Categories

Drum Washer

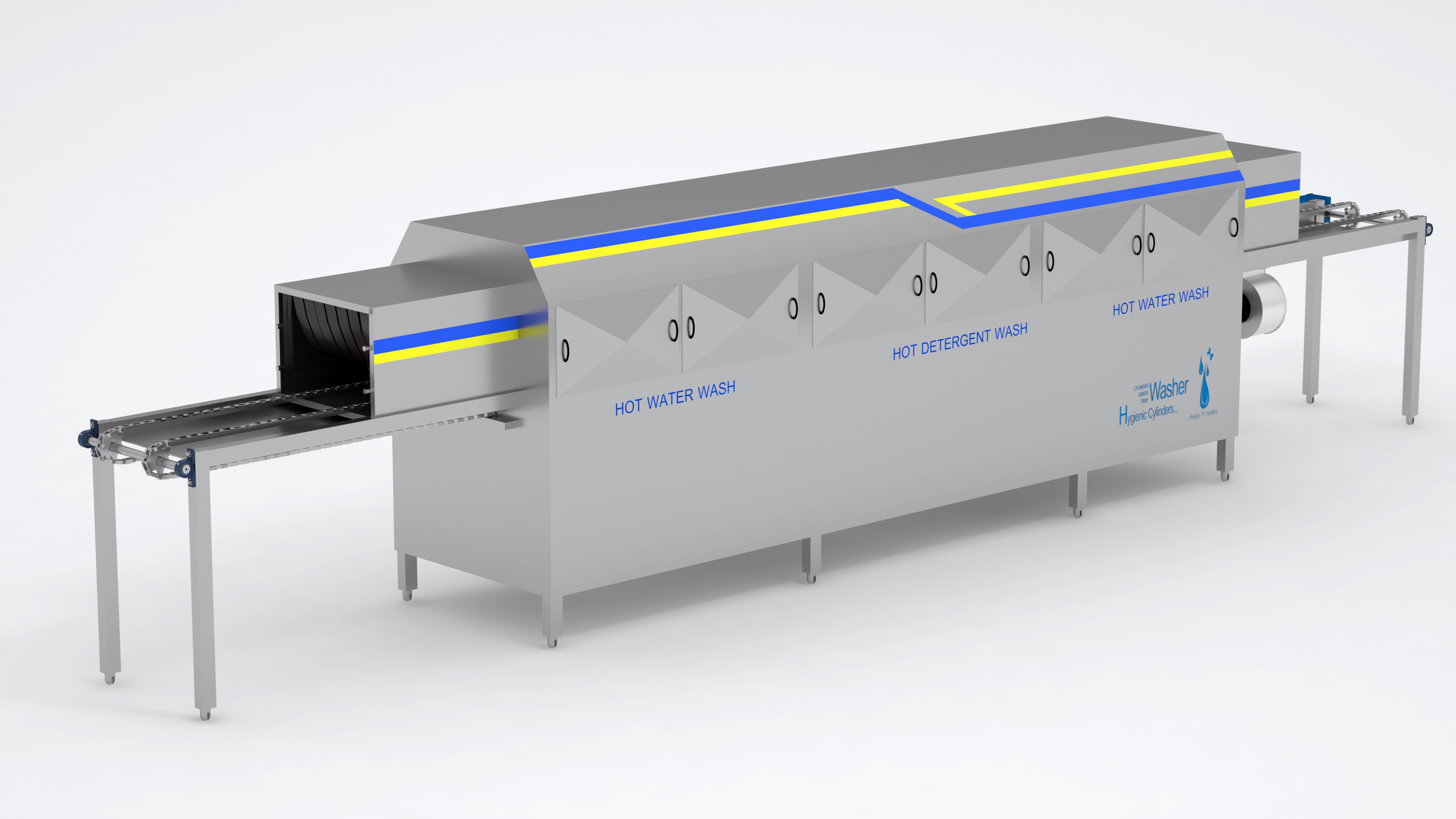

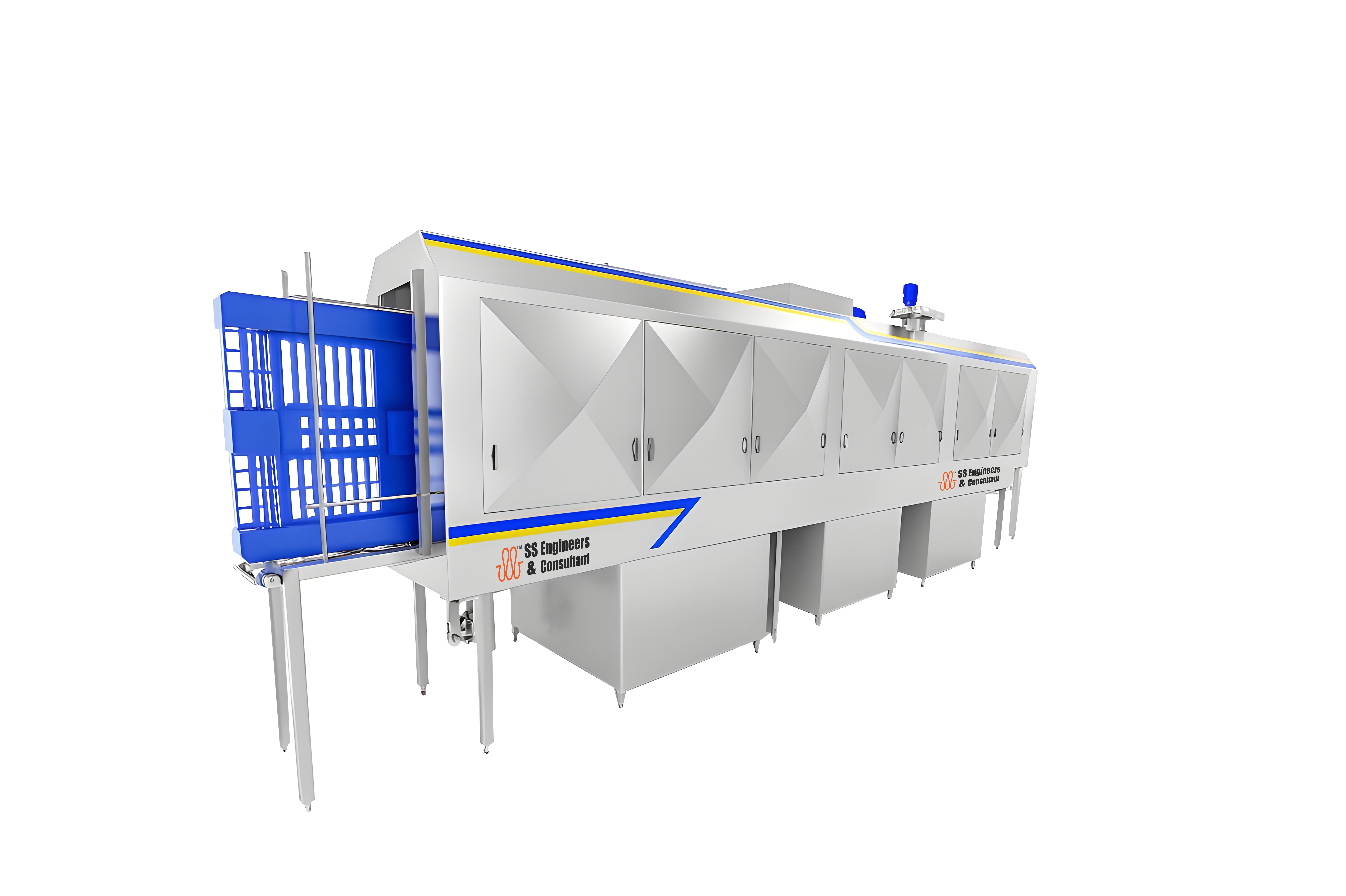

SS Engineers & Consultants provide advanced, high-throughput washing systems specifically designed for

bakery and confectionery drums, barrels, and ingredient containers. Built with SS304/316 stainless steel and

featuring food-grade seals and sanitary welds, our drum washers effectively remove stubborn residues such as

oils, fats, chocolate coatings, syrups, sugar, dairy ingredients, and allergens, ensuring that your production

environment stays hygienic and safe. These washers are ideal for drums and barrels used in mixing, transporting,

or storing raw ingredients, dough, syrups, and other bakery materials.

