Categories

Laddu Tray Washer

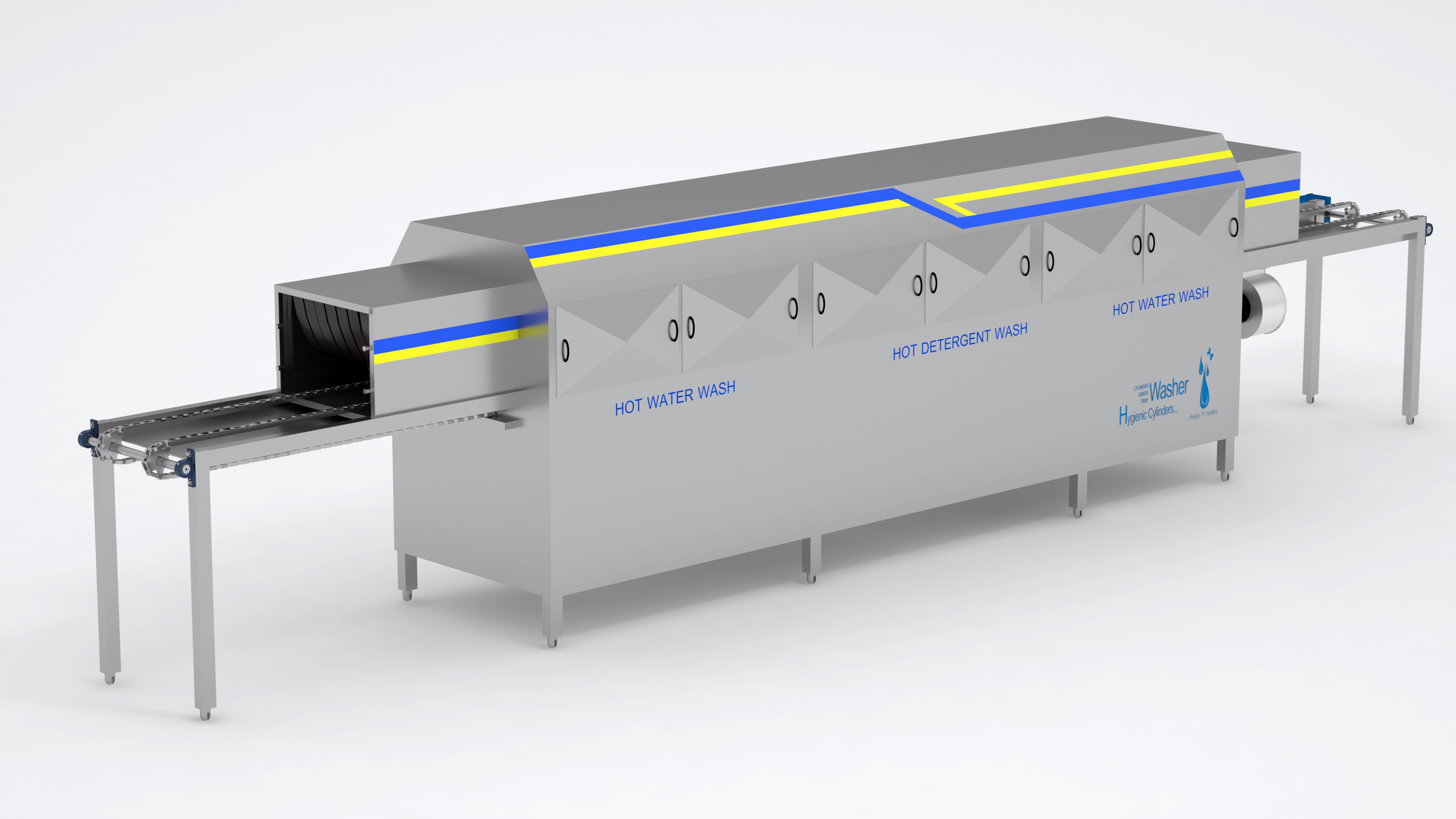

SS Engineers & Consultants design and manufacture hygienic, high-capacity laddu tray washers

engineered for Indian sweet and confectionery production lines. Constructed in SS304/316 with food-grade

seals and sanitary welds, these washers are purpose-built to clean trays used for laddus, barfi, peda,

and other traditional sweets. They effectively remove sticky sugar syrups, ghee/oil residues, flour

dust, nut particles, milk solids, and chocolate or coating carryover.

