivity sensors, ensuring compliance with GMP, HACCP, FSMS, and FDA/EC standards.

Features include inline filtration, automated chemical dosing, energy-efficient heating, programmable cleaning recipes, and PLC/SCADA automation with data logging. Access hatches, sight glasses, and automated lifting/rotation mechanisms simplify inspection and reduce operator handling. Optional robotic loading arms or track-mounted conveyors allow seamless integration with high-throughput production lines.

Multi-zone cleaning chambers (pre-wash, detergent wash, rinse, and optional hot-water/steam sanitization at 82–90 °C) are combined with adjustable wash pressures, CIP-ready pump/tank skids, and detergent auto-dosing to guarantee microbiologically safe and repeatable cleaning cycles. For pharmaceutical or high-care food facilities, vessels can be validated with integrated temperature and conductivity sensors, ensuring compliance with GMP, HACCP, FSMS, and FDA/EC standards.

Features include inline filtration, automated chemical dosing, energy-efficient heating, programmable cleaning recipes, and PLC/SCADA automation with data logging. Access hatches, sight glasses, and automated lifting/rotation mechanisms simplify inspection and reduce operator handling. Optional robotic loading arms or track-mounted conveyors allow seamless integration with high-throughput production lines.

Key Features — Vessel Washer:

- SS304/316 hygienic fabrication with sanitary welds, sloped drainable surfaces, and robust frame design

- 360° rotary spray heads and high-pressure jets for effective removal of dairy films, syrups, starch, and residues

- Multi-zone cleaning cycles with pre-wash, detergent wash, rinse, and optional hot-water/steam sanitization

- CIP-ready tanks with inline filtration, detergent auto-dosing, and water/heat recovery for cost efficiency

- PLC/SCADA automation with programmable recipes, cycle validation, and real-time monitoring

- Integrated sensors for temperature, flow, and conductivity to ensure HACCP, GMP, and FSMS compliance

- Ergonomic loading options with lifting/rotation mechanisms or robotic handling for high-throughput plants

- Optional add-ons: air-knife blow-off drying, SIP modules, and data logging for 21 CFR Part 11 compliance

See it in Action

Youtube Video Auto Playing without sound