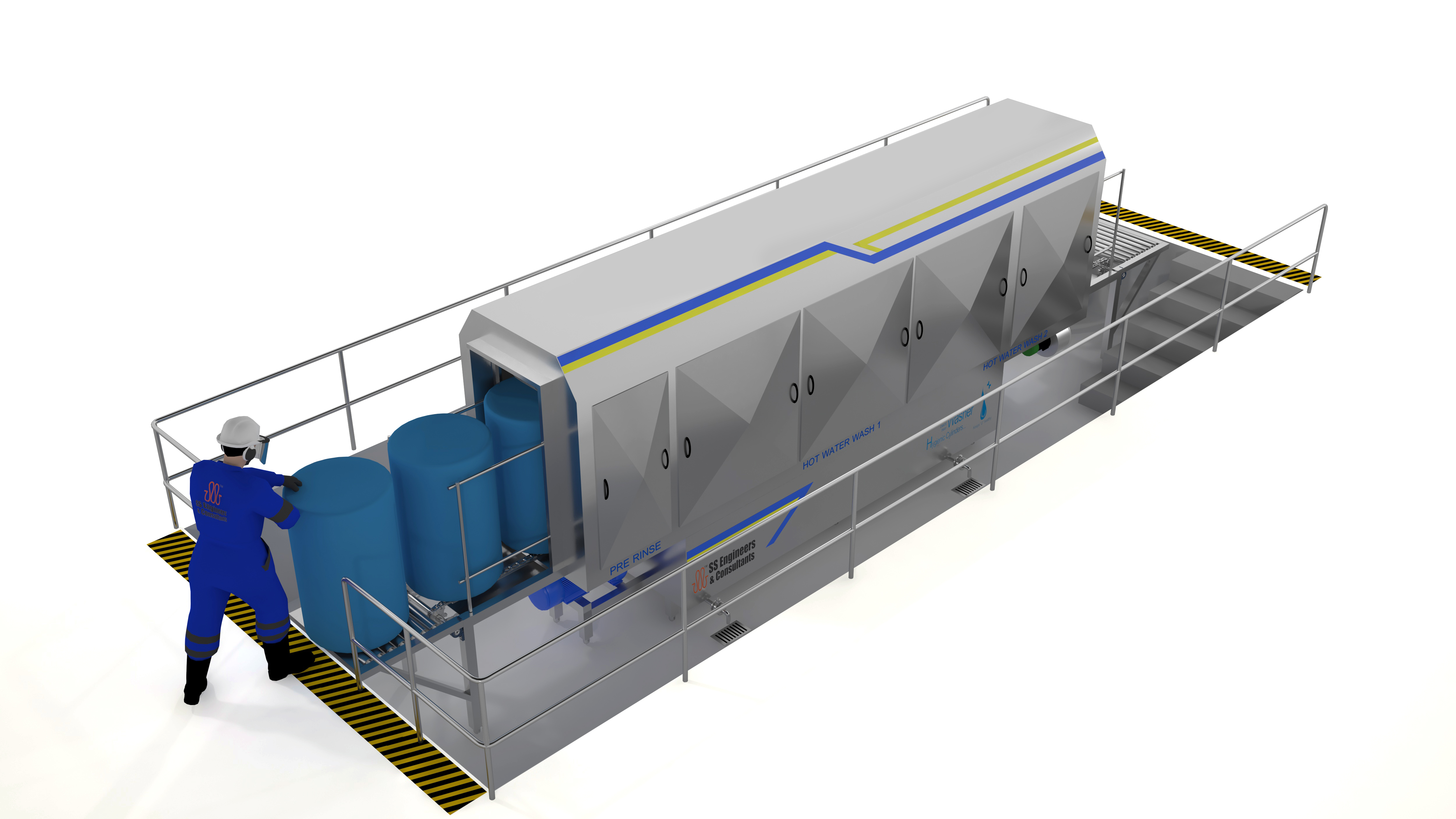

The system features multi-zone washing chambers, including a pre-wash stage to loosen and remove heavy residues, a detergent wash to tackle grease and sugar build-up, and a rinse cycle for thorough residue removal. For the most demanding food safety applications, an optional hot-rinse or sanitization cycle is available, operating at 82–85°C to eliminate microbial contaminants. The combination of high-impact rotary spray nozzles and adjustable conveyor speeds ensures complete and uniform cleaning, with minimal water, chemical, and energy consumption.