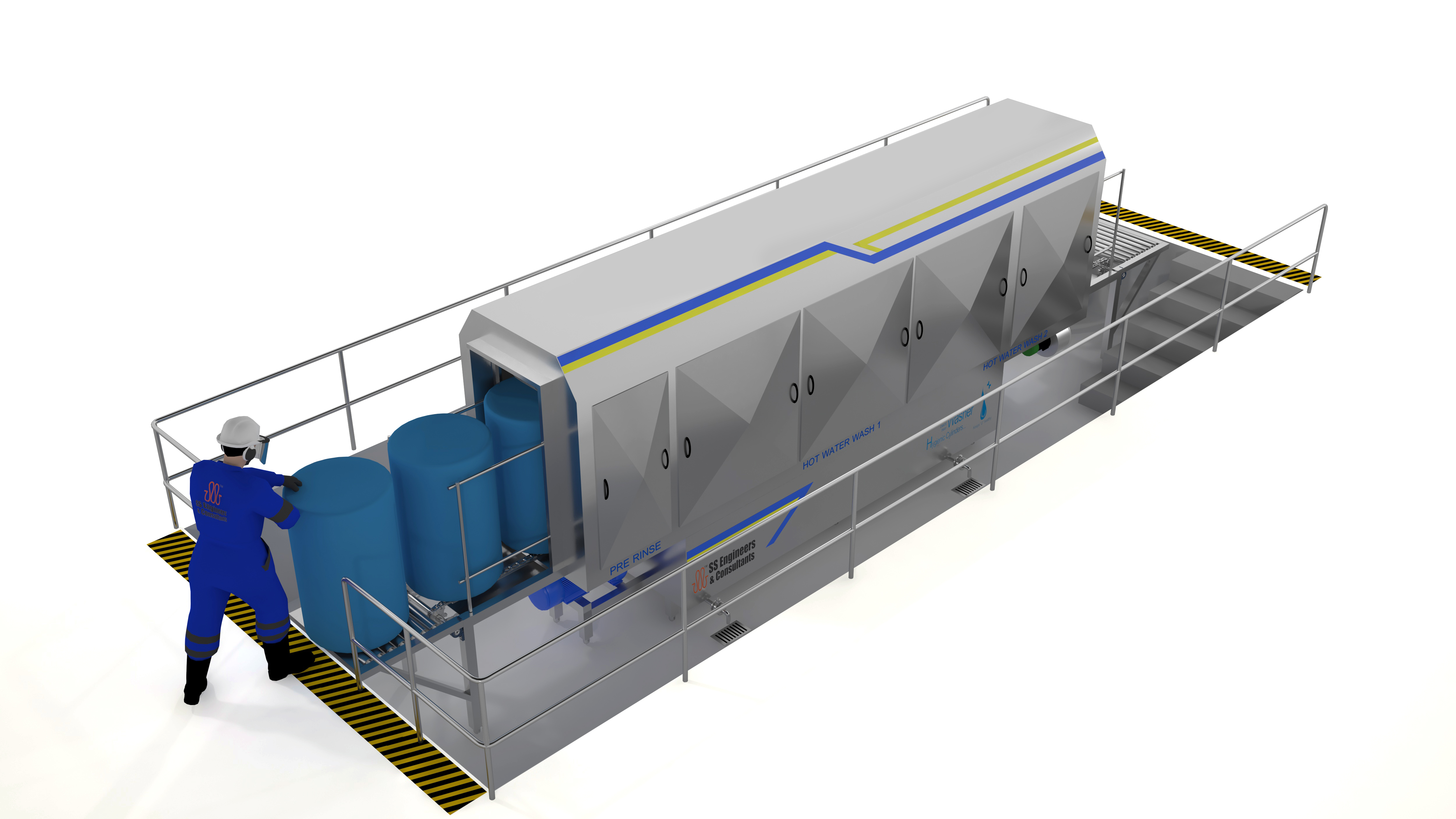

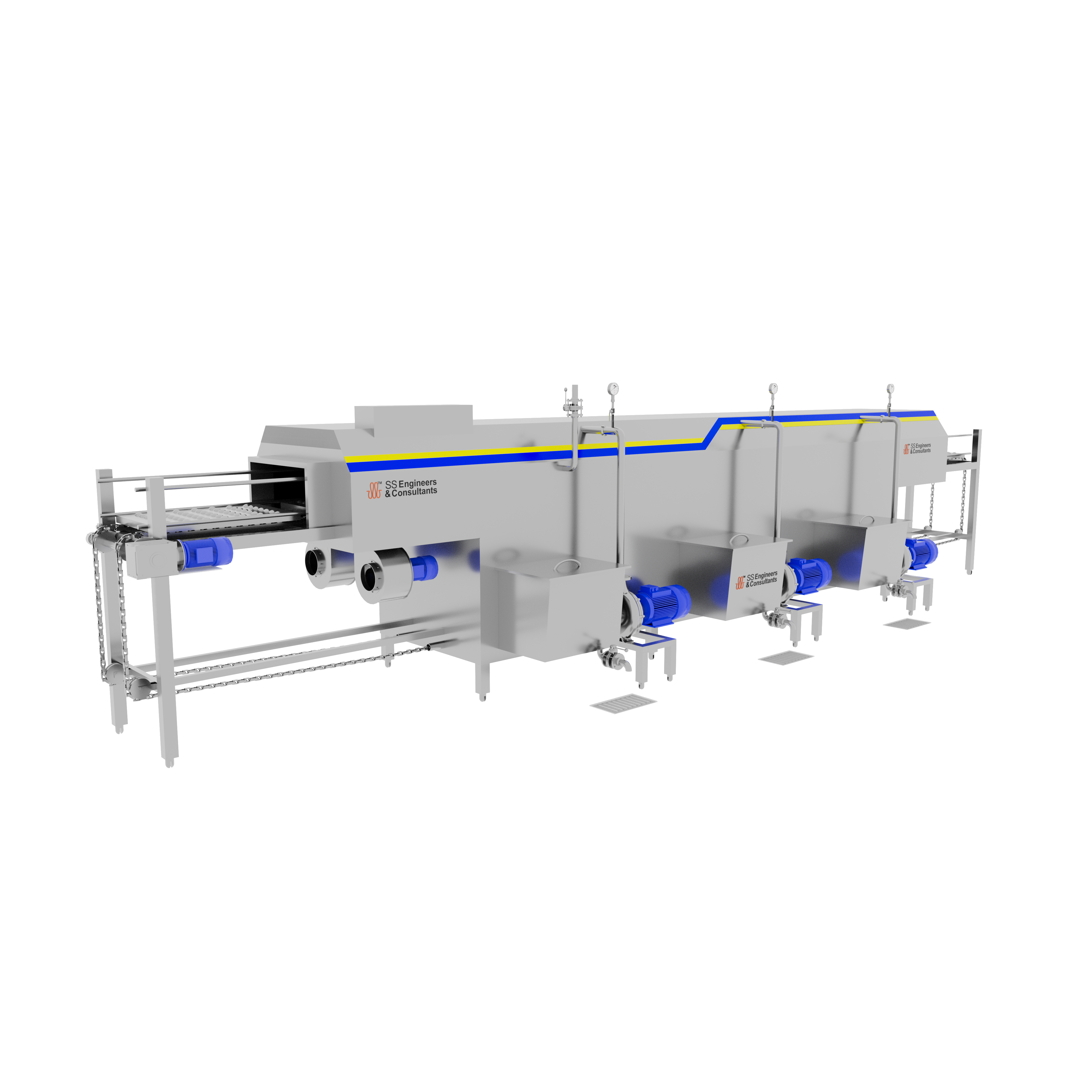

Multi-zone cleaning chambers (pre-wash, detergent wash, rinse, and optional hot-water/steam sanitization at 82–90 °C) use high-impact spray manifolds and rotary nozzles to ensure uniform coverage and deep cleaning. Adjustable conveyor speeds and programmable wash cycles allow customization for different tray sizes, shapes, and soil loads, guaranteeing consistent, microbiologically safe results while minimizing water, chemical, and energy consumption.

Key features include CIP-ready tanks with inline filtration, detergent auto-dosing, energy-efficient heating, and hygienic sloped surfaces for complete drainage. Operator-friendly design with easy-access doors and tool-free maintenance ensures minimum downtime. PLC/SCADA automation with recipe management allows bakeries and sweet manufacturers to run multiple cleaning programs for trays used across diverse products.

Optional modules such as hot-air or air-knife blow-off drying, allergen-control programs, and water/heat recovery systems enhance operational efficiency. For high-output facilities, tray washers can be integrated with conveyors, stacking/destacking units, or robotic loading arms to streamline production and packaging flows.

Multi-zone cleaning chambers (pre-wash, detergent wash, rinse, and optional hot-water/steam sanitization at 82–90 °C) use high-impact spray manifolds and rotary nozzles to ensure uniform coverage and deep cleaning. Adjustable conveyor speeds and programmable wash cycles allow customization for different tray sizes, shapes, and soil loads, guaranteeing consistent, microbiologically safe results while minimizing water, chemical, and energy consumption.