Designed with operational efficiency in mind, the drum washer comes with CIP-ready tanks that incorporate filtration systems to maintain wash water quality, automatic chemical dosing for precise detergent management, and inline temperature controls to maintain optimal washing conditions. The hygienic sloped surfaces facilitate complete drainage of water and cleaning agents, preventing bacterial growth. Additionally, the washer’s easy-access maintenance doors allow for quick and hassle-free servicing, reducing downtime and improving production efficiency.

For fast turnaround times and increased throughput, the drum washer can be fitted with optional air-knife blow-off systems or heated drying modules. These features reduce residual moisture, enabling cleaned drums to be returned to the production, storage, or packaging areas immediately. With full PLC/SCADA automation, recipe management functionality for different drum sizes and soil loads, and data logging for full traceability, this drum washer ensures that your bakery or confectionery operation remains compliant with HACCP, FSMS, and other global food safety standards.

Whether you need to clean ingredient drums, storage barrels, or equipment containers used in your bakery or confectionery production, our drum washer delivers consistent, microbiologically safe results, ensuring that your production lines remain hygienic, efficient, and compliant.

The system features multi-zone washing chambers, including a pre-wash stage to loosen and remove heavy residues, a detergent wash to tackle grease and sugar build-up, and a rinse cycle for thorough residue removal. For the most demanding food safety applications, an optional hot-rinse or sanitization cycle is available, operating at 82–85°C to eliminate microbial contaminants. The combination of high-impact rotary spray nozzles and adjustable conveyor speeds ensures complete and uniform cleaning, with minimal water, chemical, and energy consumption.

Designed with operational efficiency in mind, the drum washer comes with CIP-ready tanks that incorporate filtration systems to maintain wash water quality, automatic chemical dosing for precise detergent management, and inline temperature controls to maintain optimal washing conditions. The hygienic sloped surfaces facilitate complete drainage of water and cleaning agents, preventing bacterial growth. Additionally, the washer’s easy-access maintenance doors allow for quick and hassle-free servicing, reducing downtime and improving production efficiency.

For fast turnaround times and increased throughput, the drum washer can be fitted with optional air-knife blow-off systems or heated drying modules. These features reduce residual moisture, enabling cleaned drums to be returned to the production, storage, or packaging areas immediately. With full PLC/SCADA automation, recipe management functionality for different drum sizes and soil loads, and data logging for full traceability, this drum washer ensures that your bakery or confectionery operation remains compliant with HACCP, FSMS, and other global food safety standards.

Whether you need to clean ingredient drums, storage barrels, or equipment containers used in your bakery or confectionery production, our drum washer delivers consistent, microbiologically safe results, ensuring that your production lines remain hygienic, efficient, and compliant.

Key Features – Drum Washer (Bakery & Confectionery):

- SS304/316 hygienic construction with sanitary welds and sloped surfaces for full drainage

- Multi-zone cleaning with pre-wash, detergent wash, rinse, and optional hot-rinse for oils, syrups, and allergens

- Recipe-based programs for various drum sizes, soil loads, and residue types (syrups, fats, chocolate, etc.)

- Hot rinse/sanitization (optional) at 82–85°C for microbiological safety and HACCP compliance

- Inline filtration systems to maintain wash water quality and reduce chemical usage

- Automatic detergent dosing for precise chemical management, optimizing cleaning efficiency

- PLC-based automation with recipe management, adjustable conveyor speeds, and full traceability

- Optional air-knife drying systems for faster turnaround, reducing residual moisture for immediate reuse

See it in Action

Youtube Video Auto Playing without sound

Need Custom Solutions?

Our team can develop specialized cleaning solutions tailored to your bakery hygiene requirements.

Contact Our Experts