Key features include CIP-ready tanks with inline filtration, detergent auto-dosing, energy-efficient heating, and hygienic sloped surfaces for complete drainage. Operator-friendly design with easy-access doors and tool-free maintenance ensures minimum downtime. PLC/SCADA automation with recipe management allows bakeries and sweet manufacturers to run multiple cleaning programs for trays used across diverse products.

Optional modules such as hot-air or air-knife blow-off drying, allergen-control programs, and water/heat recovery systems enhance operational efficiency. For high-output facilities, tray washers can be integrated with conveyors, stacking/destacking units, or robotic loading arms to streamline production and packaging flows.

Key Features — Laddu Tray Washer:

- SS304/316 food-grade construction with sanitary welds and sloped, full-drain design

- High-pressure spray manifolds and rotary nozzles to remove sticky sugar, ghee, oil, and flour residues

- Multi-zone cleaning: pre-wash, detergent wash, rinse, and optional hot-water/steam sanitization at 82–90 °C

- Programmable recipes for different tray sizes, shapes, and soil loads used in sweets and bakery lines

- CIP-ready tanks with inline filtration, chemical auto-dosing, and water/heat recovery for lower operating costs

- PLC/SCADA automation with cycle logging, conveyor speed adjustment, and recipe management

- Optional air-knife or hot-air blow-off system for quick drying and allergen control in confectionery operations

- Designed for HACCP/FSMS compliance, ensuring hygienic, safe, and repeatable cleaning for sweet production trays

See it in Action

Youtube Video Auto Playing without sound